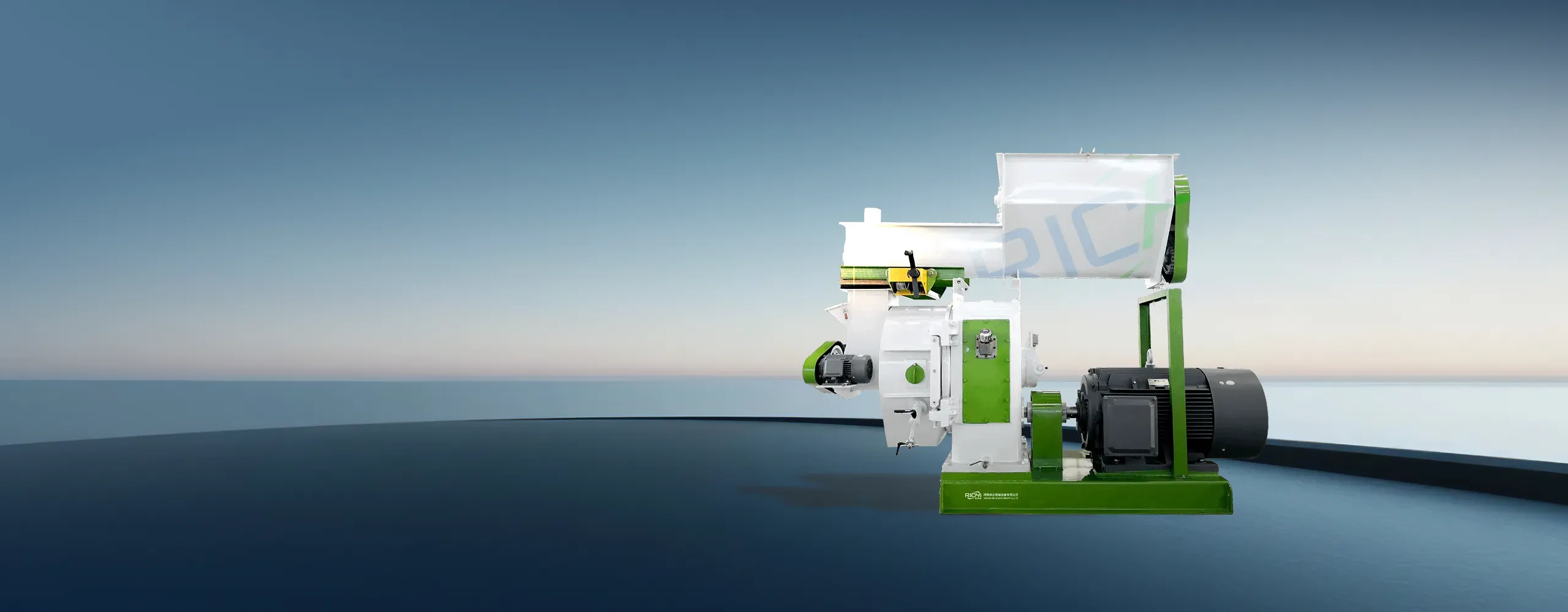

Rice Husk Pellet Machine

The structure composition of Rice Husk Pellet Machine

The rice husk pellet machine features an integral design, comprising a variable-frequency feeder, a feed chute, a forced feeder, a pelletizing chamber, a cutter, and a Siemens motor.

A detailed diagram of the rice husk pellet making machine components is provided below:

variable-frequency feeder

feed chute

forced feeder

pelletizing chamber

cutter

Siemens motor

The RICHI paddy husk pellet machine integrates premium materials, precision engineering, and an intelligent control system. This synergy creates an optimal pelletizing solution specifically engineered for rice husk processing.

Rice Husk Pellet Machine Model

To address the characteristics of rice husks—being lightweight and having poor flowability—the RICHI rice husk pellet mill offers multiple capacity models, providing you with greater choice diversity.

| Rice Husk Pellet Machine | ||||||

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Main Motor Power (KW) | 22 | 37 | 90 | 132 | 185 | 250 |

| Arch-Breaking Feeder Power (kW) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power (kW) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Inner diameter of ring mold (mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished Particle Diameter (mm) | 4~12 | |||||

| Output(T/H) | 0.2-0.3 | 0.3-0.5 | 1.0-1.2 | 1.5-2.0 | 2.5-3.0 | 3.0-4.0 |

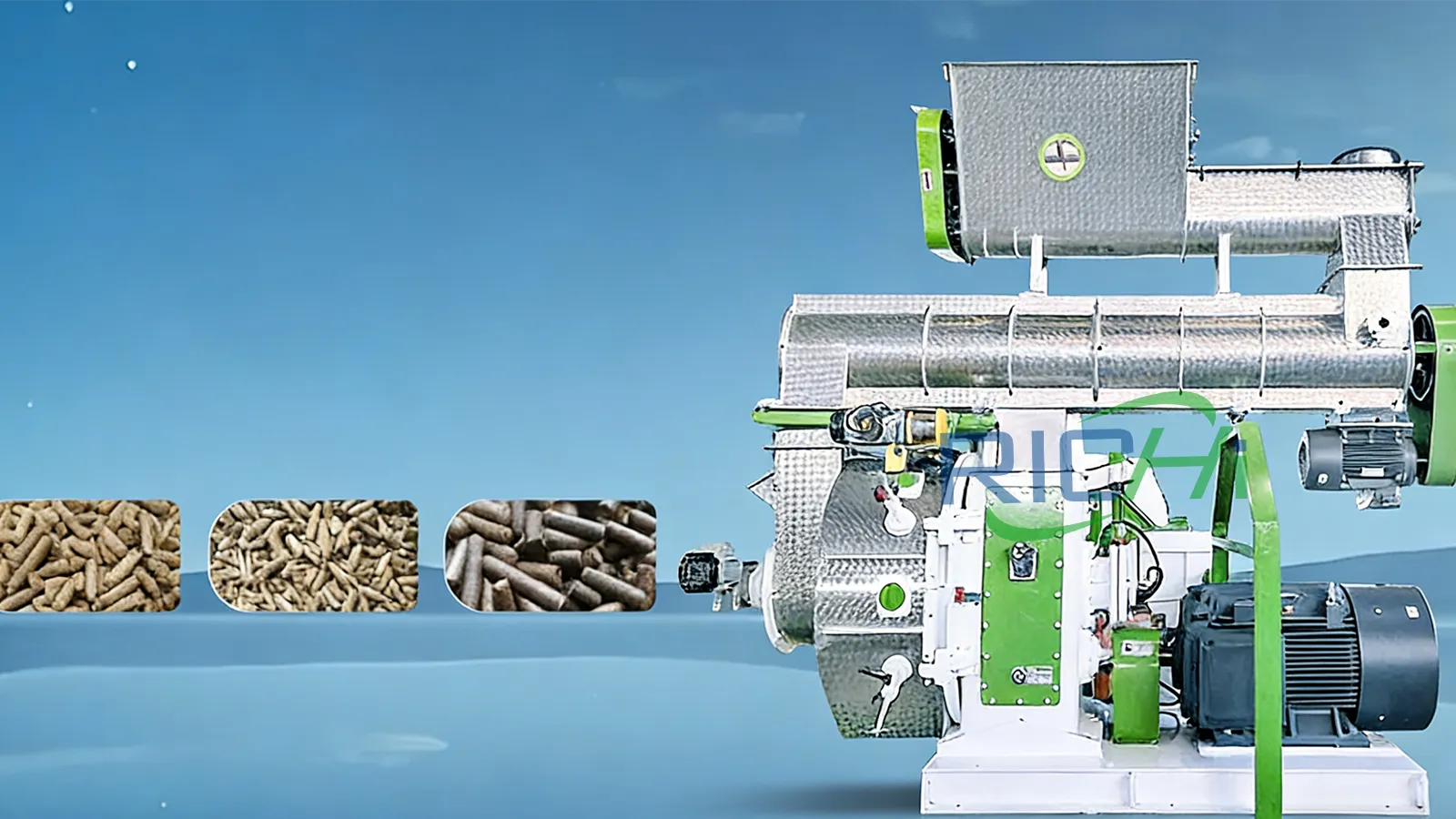

Test Run Video of Rice Husk Pellet mill

Working Principle

The rice husk pellet machine primarily utilizes physical compression, relying on high pressure and high-temperature conditions to form the final pellets.

Pre-processed rice husks are first conveyed through a variable-frequency feeder and a feed chute, then pushed into the pelletizing chamber by a forced feeder. Within the chamber, the material self-bonds under high pressure and frictional heat generated by dual roller compression.

Key Technology Of Rice Husk Pellet Machine

Variable-Frequency Feeder — Ideal for Rice Husk Raw Material

Rice husk features low density and high fluidity, often leading to clogging due to accumulation before pelleting and difficulty in precise feed control at the inlet.

The RICHI paddy rice husk pellet making machine incorporates a wide inlet structure paired with a Siemens variable-speed motor. By automatically adjusting the feed rate through inductive load voltage, it achieves precise control over lightweight rice husk feeding while effectively preventing clogging and caking.

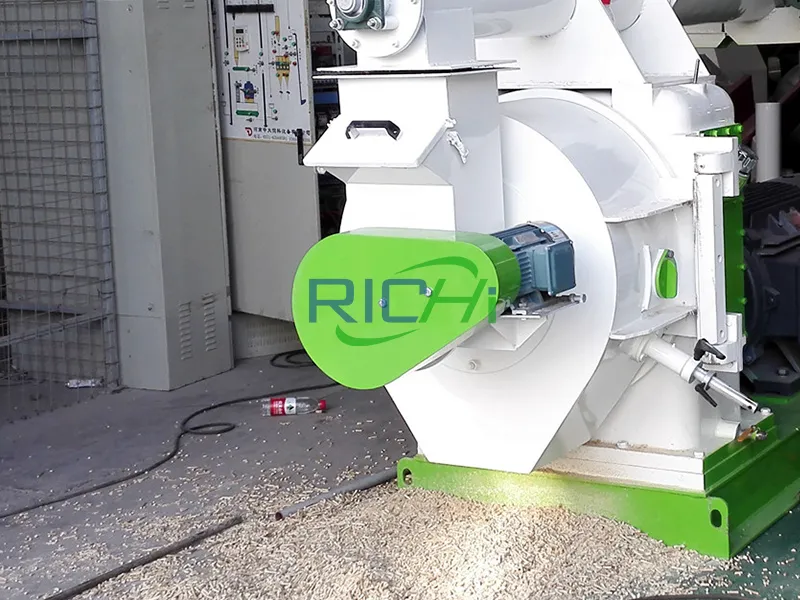

Forced Feeder — Smooth Material Pushing for Effortless Pelleting

When rice husk enters the pelleting chamber via the vertical feed chute, its light weight often causes incomplete entry, accumulation, and bridging.

The RICHI paddy husk pellet machine employs a forced feeder to promptly push materials into the pelleting chamber, reducing issues such as blockage, bridging, and arching for smoother feeding.

42CrMo Pressure Roller — Enhanced Pellet Density

The gourd-like flaky structure of rice husk makes it resistant to deformation during compression, resulting in large inter-particle gaps and high wear.

The RICHI rice husk pellet machine utilizes 42CrMo steel pressure rollers. Replacing conventional materials with this alloy steel offers higher wear resistance and enhanced rolling performance, producing denser, better-formed finished pellets.

Features and Advantages of rice husk pellet machines

High Compatibility

The RICHI paddy husk pellet machine can process rice husk individually and perform mixed pelleting with wood and other biomass materials, delivering superior feedstock adaptability through its flexible material handling design.

Rapid Operation

The RICHI rice husk pellet machine features full-process optimization from feed inlet to pelletizing chamber, ensuring faster operation and higher efficiency via an enlarged feed port, variable-frequency feeding system, and high-quality pressure rollers.

High Forming Rate

The RICHI paddy rice husk pellet making machine achieves a 98% first-pass pellet qualification rate through targeted technical improvements, overcoming rice husk’s poor plasticity with low powder output and high pellet density.

Related cases of rice husk pellet machines

RICHI rice husk pellet machines have been sold worldwide and are used for producing feed, biomass fuel, and organic fertilizer. Below are six real-world case studies from different countries.

2-2.5 T/H paddy rice husk Pellet Machine in Germany

This project uses sawdust, softwood, hardwood, and rice husks as raw materials to produce biomass fuel pellets, replacing conventional fuels.

- Output (t/h): 2-2.5

- Power (kw): 185

- Pellet Diameter (mm): 4

5 T/H Husk Pellet Machine in Kazakhstan

This project primarily uses sunflower seed hulls and rice husks as raw material to produce feed pellets for cattle and sheep, supplementing their nutritional needs.

- Output (t/h):2.5

- Power (kw):185 × 2

- Pellet Diameter (mm): 6

10 T/H rice husk pellet making machine in the USA

This project primarily uses corn stalks, wheat stalks and rice husks as raw materials to produce renewable biomass fuel exclusively for local sales.

- Output (t/h): 10

- Power (kw): 250 × 4

- Pellet Diameter (mm): 8

1-1.5 T/H paddy husk Pellet Machine in Indonesia

This project uses palm kernel shells, wood chips, and rice husks as its primary raw materials to produce clean biomass fuel mainly for local heating.

- Output (t/h): 1-1.5

- Power (kw): 132

- Pellet Diameter (mm): 4

2-2.5 T/H Rice Husk Pellet Machine in Romania

This project uses acacia wood shavings and rice husks as raw materials to produce biomass fuel, replacing conventional fuels for heat generation.

- Output (t/h): 2-2.5

- Power (kw): 185

- Pellet Diameter (mm): 6

1-1.5 T/H Husk Pellet Machine in Lebanon

This project utilizes olive pomace, citrus peels, corn cobs, wheat stalks, poultry manure and rice husks as primary raw materials to produce organic fertilizer for soil enrichment.

- Output (t/h): 1-1.5

- Power (kw): 132

- Pellet Diameter (mm): 4-6

Related Videos

Below are feed pellets based on sunflower seed hulls and rice husks in Kazakhstan, biomass pellets based on wood chips and rice husks in Romania, and organic fertilizer based on poultry manure and rice husks in South Africa.

The entire Process of Rice Husk Pellet Production

The rice husk pellet machine is a key component—but not the entirety—of rice husk pellet production. The entire pelleting process is continuous and can be broken down into the following seven stages:

Raw Material Cleaning & Sifting

01

This stage primarily removes impurities and foreign matter from the raw feedstock, ensuring higher purity of the material and protecting the pellet machine from potential damage.

Drying

02

The natural moisture content of rice husk is typically 80%–90%, while the required moisture level for pelleting is only 12%–13%. Therefore, the material must undergo drying treatment.

Crushing

03

To allow the pellet machine to efficiently press high-quality finished pellets, the raw material needs to be crushed into fine powder. This step is generally required for non-pure rice husk feedstock.

Mixing

04

The raw material for the pellet machine can be either pure rice husk or a mixture of multiple materials (including rice husk). To ensure the uniformity of finished pellets, a mixer is used to homogenize the different raw materials.

Pelletizing

05

After receiving the prepared material, the rice husk pellet machine uses dual pressure rollers inside the pelletizing chamber to press the rice husk powder into finished pellets.

Cooling & Sifting

06

The pellets produced by the rice husk pellet making machine are at a high temperature and are not suitable for immediate packaging. They must be cooled using a cooler, and after cooling, any unqualified fine particles are sifted out.

Packaging

07

The cooled and sifted finished pellets enter the packaging hopper, where an automated packaging system performs weighing, filling, and sealing.

Why Choose RICHI?

RICHI Machinery — your trusted partner, from a single pellet machine to a complete pellet plant, delivering professional expertise to clients worldwide.

Broad Production Scale

RICHI rice husk pellet making machines offer an excellent output range of 0.2–4 T/H, enabling us to provide small, medium, large, and extra-large rice husk pellet production plants. This allows you to easily select the ideal production scale that best fits your specific needs.

Customization

RICHI husk pellet machines can be tailored to your specific requirements—whether for a single unit, a complete production line, or based on your budget. You can compare multiple solutions before finalizing your choice, ensuring the pellet machine is perfectly suited to your needs.

Extensive Experience

RICHI Machinery integrates R&D, manufacturing, sales, and service, accumulating over 30 years of industry experience. We truly prioritize our customers’ perspectives, delivering rice husk pellet machines that are more convenient, efficient, and cost-effective.

Frequently Asked Questions

Selecting the right rice husk pellet machine is no easy task, and you may encounter many questions along the way. Here, we address some common concerns to help guide your decision-making.

The silicon content in rice husks is as high as 15–20%. How quickly does the die of a rice husk pellet making machine wear out, and how can its service life be extended?

+

The high silicon content in rice husks does accelerate wear. The service life of a standard die is approximately 300–500 hours. RICHI uses 40CrMnTi alloy steel ring dies, which undergo carburizing heat treatment. This extends their service life by 2–3 times compared to ordinary dies. To further extend the die’s service life, we recommend regularly flipping the die to utilize both sides and maintaining raw material cleanliness to avoid accelerated wear caused by sand and stones.

The density of rice husks is only 120 kg/m³. How do you ensure stable feeding without material scattering or clogging?

+

The RICHI rice husk pellet machine is equipped with a variable-frequency feeder and a forced feeder. Through frequency conversion regulation and mechanical screw-driven active pushing, feeding stability is enhanced, and issues such as bridging and material scattering are eliminated.

How does your rice husk pellet machine address the challenges of poor plasticity, low forming rate, and fragile pellets associated with rice husks?

+

Our rice husk pellet making machine operates in a high-temperature and high-pressure environment and utilizes alloy steel pressure rollers. This makes the rice husks easier to shape, increases the forming rate, and reduces the amount of broken pellets. Additionally, RICHI Machinery offers free raw material testing. You can send us your material for testing, providing you with greater peace of mind.

The pelleting process generates significant heat. Will prolonged operation cause damage to the transmission gears and bearings of the rice husk pellet machine?

+

Damage to transmission gears and bearings in rice husk pellet making machines is typically caused by poor heat dissipation in the pelleting chamber of traditional horizontal ring-die machines. The RICHI rice husk pellet machine adopts a vertical feeding structure, which effectively controls the operating temperature inside the gearbox to below 80°C. Furthermore, it uses SKF heavy-duty bearings and synthetic high-temperature resistant lubricating oil, ensuring a transmission system service life of 8,000–10,000 hours even under 24-hour continuous operation.

Is the rated capacity a theoretical value or an actual value? Can the rice husk pellet machine achieve this capacity when using rice husks as the raw material?

+

RICHI’s rated capacity is based on actual measured values. Taking the MZLH420 model as an example, its rice husk processing capacity is 1.0–1.2 tons per hour, based on continuous operation tests with a moisture content of 12–15% and a particle size of 3–5 mm. Actual output may vary by 5–15%, but RICHI offers free sample testing and specifies acceptance criteria in the contract: if the actual capacity falls more than 10% below the rated value, we will take responsibility for rectification.