Shrimp Feed Pellet Machine

Application Of Shrimp Feed Pellet Machine

The RICHI shrimp feed pellet machine is suitable for producing specialized feed for various types of shrimp, including Pacific white shrimp, tiger prawns, giant freshwater prawns, redtail shrimp, and brown shrimp.

In addition, it can also produce feed suitable for other animals such as crabs, fish, and turtles, including river crabs, sea crabs, tilapia, catfish, and red-eared sliders.

In addition to being suitable for a wide range of animal species, the shrimp feed making machine can also process various raw materials.

Common ingredients include fish meal, shrimp meal, wheat flour, rice bran, fish oil, and soybean oil. Special ingredients include silkworm pupa powder, hydrolyzed fish, coconut cake, and shrimp head powder.

fish meal

wheat flour

fish oil

soybean oil

pupa powder

hydrolyzed fish

coconut cake

shrimp head powder

Our Indian customers who purchased our prawn feed making machines are using silkworm pupa powder as a raw material to produce higher-value shrimp feed; our Indonesian customers are using coconut cake as one of the raw materials to produce commercial feed for tiger prawns; and our Filipino customers are using 5%-25% shrimp head powder combined with fish meal and squid meal as raw materials to produce feed for Pacific white shrimp, etc.

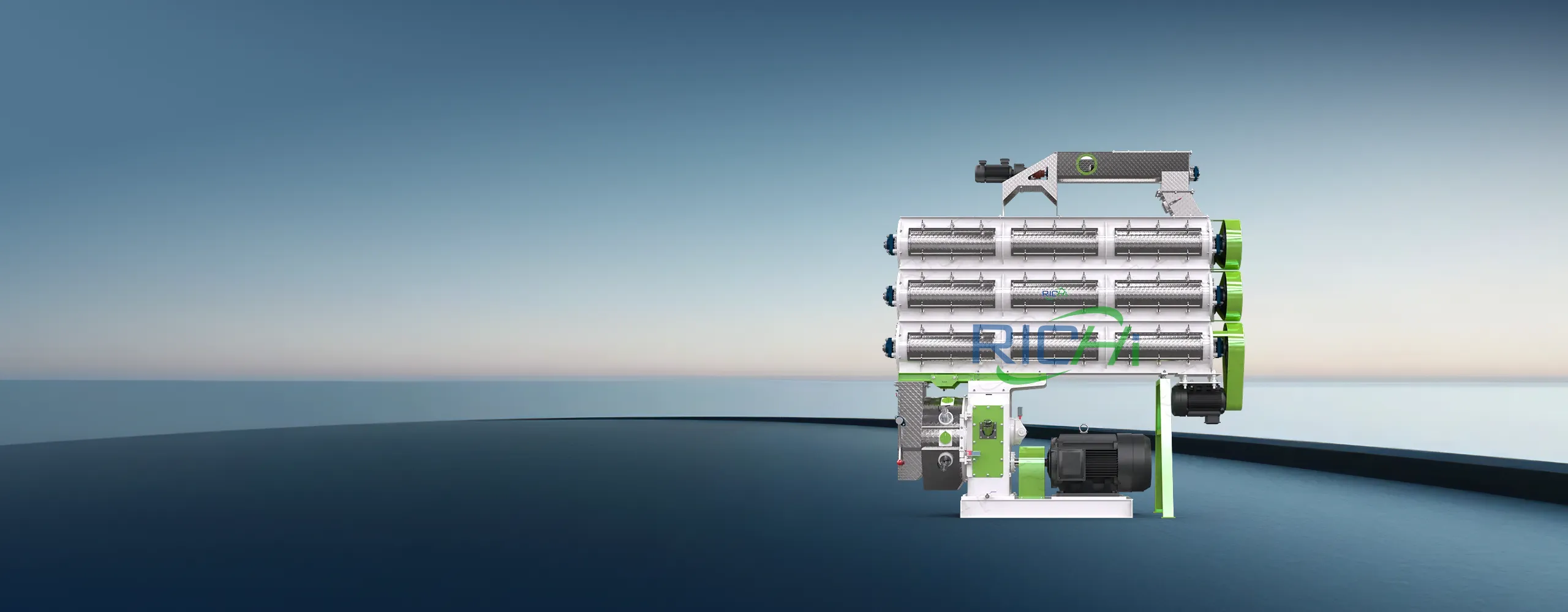

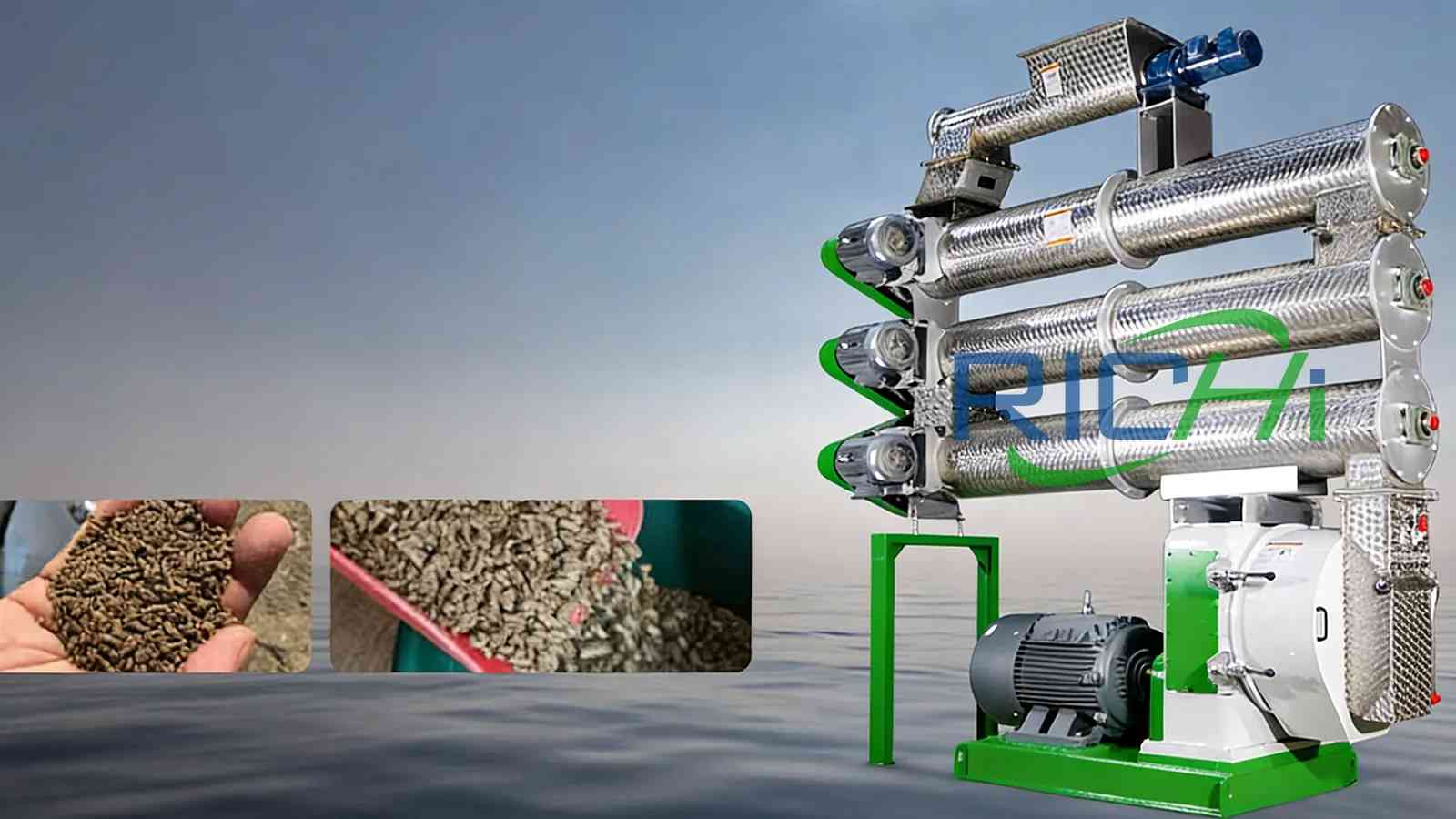

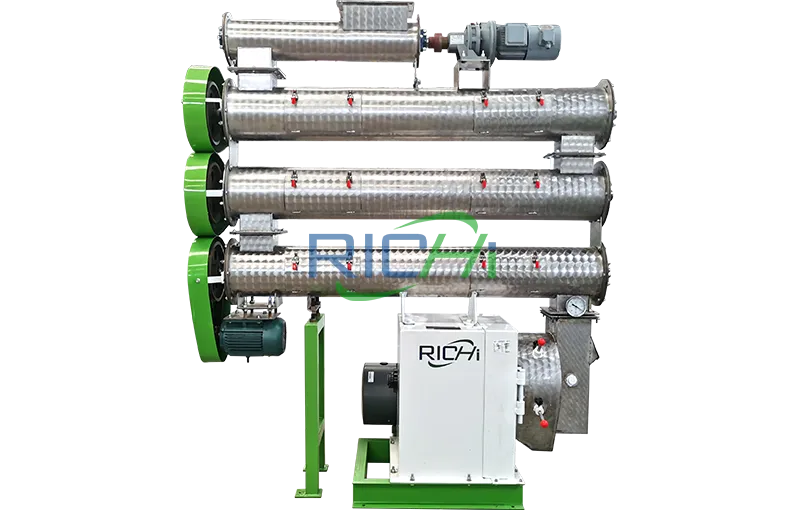

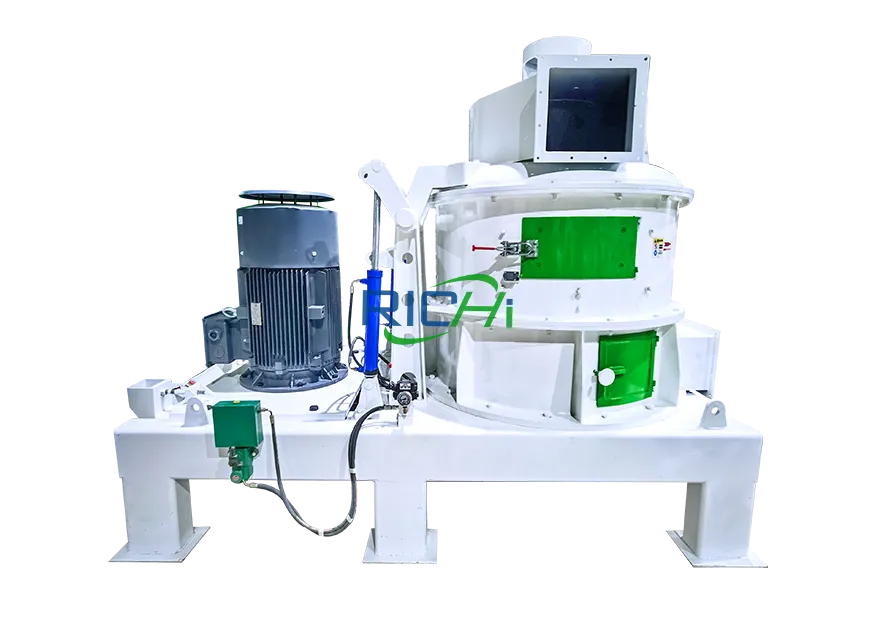

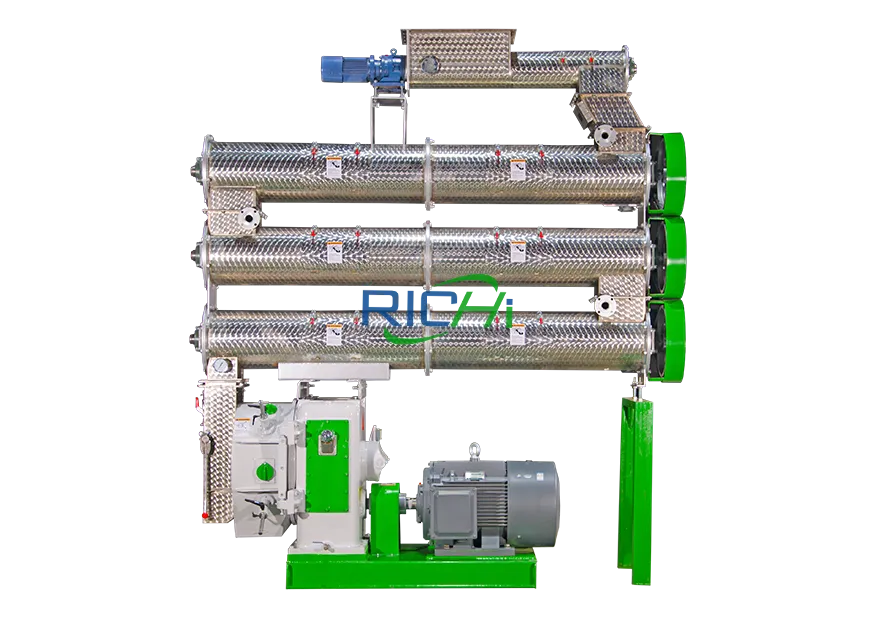

The Structure Composition Of Shrimp Feed Pellet Machine

The quality of the core components of a shrimp feed pellet machine determines the durability and investment value of the machine itself. RICHI has upgraded its core components to address the specific characteristics of shrimp feed production, such as small finished pellet size, difficulty in ring die extrusion, high water resistance, and high degree of gelatinization.

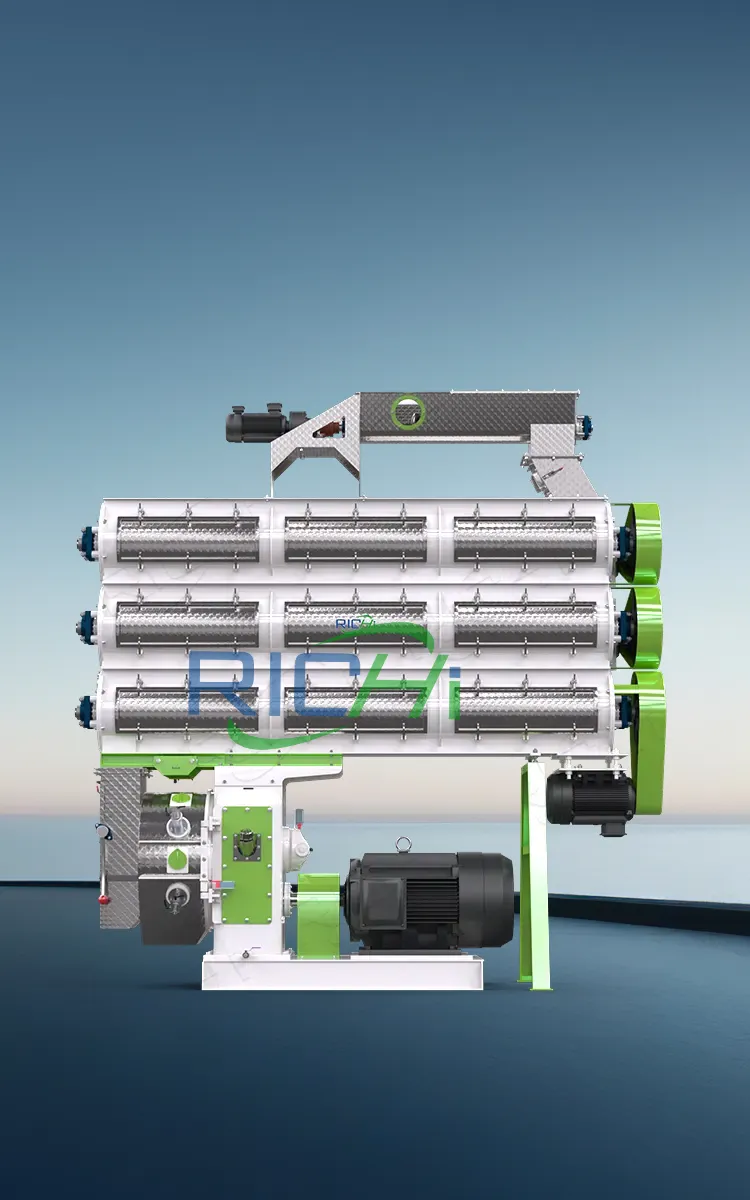

Feeding System

Shrimp feed production faces high material costs and strict protein, amino acid, and vitamin proportion requirements. RICHI equips its pellet machines with variable frequency feeders to ensure high-precision proportioning, continuous operation, and adjustable feeding.

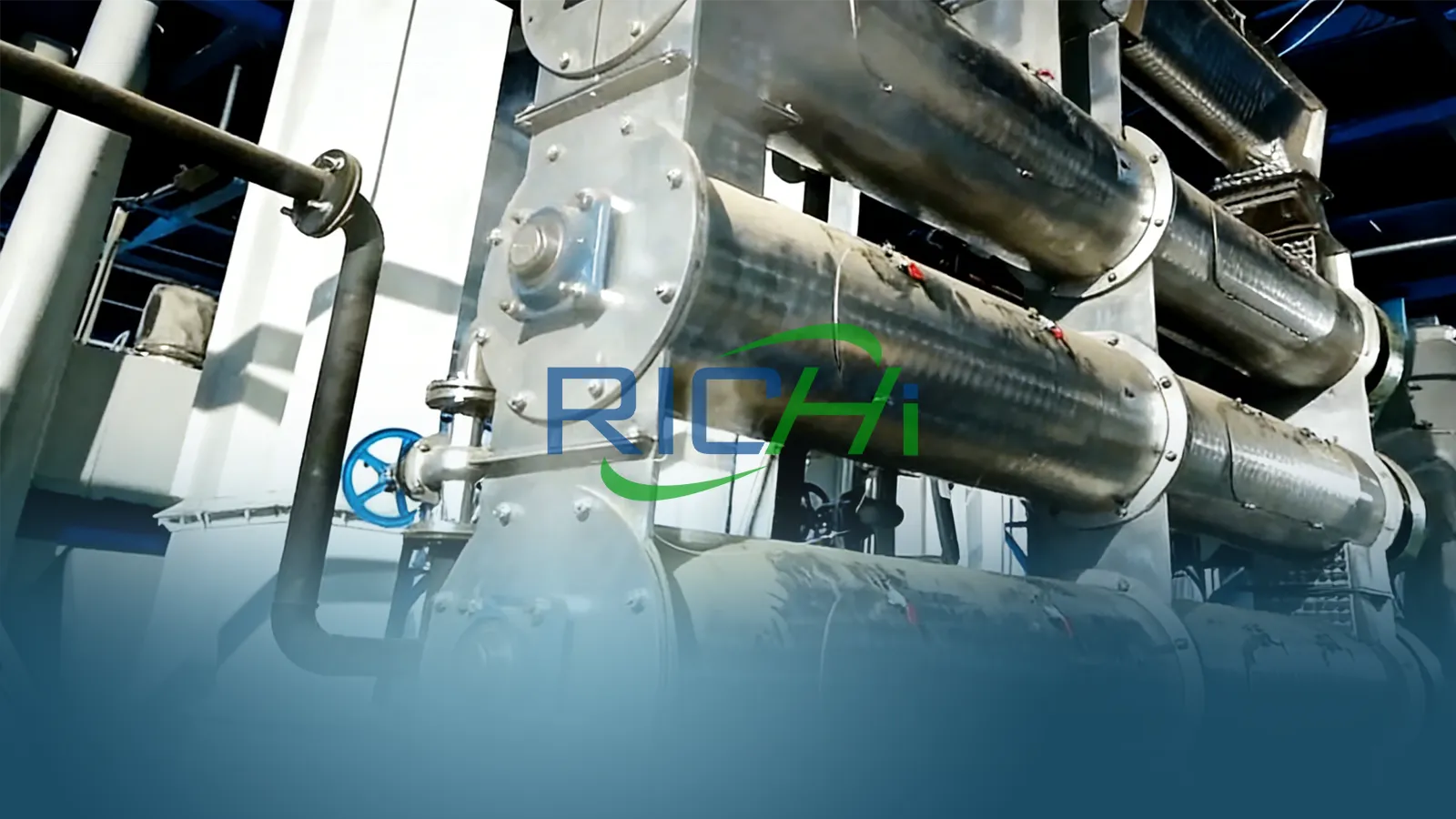

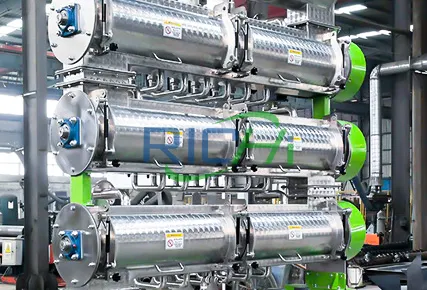

Conditioning System

RICHI shrimp feed pellet machines feature a three-layer conditioner that extends processing time. This enhances material gelatinization for better ring die production and improves maturation to aid shrimp digestion. An additional double-shaft differential conditioner (DDC) is available for higher output requirements.

Ring Die

The particle size of shrimp feed is generally between 1.2-1.8mm, which means the ring die compression ratio of the shrimp feed pellet mill needs to be above 1:20. RICHI uses a ring die compression ratio of 1:20-1:25 to help solve the problems of difficult extrusion and low output.

Pelletizing System

RICHI shrimp feed pellet machines utilize high-quality 304 stainless steel and 40CrMnTi press rollers to combat the significant wear caused by hard materials like calcium, phosphate rock, and crystalline amino acids in feed formulas, thereby extending machine life.

Cutter

Shrimp have small mouths and generally feed by nibbling and segmented eating. The prawn feed machine uses a flat, ultra-thin special cutter, which is more suitable for the production needs of shrimp feed pellets, enabling efficient feeding and reducing waste.

Drive System

Shrimp feed production requires a low rotational speed but high power from the pellet mill. Based on this characteristic, RICHI uses a 6P motor to reduce the pelleting speed and increase the pelleting torque, ensuring higher quality shrimp feed.

Shrimp Feed Pellet Machine Model

When designing and manufacturing shrimp feed pellet machines, RICHI takes into account the specific feeding habits of shrimp, such as their tendency to grasp and gnaw on their food.

We adjust parameters such as the number of conditioner layers, ring die compression ratio, cutter thickness, and main motor power to create prawn feed manufacturing machines that best suit your needs.

| Shrimp Feed Pellet Machine | |||||||||

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 | SZLH858 |

| Main Motor Power(KW) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 | 355 |

| Feeder Power(KW) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 | 2.2 |

| Conditioner Power(KW) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 | 15 |

| Ring Die Inner Diameter(MM) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 | 858 |

| Finished Pellet Diameter(MM) | 1-3 | ||||||||

| Capacity(T/H) | 0.2-0.4 | 0.6-0.8 | 1-1.4 | 1.5-2.5 | 2-3.5 | 3-5 | 4-6 | 5-8 | 5-8.5 |

| Note: The information in the table is for reference only. Our engineers will update the data as needed, and we are committed to developing prawn feed machines that produce pellets with higher gelatinization and better water resistance. Our sales team will confirm specific details with you individually. | |||||||||

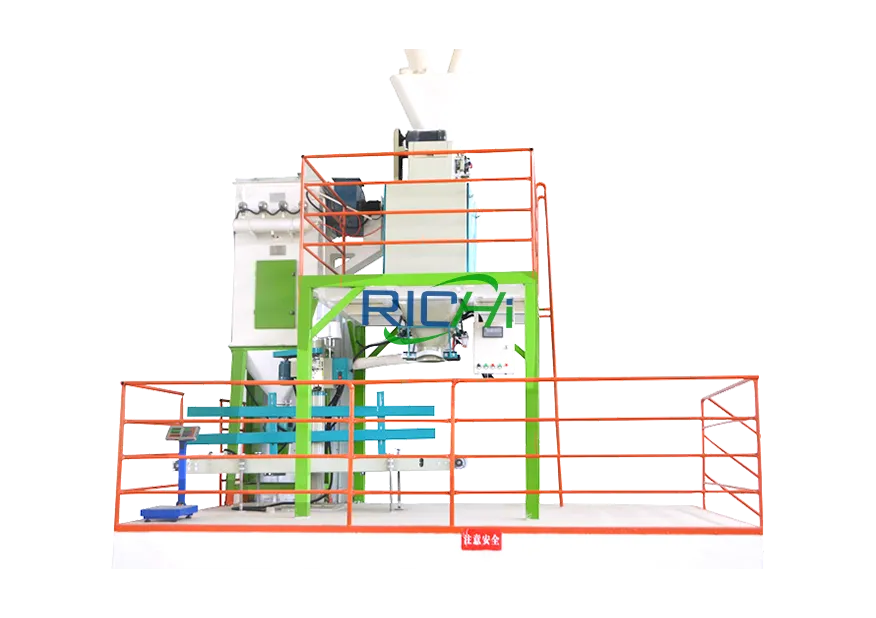

RICHI shrimp feed pellet machine Showcase

Working Principle

A variable-frequency feeder transports the pre-processed fine raw materials to the conditioner.

In the three-layer conditioner, saturated dry steam conditions the materials, enhancing maturation and achieving sterilization.

Subsequently, the paste-like material enters the pelletizing chamber. There, rollers and cutters physically transform it under high temperature, pressure, and shear, ultimately producing standard shrimp feed pellets.

Advantages And Features Of Shrimp Feed Pellet Machines

The quality of a shrimp feed pellet machine determines the qualification, quality, and competitiveness of the finished feed product.

RICHI Machinery’s newly developed shrimp feed pellet mill features a three-layer optional conditioner; thus, it achieves more efficient pelleting, enables smoother production, and delivers higher quality pellets.

High Selectivity

In terms of conditioner configuration, we have designed and manufactured dual-shaft differential conditioners, double-layer extended conditioners, and standard conditioners. These are matched one-on-one to different shrimp feed production requirements, giving you more choices.

Compact Structure

The RICHI shrimp feed pellet machine uses high-precision gear direct drive, quick-release precision clamp ring die compression, and SKF bearings as core components. The entire machine is equipped with a heavy-duty welded base, effectively absorbing vibrations and ensuring a longer service life.

Superior Quality

The shrimp feed produced by this pellet mill not only has higher overall maturation and gelatinization, but also offers better digestibility and water resistance. This means you can easily obtain high-quality feed that is more suitable for shrimp diets.

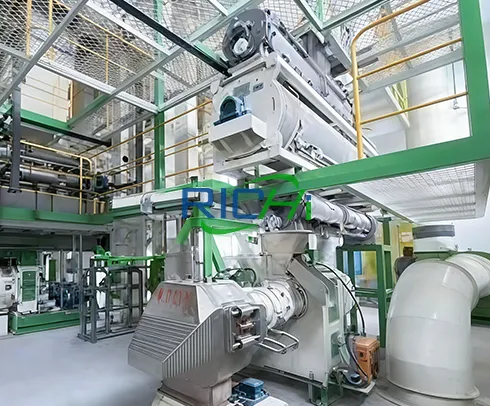

Related cases of Shrimp Feed Pellet Machines

RICHI shrimp feed pellet machines are widely used in shrimp feed factories, aquatic feed factories, turtle feed factories, etc. Currently, our shrimp feed pellet mills are in use in countries such as India, Indonesia, Ecuador, Brazil, Thailand, and Vietnam.

prawn feed machine in Indonesia

This is a shrimp feed production line project that we completed in June 2022. Based on the customer’s raw materials, including fish meal, peanut meal, and flour, we equipped the customer with a complete production line. The price of the entire set of equipment was US$620,000.

- Output(T/H) : 2

- Model : SZLH420

- Pellet size(MM) : 1.5-3

shrimp feed pellet machine in Russia

The customer mainly uses Russian fish meal, sunflower seed meal, and shrimp shell powder as raw materials to produce feed for Pacific white shrimp. Based on the customer’s needs, we equipped them with a production line with an output of 6 tons per hour. The price of the entire set of equipment was US$1,250,000.

- Output(T/H) : 6

- Model : SZLH678

- Pellet size(MM) : 0.8-2

prawn feed making machine in Iran

The customer’s production line requirements are diverse, needing to produce both tiger prawn feed and floating fish feed. Therefore, we equipped the customer with both a shrimp feed pellet mill and a feed extruder. The entire set of equipment is priced at $310,000.

- Output(T/H) : 3

- Model : SZLH508

- Pellet size(MM) : 1.2-2

Shrimp Feed Pellet Machine for sale Ecuador

We began constructing this shrimp feed factory project back in August 2023, and the customer primarily uses squid meal, corn, and Sacha Inchi bean meal as key raw materials. We set the price of the entire set of equipment at US$590,000.

- Output(T/H) : 4

- Model : SZLH558

- Pellet size(MM) : 1.5-2.2

shrimp feed pellet mill in Bangladesh

The customer mainly uses our shrimp feed pellet machine to process raw materials such as mustard oil cake, rice bran, soybean meal, and fish meal to produce shrimp feed suitable for tiger prawns and giant freshwater prawns. The price of the complete set of equipment is US$470,000.

- Output(T/H) : 5

- Model : SZLH678

- Pellet size(MM) : 1-2.5

shrimp feed pellet machine for sale India

This is a shrimp feed mill project we started in May 2022. The customer uses raw materials such as shrimp head meal, squid meal, wheat flour, and rice bran to produce feed for Pacific white shrimp and tiger prawns. The price of the complete set of equipment is US$830,000.

- Output(T/H) : 3-4

- Model : SZLH558

- Pellet size(MM) : 1-2

Related Videos

RICHI’s shrimp feed pellet machines are widely used in the production of high-quality shrimp feed. Furthermore, our shrimp feed production lines have earned excellent feedback from customers. As an illustration, below are feedback videos from our customers in Indonesia and Iran.

The Entire Process Of shrimp feed manufacturing

The shrimp feed pellet machine serves as the core equipment in the shrimp feed production process. Typically, the entire pelletizing process involves seven main steps: crushing, mixing, pelletizing, post-conditioning, cooling, screening, and packaging.

01

Primary Crushing

Raw materials such as fish meal, soybean meal, and wheat flour are initially cleaned and screened before entering a water drop crusher for preliminary crushing.

02

Primary Mixing

During primary mixing, bran and corn flour are precisely combined with small amounts of vitamins, minerals, amino acids, and drug additives to ensure even distribution of these key ingredients.

03

Secondary Crushing

A hammer mill pre-crushes materials, but a dedicated superfine pulverizer is essential to achieve the 80-90 mesh fineness required for shrimp feed pelleting.

04

Screening

Even after ultra-fine crushing, some materials may still be too coarse. Thus, a high-efficiency sieve screens out the unqualified powder for re-crushing.

05

Secondary Mixing

Secondary mixing adds new ingredients or thoroughly blends the primary premix with fish meal, soybean meal, and flour, ensuring even nutrient distribution.

06

Pelletizing

First, crushed material enters a three-layer conditioner for conditioning and gelatinization; then, press rollers in the pelletizing chamber form shrimp feed by high-temperature rolling.

07

Post-ripening

To ensure better shrimp digestion, the feed is often cooked in a post-conditioner. This high-temperature process enhances conditioning, gelatinization, particle density, and water resistance.

08

Cooling

The pellet mill produces shrimp feed that is both hot and humid. Therefore, a cooler is used to naturally lower its temperature, preventing deformation and sticking while also aiding storage.

09

Screening

After cooling, the finished product granules are usually passed through a vibrating screen to remove unqualified fine powder, ensuring the high quality of the shrimp feed.

10

Packaging

This final production step allows you to choose automated packaging systems of various specifications, enhancing the feed’s standardized appearance.

How To Build a Shrimp Feed Mill Plant?

RICHI not only manufactures core pelletizing equipment such as shrimp feed pellet machines, but also has extensive experience in building shrimp feed production lines and shrimp feed factories.

Building an efficient, high-quality, and competitive shrimp feed factory mainly involves four steps:

Research and Budgeting

01

To establish a shrimp feed factory, you need to conduct market research in the local area or at the proposed factory site, analyzing factors such as farming scale, price ranges, and farmer needs.

Secondly, you need to make a reasonable estimate of your investment capital.

Factory Design

02

Factory design is a highly professional engineering project, requiring consultation and planning with a professional feed engineering company.

This also includes the procurement and layout of equipment for the shrimp feed production line.

If you can find an engineering company that integrates equipment manufacturing and factory construction, it will be much more efficient. RICHI meets all these requirements.

Factory Construction

03

Once you reach an agreement with the feed engineering company, they will proceed with the factory construction.

This includes civil engineering, equipment installation, and the detailed construction of the factory building, office area, and marketing area.

Production and Operation

04

After the shrimp feed factory is completed, and after trial production and formula optimization, it can begin formal production and operation.

In this stage, you need to establish your own sales network and provide relevant technical personnel to regularly train farmers on proper usage.

Why Choose RICHI?

From being able to produce pellets to producing the right pellets, RICHI Machinery has been meticulously crafting shrimp feed pellet machines for 30 years, becoming one of the leading manufacturers in the global and Chinese aquatic feed pellet mill market.

High Quality

From the selection of materials for the shrimp feed pellet machine to the refinement of core component processes, RICHI leaves no detail overlooked, creating economical and high-quality pellet mills for you.

Excellent Service

With 30 years of industry experience, RICHI sells its pelletizing equipment to over 140 countries and regions. Furthermore, the company has successfully built and completed over 1,000 feed engineering projects worldwide.

High Efficiency

The pellet machine’s high-temperature conditioning and efficient gear transmission streamline pelleting. Moreover, its integrated ultra-fine pulverizer enhances particle fineness, directly improving pellet quality and your economic return.

Frequently Asked Questions

In today’s complex information landscape, how can you find a suitable shrimp feed pellet machine from a reputable company, or even establish your own shrimp feed factory? This is a question many customers have. The following questions may provide you with answers.

How to determine if a shrimp feed pellet machine manufacturer is suitable?

+

After finding a shrimp feed pellet machine manufacturer, you need to inquire about specific process parameters, request a list of core components, and ask for a configuration table of key parts. Secondly, you need to discuss with them when you can visit their production facility to ensure authenticity and reliability.

RICHI will ensure the credibility of the information for you at the first opportunity and arrange a factory visit time. For more detailed videos, you can visit YouTube.

How to determine if the shrimp feed pellet machine you purchased is suitable?

+

First, you need to assess the core performance of the machine. Check if the pulverization rate of the finished pellets is less than 5%, and whether the finished pellets, when placed in room temperature water, can maintain their shape without disintegrating for 2-4 hours.

Secondly, you need to check the process indicators. For example, the gelatinization degree, cooking degree, and the authenticity of the production capacity of the shrimp feed.

Why use a shrimp feed pellet machine for feed production? Can a feed extruder machine be used?

+

Using a prawn feed manufacturing machine to produce shrimp feed provides shrimp with more palatable, nutritious, stable, and safe feed. It meets the feeding habits of shrimp, avoids water pollution, and maximizes production efficiency.

Shrimp feed can be produced using a feed extruder machine, but it is not recommended.

Firstly, using an extruder to produce shrimp feed significantly increases economic costs. Secondly, shrimp feed produced by an extruder cannot solve the problem of high digestibility, leading to water pollution and discomfort for the shrimp.

Additionally, if you want to understand the difference between shrimp feed pelletizers and ordinary pelletizers, you can visit the animal feed pellet machine section for more information.

Which customers are suitable for RICHI shrimp feed pellet machines?

+

RICHI shrimp feed pellet mills are suitable for customers who pursue stable quality, large-scale production, and long-term return on investment in shrimp feed products. This includes, but is not limited to, professional shrimp feed manufacturers, comprehensive aquatic feed factories, and large integrated aquaculture groups.

What is the price of your shrimp feed pellet machine?

+

The price of RICHI prawn feed machines ranges from $7,000 to $100,000, with the specific price depending mainly on factors such as the machine’s production capacity.

Additionally, if you require a complete shrimp feed production line, the price will increase due to the different matching equipment needed. For specific details, please consult with our sales team and professional engineers.