Animal Feed Production Line

RICHI animal feed production line represents an economically sound investment choice, catering to diverse customer needs for feed pellet production lines.

1-100T/H Animal Feed Production Line Solution

RICHI animal feed production lines offer output capacities ranging from 1 to 100 tons per hour, suitable for manufacturing feed tailored to poultry, livestock, ruminants, and aquatic animals.

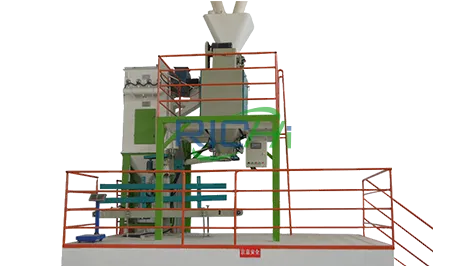

RICHI Animal Feed Production Line

The animal feed production line processes raw materials such as grains, forage, and premix additives from scratch into finished animal feed products that offer high returns, easy management, and convenient transportation.

Animal feed production lines range in price from $20,000 to $5 million and are suitable for various animal feed mills, livestock farms, and upgrades to existing facilities.

Production capacity

(tons/hour)

1-100

Pellet size

(mm)

1-12

Features and Advantages

RICHI animal feed production lines feature highly intelligent control systems, deliver significant energy savings and cost reductions, ensure stable and reliable product quality, and offer robust turnkey customization capabilities.

More Meticulous

RICHI animal feed production lines now include additional standard small equipment, attending to every minor detail of your application.

High Quality

RICHI Machinery specializes in precision equipment manufacturing, dedicated to creating higher-quality production line processes.

High Output

RICHI is dedicated to producing superior animal feed pellets, wholeheartedly supporting your pursuit of high-speed, high-quality output.

One-on-One

RICHI customizes animal feed production lines to your specifications, including equipment color and production line equipment configuration.

Intelligent

RICHI animal feed production lines utilize PLC-controlled batching systems to achieve full automation and enhanced batching accuracy.

Service for all

RICHI design consistently offers truly comprehensive end-to-end services, always ensuring complete worry-free selection and truly worry-free use!

Types of Animal Feed Production Lines

RICHI animal feed production lines can manufacture cattle feed, shrimp feed, chicken feed, sheep feed, pig feed, and rabbit feed. Our feed production lines are designed to process either single-type or multi-type feeds, meeting your diverse feed production needs.

cattle feed

shrimp feed

chicken feed

sheep feed

pig feed

rabbit feed

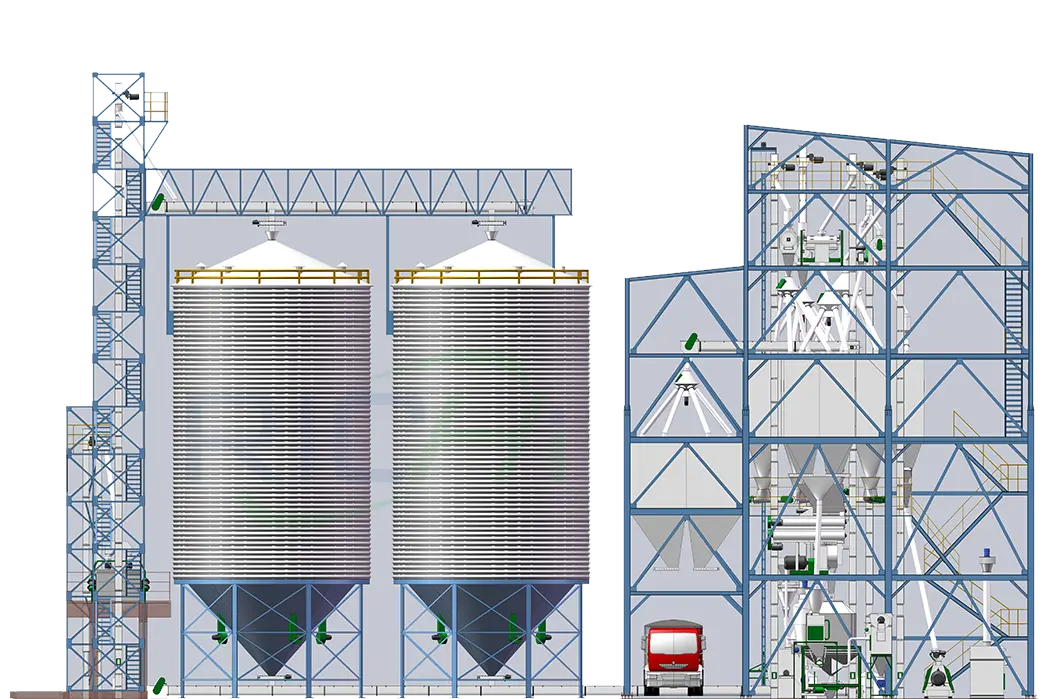

Workflow of Feed pellet Production Line

The animal feed production line consists of six sections: raw grain receiving and cleaning, grinding, ingredient blending, pelletizing, cooling, and screening and packaging.

Raw Grain Receiving and Cleaning Section

01

The raw grain enters the cylindrical primary cleaning screen via screw conveyors and bucket elevators for initial removal of large impurities such as cigarette butts, corn cobs, and stones.

Grinding Section

02

The pre-processed material enters the droplet-type pulverizer through a variable-frequency impeller feeder for pulverization. After processing, it undergoes corresponding cleaning before proceeding to the next stage.

Batching and Mixing Section

03

The mixer connects to the mixing chamber, liquid addition system, and manual feed inlet according to different requirements. Materials enter the mixer through corresponding pipelines for blending and processing.

Pelletizing Section

04

The material undergoes sterilization, disinfection, and conditioning in the conditioning unit before entering the pelleting chamber from the feed hopper. It is then processed into finished feed products through high-temperature, high-pressure pelleting.

Cooling Section

05

Both the top and left sides of the cooler are connected to air locks. Finished feed pellets enter the cooler through the top air lock and are cooled to room temperature by natural airflow.

Screening and Packaging Section

06

Finished feed pellets are filtered through a rotary grading screen and conveyed via pipeline into the packaging silo. They are then bagged and sealed using a dedicated packaging scale, ultimately yielding high-quality animal feed pellets.

Other Notes

07

While the overall workflow of animal feed production lines remains consistent, variations exist in each process due to differences in raw materials, feed output, finished product requirements, plant configuration, and project budgets. Therefore, to ensure your production line delivers maximum operational efficiency, the specific design and implementation plan must be customized one-on-one according to individual needs.

Equipment for animal feed production line

RICHI’s animal feed production line utilizes premium machinery to streamline every production link. Specific equipment details are outlined below:

Weighing System

Equipment for the weighing and metering system includes weighing hoppers, sensors, and weighing instruments.

- Equipment Name:Weighing System

- Capacity :0.5m³

More →

Screw Conveyor

Screw conveyors facilitate material transfer between different equipment and production stages.

- Equipment Name :Screw Conveyor

- Output :10-15m³/H

- Power :2.2KW

More →

Liquid Addition System

The liquid addition system incorporates oils, water, and other liquids during the mixing of solid materials.

- Equipment Name :Liquid Addition System

- Output :50L/Min

- Power :2.2KW

More →

Crusher

The crusher primarily performs initial crushing of raw materials and mixed feed.

- Equipment Name :Crusher

- Capacity :50L/Min

- Power :30KW-110KW

More →

Mixer

The mixer primarily ensures uniform blending of materials to achieve optimal pelletizing results.

- Equipment Name :Mixer

- Output :250 – 2000kg/batch

- Power :4KW-30KW

More →

Pellet machine

The pellet machine is primarily used to roll pre-processed materials into finished feed pellets.

- Equipment Name :Pellet Mill

- Output :1-45 T/H

- Power :22-355KW

More →

Cooler

The cooler primarily cools the extruded feed pellets to achieve greater hardness for optimal packaging.

- Equipment Name :Cooler

- Output :3-5 T/H

- Power :0.75KW

More →

Rotary Grading Screen

The rotary grading screen is primarily used for screening finished pellets before packaging.

- Equipment Name :Rotary Grading Screen

- Output :3-6 T/H

- Power :1.5KW

More →

Packaging System

The fully automatic packaging system is primarily used for bagging and sewing finished feed pellets.

- Equipment Name :Packaging System

- Output :6–8 bags/min

- Power :3KW

More →

Video of animal feed production line

RICHI animal feed production lines are deployed worldwide. Below are five real-world operational case videos showcasing feed pellet production lines in Uzbekistan, Afghanistan, Uganda, Oman, and Indonesia.

animal feed production line projects

Understand the needs of each project customer, serve global customers with high-endquality, and strive to create world-classfeed production solutions.

3-4T/H animal feed production line in Angola

This feed pellet production line is primarily used for manufacturing grass feed. Construction commenced on November 1, 2019, with an installation period of 45 days. The workshop occupies an area of 17,280㎡, and the cost amounted to $150,000.

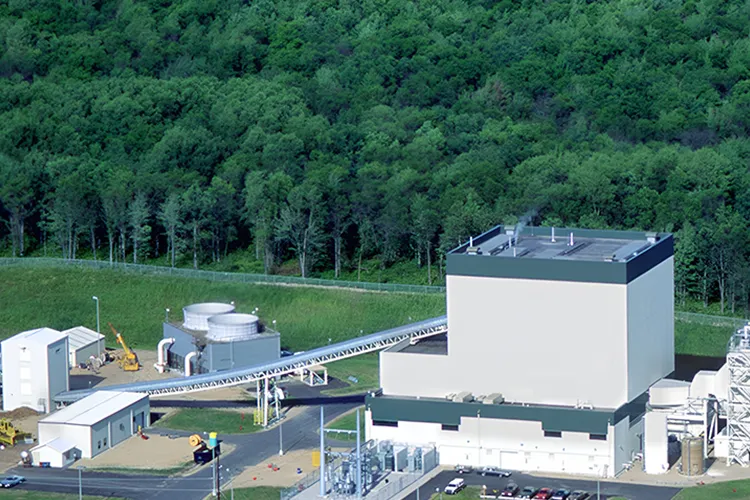

10-12 T/H animal feed production line in the USA

This animal feed pellet production line is primarily used for manufacturing cattle feed with a particle size of 4-8mm. The project commenced construction in May 2019, with an installation period of 40 days and a total construction cost of $380,000.

1-2T/H feed pellet production line in Nigeria

This animal feed production line is primarily used for manufacturing chicken feed with a particle size of 1.2-2.5mm. The project commenced on June 30, 2020, with an installation period of 90 days and a total construction cost of $450,000.

10 t/h animal feed production line in Uzbekistan

This animal feed production line is primarily used for manufacturing shrimp feed with a particle size of 2-4mm. The project commenced on July 1, 2019, with an installation period of 20 days and a total construction cost of $25,000.

5 T/H Feed pellet prodution line In El Salvador

This feed pellet production line is primarily used for manufacturing premixes under fully automated control. The project commenced construction on November 19, 2020, with an installation period of 90 days and a total construction cost of $450,000.

1-2T/H animal feed production line in Ecuador

This animal feed production line is primarily used for manufacturing shrimp feed with a particle size of 1-1.5mm. The project commenced construction on September 3, 2023, with an installation period of 40 days and a total construction cost of $340,000.

30T/H animal feed production line in Vietnam

This animal feed production line is used to manufacture feed for chickens, pigs, and fish, with particle sizes ranging from 2 to 6 mm. The project commenced in June 2020, with an installation period of 60 days and construction cost of $800,000.

3-5T/H animal feed pellet production line In Malaysia

This animal feed pellet production line is primarily used for manufacturing broiler feed with a particle size of 2-4mm. The project commenced on October 29, 2021, with an installation period of 20 days and a total construction cost of $75,000.

2 T/H animal feed production line in Indonesia

This animal feed production line is primarily used for manufacturing shrimp feed with a particle size of 1.2-2.5mm. The project commenced construction on June 2, 2022, with an installation period of 90 days and a total construction cost of $450,000.

RICHI Footprint

NORTH AMERICA

EUROPE

SOUTH AMERICA

AFRICA

ASIA

OCEANIA

RICHI services

RICHI crafts animal feed production lines with meticulous engineering—featuring comprehensive equipment, hassle-free operation, and maximized raw material utilization.

We also provide professional, one-on-one design solutions for animal feed processing plants. Meticulously crafted for your satisfaction!

Brand Commitment

RICHI guarantees that every production line project is personally supervised by technical and installation engineers during setup.

After installation is complete, we provide training for your staff on machinery operation, maintenance, and safety protocols, along with a customized maintenance plan. Our after-sales department conducts regular follow-up calls for maintenance consultation and guidance. We offer a one-year free warranty on equipment (excluding wear parts) and permanent complimentary technical support.

Customized Animal Feed Production Line

How many tons of animal feed production capacity do you require? RICHI animal feed production lines are customized to your capacity needs, ensuring practicality and smooth operation throughout your processing workflow.

about rICHI

RICHI will provide you with comprehensive service support from consultation to after-sales, serving as your most reliable partner throughout the construction and development of your animal feed factory.

Primary Products and Services

Customized design for complete animal feed production line.

enquiry@pelletmakingmachine.com

cattle Animal Feed Production Line

Aquatic Animal Feed Production Line

If you’re unsure about choosing the most suitable equipment, please contact us for detailed consultation.

Why Choose RICH?

RICHI operates its own manufacturing facilities for animal feed production line equipment, meticulously crafting trusted premium brands. Entrusting RICHI with your production line construction means we handle everything from process design, equipment manufacturing, civil engineering guidance, installation and commissioning, personnel training, to the final production of qualified pellets—saving you time, effort, and worry!

RICHI Machinery understands feed and excels in handling diverse raw materials. Our designers develop optimal solutions tailored to specific ingredients, ensuring each process step aligns perfectly with your material characteristics for maximized pelletizing efficiency.

Production Processes Refined to Perfection

RICHI pursues innovation in mechanical design. From our first-generation belt-driven pelletizer to the sixth-generation gearbox direct-drive and intelligent cloud control system, we complete a core upgrade every 18 months. Through innovation, we help you reduce energy consumption, labor, and maintenance costs per ton of feed to industry lows.

Professional and Rigorous Process Design

RICHI prioritizes every design detail and approaches each project launch with utmost diligence. Through meticulous calculations and precise measurements, we ensure maximum data accuracy and feasibility. Dual-redundant systems for weighing, steam, and air supply enable instant failover, guaranteeing efficient animal feed production line operation.

Dedicated Customization Philosophy

RICHI’s ultimate goal is to meet diverse client needs, meticulously crafting the most suitable animal feed pellet production line processes for each customer. Enjoy bespoke services where everything—from equipment to factory layout—is tailored precisely to your requirements, ensuring that every dollar invested truly maximizes output and profitability.

Frequently Asked Questions

Various issues may arise during the procurement and operation of equipment for an animal feed production line. Below are several of the most common problems, which we hope will be helpful to you:

1.What are the specifications of feed pellets produced by RICHI animal feed production line equipment?

+

Our machinery produces pellets ranging from 1mm to 12mm in size:

Chicken feed: 1.5mm–3.5mm

Pig feed: 3mm

Cattle or sheep feed: 4mm, 6mm, 8mm, 10mm

Fish or shrimp feed: 1.5mm

2.Why process raw materials into feed pellets?

+

Single raw materials often fail to meet animals’ nutritional needs across different life stages. Using feed pellet production lines to create pelletized feed ensures balanced nutrition while significantly improving palatability and digestibility.

3.What types of feed can be produced?

+

RICHI animal feed pellet production lines cover multiple feed categories, producing finished pellets for poultry, livestock, ruminants, and aquatic species to meet diverse customer pelleting requirements.

4.What are the main equipment components of a feed pellet production line?

+

Key equipment includes crushers, mixers, pellet mills, coolers, rotary classifiers, and bagging scales.

5.What processes transform raw materials into finished feed pellets?

+

The animal feed production line journey involves: raw material cleaning, crushing, automatic batching and mixing, pelletizing, cooling, screening, and finished product packaging.