Wood Pellet Production Line

The wood pellet production line primarily utilizes forestry biomass resources as raw materials. It processes the feedstock through treatment, processing, and molding, ultimately producing renewable, easy-to-store, and highly combustible wood pellets.

0.5-40T/H Wood Pellet Production Line Solution

RICHI’s wood pellet production line offers 0.5-40t/h solutions to meet the diverse capacity and investment requirements of various customers.

Investment Cost of the Wood Pellet Production Line

The total investment cost for a complete set of complete wood pellet production line equipment typically ranges from $20,000 to $3 million, with specific costs categorized based on the required production capacity.

In addition to purchasing the full set of equipment, factors such as civil engineering costs, water and electricity energy costs, raw material costs, labor costs, construction costs, as well as management and maintenance expenses should be considered during the construction and operation of the wood pellet line.

If you require a detailed investment cost quotation, please contact RICHI for a customized and precise quote.

Production capacity

(tons/hour)

0.5-40

Pellet size

(mm)

2-12

Features and Advantages

RICHI’s wood pellet production line has broken through multiple technological barriers, delivering the most cost-effective pelletizing solutions. It ensures stable and reliable product quality while boasting robust turnkey customization capabilities.

More Advanced

RICHI is dedicated to crafting high-quality machinery, ensuring our wood pellet line features cutting-edge technology and delivers superior manufacturing standards to you.

Better Adapted

RICHI Machinery refines production line details: we replace traditional mechanical conveying with a pneumatic system, making material transport better for lightweight wood-based materials.

Superior Product

RICHI remains fully committed to producing consistently higher-quality finished pellets, delivering premium wood pellets that are more durable, denser, and structurally intact for our customers.

More Economical

RICHI’s wood pellet production line boasts low operating costs and high production efficiency, enabling you to achieve more substantial returns.

More Comprehensive

RICHI manufactures all equipment required for production line construction, providing you with end-to-end production line solutions and services.

More Tailored

RICHI’s team offers equipment configurations based on customer needs, building the optimal customized production line within budget.

Types of Wood Pellet Production Lines

RICHI wood pellet production lines are suitable for log processing plants, sawdust factories, wood chip mills, furniture factories, and wooden pallet plants. Whatever wood material you intend to use, RICHI can meet your processing and production line construction needs.

log wood pellets

sawdust wood pellets

wood chip pellets

Furniture wood pellets

wooden pallet pellets

Workflow of Wood Pellet Production Line

Understanding the workflow of complete wood pellet production line helps clarify the equipment required for building a wood pellet plant.Wood pellet production involves six stages: chipping, crushing, drying, pelleting, cooling and screening, and packaging.

Chipping Stage

01

Raw wood materials are transported via conveyor belts into a drum chipper, where they are chipped into 3 cm to 5 cm thin flakes. These flakes are then conveyed into a water-drop hammer mill through two conveyor belts.

Crushing Stage

02

The chipped materials, after initial chipping and iron removal, are conveyed into a pre-crushing bin via a conveyor belt and then processed in the water-drop hammer mill for further crushing.

Drying Stage

03

Behind the inclined conveyor belt is a pneumatic three-way diverter that sorts materials based on moisture content. Materials that do not meet the required moisture standards are directed into the drying system for processing.

Pelleting Stage

04

After entering the pelleting chamber, the materials undergo dual rolling by two press rollers and are cut with a single cutter, producing pellets with a longer and more uniform granularity.

Cooling and Screening Stage

05

The finished wood pellets enter the cooler through an airlock at the top. Natural cool air enters from the side valves at the bottom of the cooling chamber, carrying away hot air and reducing the pellet temperature to room temperature.

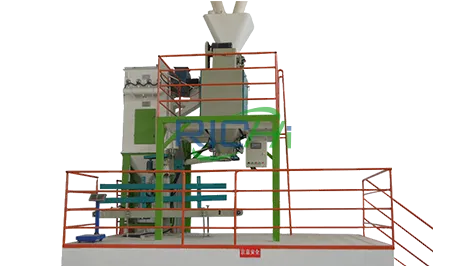

Packaging Stage

06

The finished wood pellets are filtered through a rotary grading screen, conveyed via pipelines into the packaging-ready bin, and finally packaged and sewn using a specialized pellet packaging scale, resulting in high-quality wood pellet products.

Equipment for Wood Pellet Production Line

The combustion resistance of wood pellets ultimately depends on the technical robustness of the production line equipment. RICHI’s fully automated wood pellet production line integrates high-standard machinery throughout every stage—chipping, crushing, drying, pelleting, and cooling—helping you transform challenging raw materials such as logs, wood planks, and wood chips into high-energy, low-dust premium pellets. For detailed equipment lineup, please see below:

Drum Chipper

Mainly used to chip raw materials, primarily logs, into 2–3 cm thin flakes.

- Equipment Name:Drum Chipper

- Power:4 – 45 kW

- Capacity :3 – 5 T/H

More →

Wood Chipper

Primarily used for chipping and crushing small wood blocks and low-volume logs.

- Equipment Name :Wood Chipper

- Capacity :30 – 90 kW

- Power :2.2KW

More →

Template Crusher

Mainly used in production lines that use wood planks as raw material.

- Equipment Name :Template Crusher

- Main Motor Power :75 – 220 kW

- Power :1.1-2.2KW

More →

Screw Conveyor

Primarily used for material transportation between different stages in wood pellet production lines.

- Equipment Name :Screw Conveyor

- Capacity :8–80 m³/h

- Screw Diameter :160–400 mm

More →

Drum Dryer

Mainly used to dry moisture-laden crushed materials to around 15 % moisture content, facilitating better pelleting.

- Equipment Name : Drum Dryer

- Rotation Speed :3 – 12 rpm

More →

Pellet machine

Primarily used to compress wood raw materials through dual-roller pressing and cut them into uniform lengths with a single cutter, producing finished wood pellets.

- Equipment Name :Wood Pellet Machine

- Output :0.5 – 4 T/H

- Power :22-250KW

More →

Cooler

Mainly used to cool the compressed wood pellets, making them harder and more suitable for packaging.

- Equipment Name :Cooler

- Output :1 -40 T/H

- Power :1.5 – 2.2 KW

More →

Rotary Grading Screen

Primarily used for screening pellets before packaging.

- Equipment Name :Rotary Grading Screen

- Output :2 – 50 T/H

- Power :0.18 – 0.55 kW

More →

Packaging Scale & Heat Sealer

Used to weigh finished wood pellets, fill bags, and seal them, ensuring pellet integrity and airtightness.

- Equipment Name :Packaging Scale & Heat Sealer

- Output :2–8 bags/min

More →

video Of Wood Pellet Production Line

The RICHI wood pellet production line can be fully customized one-on-one to meet the specific needs of different clients. Below, we present five production line cases we designed, located in Romania, South Africa, Indonesia, Turkey, and Bangladesh respectively.

Wood Pellet Production Line Projects

Currently, our wood pellet production lines have been exported to over 80 countries worldwide, including the United States, Germany, Poland, Indonesia, Australia, New Zealand, Austria, Mexico, Ecuador, Russia, Kazakhstan, Denmark, Turkey, South Africa, Ghana, Spain, Bulgaria, Serbia, Bangladesh, Uruguay, Argentina, and Brazil. To date, more than 300 wood pellet processing projects worldwide have been constructed with the support of RICHI.

4 T/H Wood Pellet Production Line in Australia

This wood pellet production line uses a mixture of 90% softwood and 10% hardwood as raw materials. It has an annual output of 10,000 tons, a project construction period of 1 month, and a total project cost of USD 430,000.

0.4 T/H complete wood pellet line in Poland

This wood pellet production line utilizes coniferous and broadleaf wood processing waste as raw materials. It has an annual output of 1,000 tons, a project construction period of 1 month, and a total project cost of USD 40,000.

10 T/H Wood Pellet Production Line in Brazil

This wood pellet production line uses pine and eucalyptus as raw materials. It has an annual output of 25,000 tons, a project construction period of 2 months, and a total project cost of USD 630,000.

28 T/H Wood Pellet Production Line in the United States

This wood pellet production line uses lodgepole pine trees killed by pine beetles and forestry processing waste as raw materials. It has an annual output of 70,000 tons, a project construction period of 3 months, and a total project cost of USD 1,150,000.

2-2.5 T/H Wood Pellet Production Line in Germany

This wood pellet production line uses spruce sawdust and wood shavings as raw materials. It has an annual output of 8,000 tons, a project construction period of 1 month, and a total project cost of USD 250,000.

5 T/H complete wood pellet line in Turkey

This wood pellet production line uses pine processing waste and laurel branch residues as raw materials. It has an annual output of 30,000 tons, a project construction period of 2.5 months, and a total project cost of USD 380,000.

8-10 T/H Wood Pellet Line in New Zealand

This wood pellet production line uses radiata pine wood chips and forestry waste as raw materials. It has an annual output of 60,000 tons, a project construction period of 3 months, and a total project cost of USD 650,000.

3-4 T/H Wood Pellet Line in South Africa

This wood pellet production line uses radiata pine wood chips, coffee husks, and sunflower husks as raw materials. It has an annual output of 24,000 tons, a project construction period of 2 months, and a total project cost of USD 320,000.

6-8 T/H complete wood pellet production line in Russia

This wood pellet production line uses pine and birch wood offcuts as raw materials. It has an annual output of 48,000 tons, a project construction period of 3 months, and a total project cost of USD 580,000.

RICHI Footprint

NORTH AMERICA

EUROPE

SOUTH AMERICA

AFRICA

ASIA

OCEANIA

RICHI services

RICHI’s wood pellet production line delivers tailored one-on-one solutions to address your machinery incompatibility issues.

For each complete wood pellet production line project, we assign dedicated professional sales personnel and engineering design teams to conduct comprehensive needs communication with you. This ensures your core requirements are maximally met and provides you with a fully customized optimal solution.

Brand Commitment

RICHI regards quality as the core bridge connecting global customers. Starting from customer satisfaction, we are dedicated to building high-quality, high-standard production lines in every aspect.

RICHI offers full-process services from initial consultation to post-operational maintenance, ensuring you experience the brand’s dedication at every stage and helping you resolve all professional challenges.

Customized Wood Pellet Line

What capacity wood pellet line do you need? RICHI’s wood pellet production lines cover small, medium, large, and extra-large production scales, offering tailored pelletizing solutions for you.

about rICHI

RICHI will continue to break through industry technological barriers and become a strong partner advancing alongside you on your pelletizing journey.

Primary Products and Services

Customized design for complete wood pellet production line.

enquiry@pelletmakingmachine.com

sawdust complete wood pellet production line

Log wood pellet production line

If you’re unsure about choosing the most suitable equipment, please contact us for detailed consultation.

Why Choose RICH?

RICHI operates its own manufacturing facilities for wood pellet production line equipment, meticulously crafting trusted brands. Entrust your production line construction to RICHI for a seamless end-to-end solution—from process design and equipment manufacturing to civil engineering guidance, installation and commissioning, personnel training, and ultimately producing qualified pellets. Save time, effort, and worry!

RICHI Machinery customizes wood pellet production lines, transforming every gram of agricultural and forestry waste into green energy. We offer exclusive one-on-one wood pellet plant construction with turnkey solutions ready for immediate operation. No need to shop around—we help you achieve your green energy goals in one step!

Superior Equipment Stability

RICHI adheres to the principles of safety, stability, and efficiency in equipment manufacturing. With over 27 years of production and installation experience, every piece of equipment in our production line has undergone multiple optimizations by designers. This ensures long-term stable operation, delivering a smoother production experience for you.

Higher Automation Level

RICHI’s wood pellet production line features an intelligent control system with automatic feeding, temperature regulation, and alarm functions. It enables one-button start/stop coverage and single-person night shift inspections, making the line truly low-labor, self-thinking, and self-adjusting. This reduces manual intervention and operational complexity.

Lower Energy Consumption

RICHI equipment holds ISO 9001 and CE certifications, ensuring product quality meets international standards. Specializing in pelletizer R&D processes, our production lines deliver smooth pelletization, higher output, and lower energy consumption during operation. We support clean production practices and align with renewable energy development trends.

Frequently Asked Questions

Complete wood pellet production lines may encounter various issues during overall procurement and operation. Below are several common problems that may be helpful to you:

1.What are the facility requirements for a wood pellet production line?

+

Different production capacities have varying requirements for factory buildings. For instance, a 1T/H capacity requires a floor area of 200 square meters, while a 10T/H capacity is recommended to have a floor area of 1800-2000 square meters. The ceiling height should be at least 8 meters, with an additional 6.5 meters reserved for overhead crane tracks supporting 5-ton capacity.

2.Can my raw materials be processed using RICHI pelletizers?

+

Any biomass organic material can be processed using RICHI equipment. Our systems accommodate diverse raw materials, ensuring reliable and worry-free operation.

3.How much labor does the fully automatic wood pellet production line save?

+

The 1T/H manual production line requires 6 operators per shift, while the Ruiqi fully automated production line requires only 2 operators per shift, saving approximately $38,900 in labor costs annually.

4.What is the construction timeline for a wood pellet production line?

+

Construction includes 25-30 days for equipment manufacturing plus transportation time.

5.How long does it take to recoup investment in a wood pellet plant?

+

The return on investment for wood pellet plants varies based on raw material sourcing channels, production line construction costs and efficiency, and finished pellet sales performance. Taking a 3T/H wood pellet plant in Shandong, China as an example: total investment in equipment, facility rental, and working capital amounts to $231,900 USD. With a net profit of $30.6 USD per ton, annual production capacity reaches 300 days×22 hours×3 tons = 19,800 tons. Annual net profit is $604,200 USD, resulting in a payback period of 4.8 months.

6.What services do you offer besides equipment?

+

Beyond production equipment, we provide clients with comprehensive services including process design, equipment layout planning, factory site planning, post-production commissioning testing, shipping customs clearance, installation training, and after-sales support.