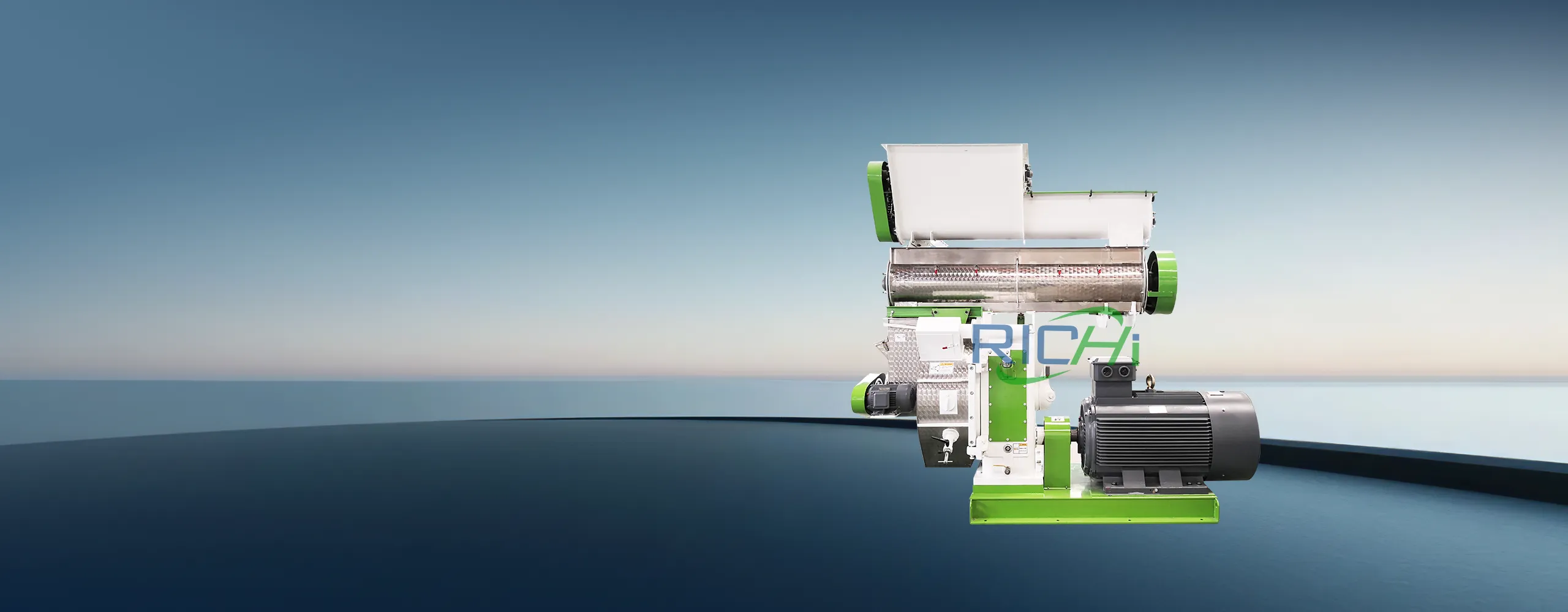

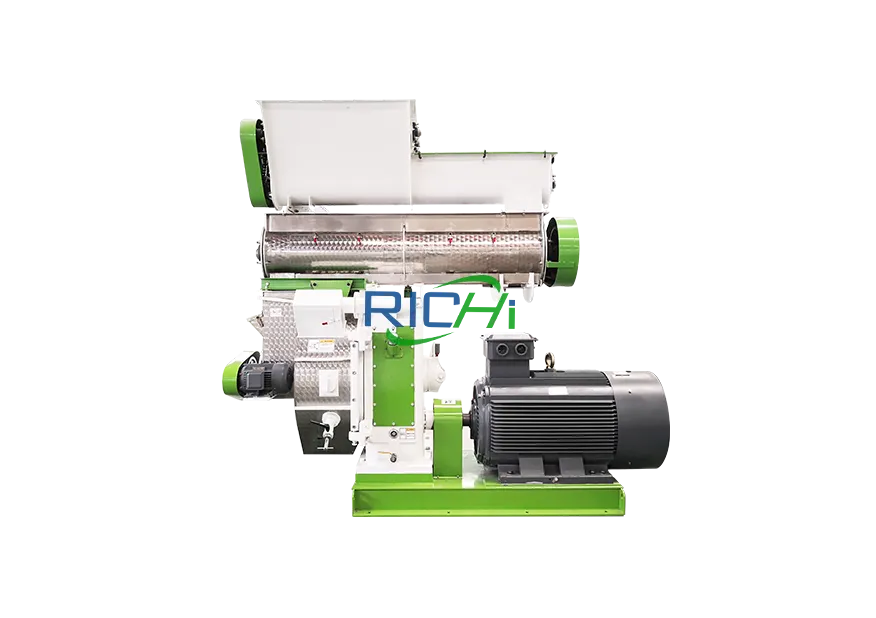

Goat Feed Pellet Making Machine

Major Challenges of Goat Feed Pellet Machines

Raw Material Processing

If a goat feed pellet making machine cannot process raw materials with high crude fiber content and diverse mineral content simultaneously, it will result in loose pellets.

Overall Machine Structure

Raw material characteristics place higher demands on goat pellet mill structure. Feeder, conditioner, pelletizing chamber, and base must integrate tightly to boost stability and cut noise.

Limited Models

Goats’ diet includes common forage, ordinary grains, proteins and premixes. However, most single-model pellet mills cannot effectively pelletize this mixed material.

Short Service Life

The increased fiber content leads to increased wear on the ring die and rollers. This often results in a short service life for many pellet mills of inferior quality.

When purchasing a pellet mill, you need to review information regarding raw material usage, mechanical structure, model types, and construction materials to help you quickly determine whether a particular brand of pellet mill avoids the four types of problems mentioned earlier.

Additionally, you can request more precise and accurate relevant data from the company through detailed inquiries, which is the most reliable and convenient method.

The RICHI goat feed pellet machine solves all the problems mentioned above, providing you with a better pelletizing experience.

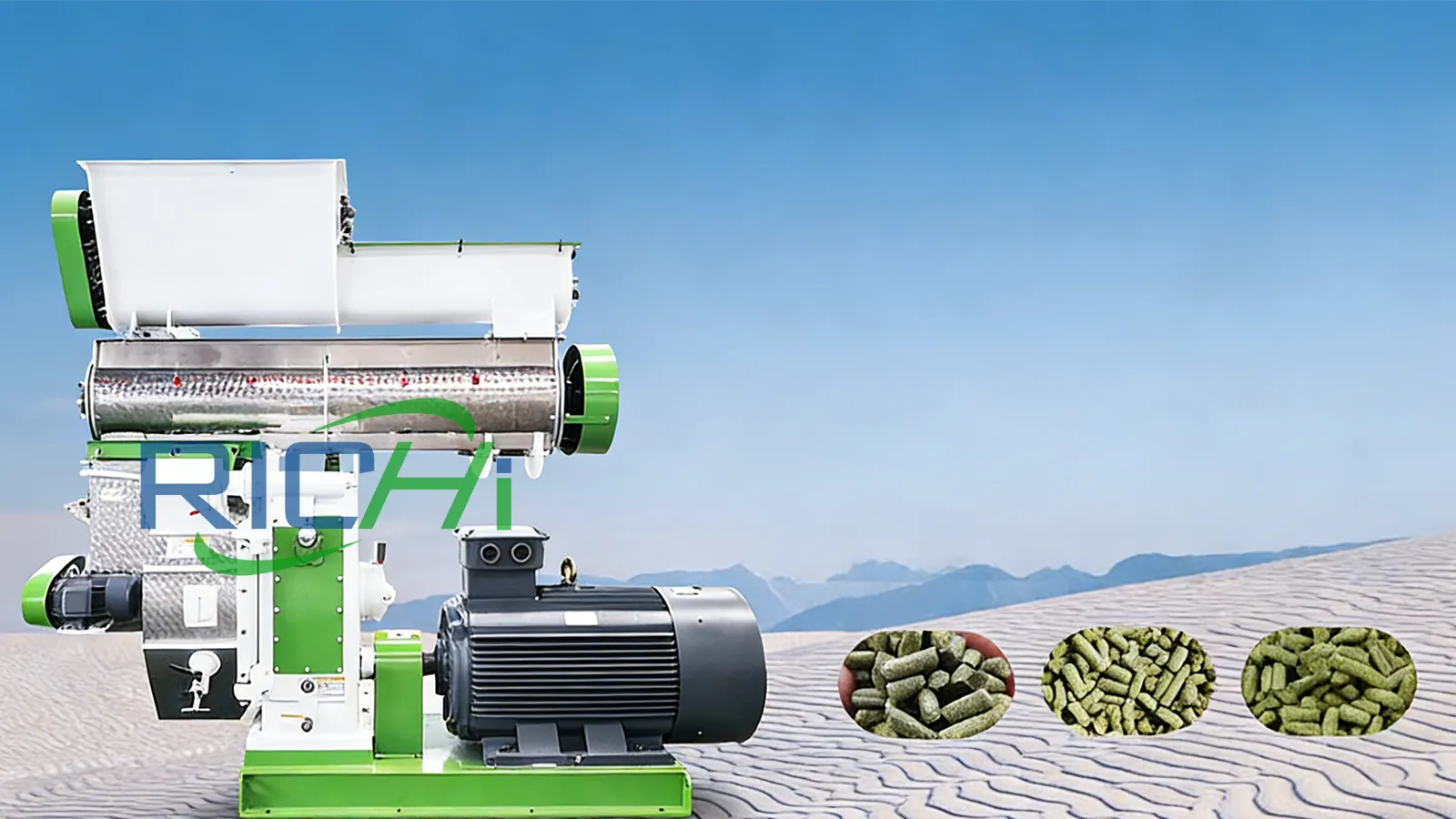

Application Of goat feed pellet making machine

RICHI goat feed pellet making machine is suitable for processing a wide range of raw materials. These include crop-based raw materials, feed additives, binders, flavorings, and other special ingredients.

Commonly used crop-based raw materials include grains (corn, wheat, rice, etc.), legumes (soybeans, peanuts, sunflowers, etc.), fibrous materials (straw, forage grass, etc.), root crops (sweet potatoes, sugar beets, etc.), and by-products of cash crops (date palm residue, palm kernel meal, etc.).

Corn

Wheat

Soybeans

Peanuts

Pumpkin vines

Alfalfa

Sweet potatoes

grass

American customers who purchased our sheep feed pellet making machine add 5% premix to their basic crop ingredients to produce lamb fattening feed, achieving a daily weight gain of 280g; New Zealand customers add 5% fish meal and 5% minerals to their ingredients, resulting in a significant 12% increase in milk production for lactating ewes; Kenyan customers add 5% molasses to make the feed more palatable, and so on.

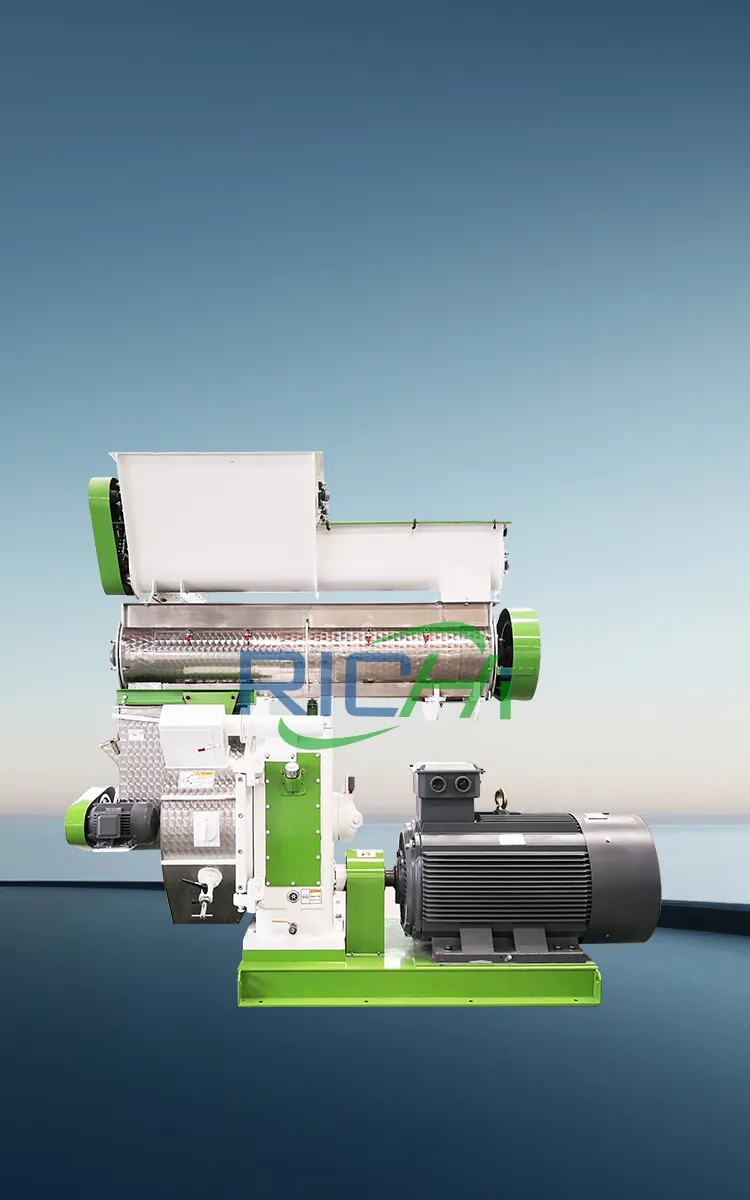

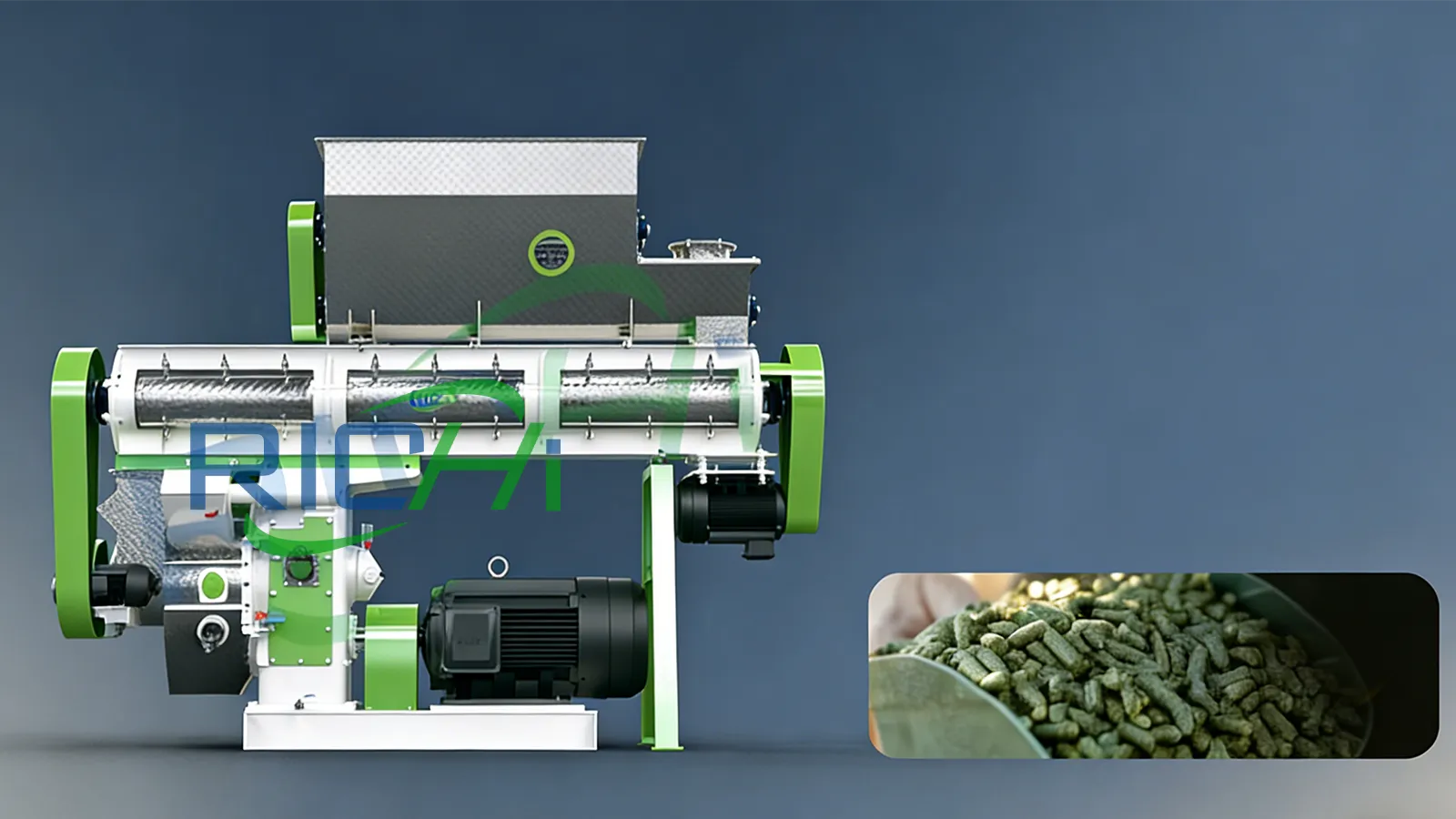

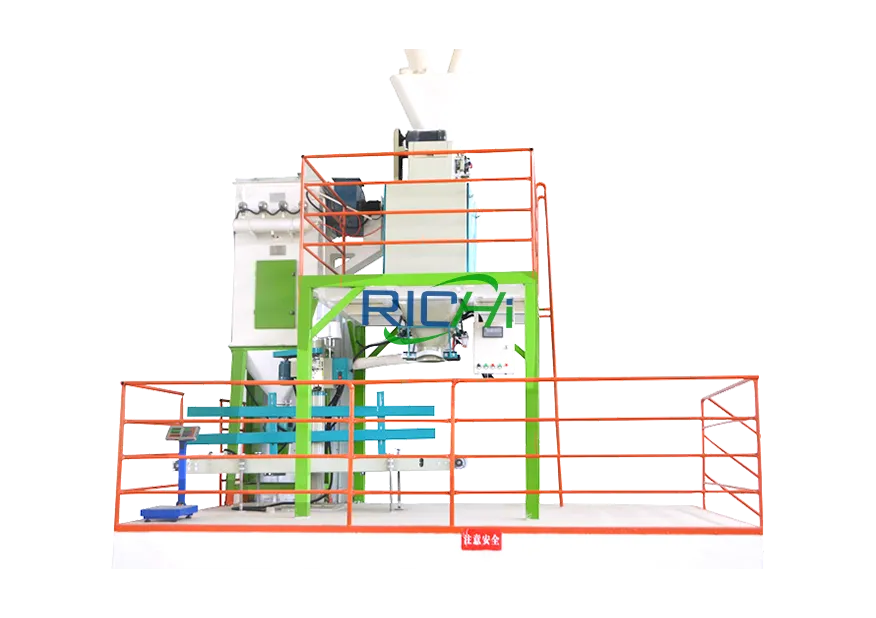

The Structure Composition Of goat pellet machine

Goat feed raw materials contain a large amount of roughage such as peanut vines, soybean stalks, and grass powder. RICHI Machinery has developed a professional goat feed pellet making machine, making the machine structure more suitable for producing goat feed pellets.

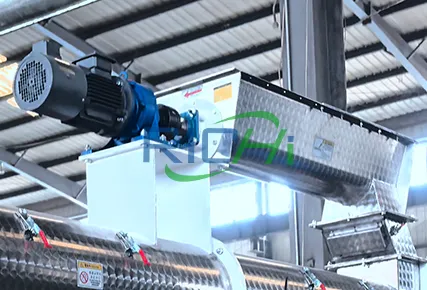

Feeding System

Goat feed raw materials contain relatively high levels of corn, soybean meal, and grass powder, which can easily cause feeding difficulties. The variable frequency feeder, through automatic adjustment, achieves stable and precise material conveying, making the goat feed pelletizing process smoother.

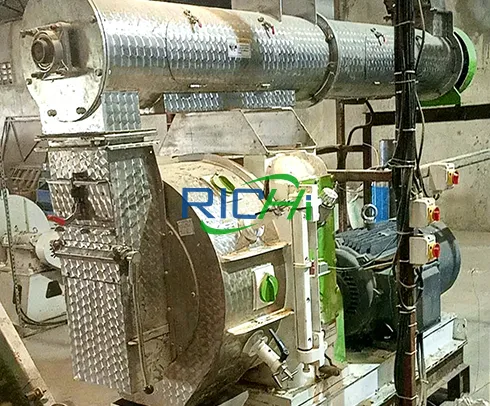

Conditioning System

The conditioning system is usually an indispensable part of goat feed production. Through hydrothermal treatment, it softens the fibers in the raw materials, improving the gelatinization, plasticity, and binding properties of the materials. It also increases moisture content, preventing mold wear.

Forced Feeder

After conditioning at 80-85℃ for 30-90 seconds, the material falling into the chute below can easily form bridges. The forced feeder uses a turbine motor to continuously break up the arches, providing sufficient material for the pelletizing chamber.

Ring Die

Roughage contains silica, which places higher demands on ring die material. Lambs eat 3-4mm pellets, growing goats 4-6mm, breeding bucks 6-8mm, requiring careful selection of ring die aperture. RICHI ring dies use high-chromium alloy and offer varied die hole options.

Pelletizing System

Goats often prefer to push aside softer, easily broken pellets and instead eat the powder and broken pieces. RICHI goat feed pellet mills, through carefully optimized enhanced conditioning and highly durable wear-resistant pressure rollers, ensure higher pellet firmness and lower breakage rates.

Drive System

RICHI goat feed pellet making machines use a three-phase asynchronous motor with a gearbox for efficient transmission. This results in greater torque, more stable operation, and simpler maintenance, fully improving the machine’s impact load capacity and is specifically designed for goat feed production.

Goat Feed Pellet Making Machine Model

Goat feed pellet making machines are widely used by different customers in various production scenarios, and their investment budgets and raw materials vary considerably. Therefore, it’s impossible to meet all customer needs with a single model of pellet mill.

Based on market demand, RICHI has developed pellet mills with various capacities and power ratings, enabling you to find the most suitable core pelletizing equipment for your specific needs.

| Grain-based goat feed pellet machine | ||||||||

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

| Main Motor Power(kW) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power(kW) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Conditioner Power(kW) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring Die Inner Diameter(mM) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellet Diameter(MM) | 2~12 | |||||||

| Capacity(T/H) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

| Forage-Based Goat Feed Pellet Mill | ||||||

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

| Main Motor Power (kW) | 22 | 37 | 90 | 132 | 185 | 250 |

| Arch-Breaking Feeder Power (kW) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power (kW) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter (MM) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished Particle Diameter (MM) | 4~12 | |||||

| Output (T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

Our goat feed pellet making machines are mainly divided into two models: SZLH and CZLH. The main difference between the models is that the SZLH is primarily used for making feed from grain-based raw materials, while the CZLH is specifically designed for processing forage and straw-based raw materials.

The pelletizing process of a goat feed pellet machine

Working Principle

The goat feed pellet making machine primarily utilizes the heat and moisture from a conditioner, combined with the triple pressure action of dual pressure rollers. It physically modifies and restructures materials with low cohesiveness, such as straw and forage.

Ultimately, it sterilizes and softens the raw materials and then rolls them into compact pellets, resulting in a high-quality feed product that promotes rumination and saliva secretion in goats.

Advantages And Features of Goat Feed Pellet Making Machines

RICHI Machinery has developed a dedicated goat feed pellet making machine that transforms low-value, high-fiber agricultural waste into high-standard, high-value commercial feed, allowing you to obtain higher value at a lower cost.

Furthermore, during our 30 years of research and development, our equipment has achieved a maximum service life of 25 years.

High Adaptability

The RICHI goat feed pellet making machine uses a high-compression ratio and a wear-resistant special ring die, quickly easily adapting to high-fiber materials. At the same time, the 40CrMnTi alloy press rollers ensure better molding of fibrous materials and more tighter pellets.

Stable Transmission

Compared with traditional belt drive systems, the RICHI goat feed pellet mill uses a heavy-duty gearbox transmission, making the entire transmission and pelletizing process smoother, more efficient, and quieter. It can also fully meet the high load requirements of processing high-fiber materials.

Ultra-Durable

The entire goat feed pellet machine is constructed with thickened steel and robust welding technology, and the core rotating parts use German SKF brand bearings. In addition, the conditioner uses high-quality 304 stainless steel and integrally forged paddles, easily extending the machine’s service life.

Related cases of goat feed pellet making machines

There are over 300 breeds of goats worldwide, and RICHI goat feed pellet machines are exported to the United States, Argentina, Uzbekistan, France, and other countries, where they are used by customers to produce various types of goat feed.

Goat feed pellet making machine in Argentina

This project started in October 2021, and the entire installation cycle was about exactly 50 days. The feed is mainly purchased by customers who raise Angora goats. The total cost of the complete set of equipment was just $184,500.

- Output (T/H) : 5

- Model : CZLH678

- Pellet size (mm) : 6

goat feed pellet mill in the United States

In this project, our customer uses corn, soybean meal, and premixes as raw materials for production. Currently, the feed produced is mainly used to feed Boer goats, Alpine goats, Saanen goats, etc. We built a complete production line for the customer, with a total cost of $325,000.

- Output (T/H) : 10-12

- Model : SZLH420

- Pellet size (mm) : 4-8

goat feed pellet mill for sale Uzbekistan

The customer is a large local feed producer. When they contacted us, they had a poultry feed production line in their factory. To increase the variety of feed produced, they decided to add another production line for Uzbek Black goat feed. The price of the complete set of equipment was $415,000.

- Output(T/H) : 15

- Model : SZLH508

- Pellet size (mm) : 6-8

goat feed pellet mill for sale New Zealand

Ryegrass, alfalfa meal, and plantain are the core raw materials our customer uses for goat feed pellets. This also significantly increases the requirements for the raw materials processed by the pellet mill. The complete set of equipment we designed for the customer is priced at $85,000.

- Output(T/H) : 4

- Model : CZLH678

- Pellet size (mm) : 6

Goat feed pellet making machine in El Salvador

Goat meat is very popular in El Salvador, but the scale of farming is relatively small. When the customer approached us to design a production line, they requested the production of high-quality Criollo goat feed. The total cost of the entire equipment was $170,000.

- Output (T/H) : 5

- Model : SZLH350

- Pellet size (mm) : 6-10

Goat feed pellet making machine in France

The French customer had their own sheep feed production line. After 8 years of continuous operation, the original line was no longer functional. Based on the customer’s situation, we customized a new sheep feed pellet line, with equipment priced at $320,000.

- Output(T/H) : 10-12

- Model : SZLH420

- Pellet size (mm) : 4-6

Related Videos

RICHI not only manufactures professional pelletizing equipment but can also customize professional goat feed production lines for you. Below are examples of goat feed production lines we designed for clients in Uzbekistan and Argentina.

The Entire Process Of goat feed pellet

The goat feed pellet making machine is the main core equipment for producing goat feed. However, the production of goat feed pellets typically involves several stages: crushing, mixing, pelletizing, cooling, screening, and packaging.

01

Drying

Whether drying with a drying drum is necessary often depends on whether the moisture content of your raw materials is less than 15%. In fact, if your raw materials do not exceed this moisture content, drying is usually not necessary.

02

Crushing

The crushing stage mainly involves crushing corn, cottonseed meal, forage, and straw into smaller pieces. This ensures that the materials can be mixed evenly.

03

Mixing

Goats have high copper requirements, resulting in complex formulations. Grains, vitamins and other materials need even mixing by feed properties. Premix production, in particular, requires extremely high mixing uniformity.

04

Liquid Addition

The main purpose of liquid addition is to improve the energy value, nutritional value, and palatability of the feed. Therefore, the liquids added here generally include soybean oil, molasses, and flavorings.

05

Pelletizing

Carefully formulated materials enter the goat feed pellet machine pelletizing chamber after processing by the variable frequency feeder, conditioner, and forced feeder, then transform into dense, uniformly sized pellets under high temperature and pressure.

06

Cooling

Only after cooling can the pellets be considered finished feed. Cooling not only cools the pellets but also removes excess moisture, effectively preventing mold growth in the finished feed and preventing product quality contamination.

07

Screening

We design vibrating screens and rotary classifiers to perform a final screening of the finished pellets, ensuring that the finished pellets for sale and feeding are uniform in size and of superior quality.

08

Packaging

The final step in the entire feed production process is packaging the qualified materials. In this stage, you can choose to use fully automatic packaging or manual packaging.

The Prospects of the Goat Feed Pellet Manufacturing Industry

The prospects for the goat feed production industry are bright.

With the scaling up and concentration of goat farming, goat breeders are demanding higher quality and nutritional value in finished feed products. This indicates an urgent need for standardized, high-quality goat feed production.

Our goat feed pellet making machine can be used not only to produce goat feed but also ruminant feed for cattle, camels, and other animals.

Prospects for Specialized Goat Feed Factories

There are over 300 different breeds of goats, and even within the same breed, the nutritional needs for pellets vary depending on the growth stage.

Farms and breeders are increasingly looking for feed that provides precise fiber requirements and protein supplementation for their goats.

Based on our experience, it takes approximately 2-5 years for a goat feed factory to recoup its investment. Typically, the specific return on investment time depends on the size of the factory, your cost structure, and the final marketing profits.

Prospects for Goat Farms

With the increasing demand for healthy eating, the demand for lamb meat, wool, goat milk, and related dairy products is constantly growing.

At the same time, the shift from dispersed farming to large-scale, branded production has brought new development models to farms.

Prospects for Ruminant Feed Factories

Goat feed is just one type of ruminant feed, and there is a large global market for cattle and sheep.

In particular, North America and Western Europe have concentrated cattle and sheep farming, leading to a greater focus on the value of specialized feed.

Why Choose RICHI?

RICHI Machinery is an enterprise integrating R&D, design, and manufacturing of pelletizing equipment products, as well as overall project construction. Therefore, we not only produce professional goat feed pellet making machines but also the complete set of equipment required for goat feed production lines.

One-on-One Customization

Different growth stages and breeds of goats lead to vastly distinct and varying requirements for feed pellets. Because of this, RICHI will customize the suitability of the goat feed pellet making machine and the exclusive construction of the goat feed production line precisely according to your needs.

Full-Process Service

From your initial inquiry about goat feed machines and related equipment, RICHI Machinery will work with you every step of the way. Whether it’s equipment production, installation, factory construction, or lifelong technology updates, RICHI will provide you with the most meticulous and patient service.

Extensive Experience

Currently, we have built more than 1,000 feed mills, and our expertise in building goat feed mills is far more detailed and comprehensive. By choosing us, you are not only choosing a single piece of equipment, but also our rich current pelletizing experience and future innovative technologies.

Frequently Asked Questions

The variety of goat breeds and feed formulations may raise many questions for you. The following questions and answers may provide some clarification.

What are the optimal pellet sizes for young and adult goats?

+

The recommended pellet diameter for young goats is 2-4mm, and for adult goats it is 8-10mm. Goats at different growth stages have different pellet requirements, and the following table may provide you with more detailed answers.

| Recommended pellet sizes for goats at different growth stages | ||

| Growth Stage | Required Particle Diameter (mm) | Required Particle Size (mm) |

| Lambs (0-2 months) | 2-4 | 5-10 |

| Young lambs (2-4 months) | 4-6 | 8-15 |

| Growing sheep (4-12 months) | 6-8 | 8-15 |

| Adult sheep (>12 months) | 8-10 | 10-20 |

Can your goat feed pellet making machine process 100% alfalfa?

+

Yes. Our goat feed pellet making machines are mainly divided into two types: one is the SZLH series, designed for grains such as corn, wheat, and beans; the other is the CZLH series, specifically designed for processing forage and alfalfa.

Although our pellet mill can process 100% alfalfa, we do not recommend feeding your goats with only one type of feed, as this can easily lead to nutritional imbalances.

If you are specifically using it to supplement fiber feed for your goats, then it is perfectly suitable.

What is the recommended moisture content of the raw materials before pelletizing with the goat feed pellet making machine?

+

The recommended moisture content is between 15% and 18%. The moisture content of the material in the pelletizing chamber greatly affects the quality of the finished pellets. Ideally, the moisture content should be between 15.5% and 17%, with a minimum of 14% and a maximum of 20%.

Why should I use a goat feed pellet making machine to make feed?

+

The simplest reason to use a goat feed pellet making machine to make feed is that it can bring you greater profits.

Whether you are a goat farm owner or a feed producer, purchasing a goat pellet machine as the core equipment for making goat feed is a necessary choice.

This is due to the picky eating habits of goats; they won’t actively eat stalks, but instead choose the tender leaves. At the same time, goats have a certain herd mentality; when a few goats start eating the new feed, other goats will follow suit. This means that your manufactured feed will have a higher acceptance rate.

If we don’t use a goat feed pellet making machine to make feed, it will result in most of the raw materials not being consumed, and a lot of your costs will be wasted. It will also lead to goats becoming weaker due to picky eating, resulting in poorer nutritional value of their fur and meat, ultimately leading to a decrease in value.

Secondly, if you are a feed producer, a RICHI goat pellet machine can produce goat feed, poultry feed, ruminant feed, etc., simultaneously. However, you need to note that goats require more copper than other animals, so you need to pay attention to this in your raw material formulation. Of course, if your investment budget allows, and you want to produce multiple types of feed, we recommend purchasing two pellet mills for pelletizing different types of feed. You can view other animal feed pellet mills on our website or YouTube channel for more detailed information.

How to maintain a goat feed pellet making machine?

+

You need to perform regular cleaning, timely lubrication, and adjust the position and parameters of the mechanical parts as needed. Furthermore, if you can keep a record of the goat goat feed pellet mill’s operation, you can contact us immediately if any issues arise, and we will contact you within 48 hours.