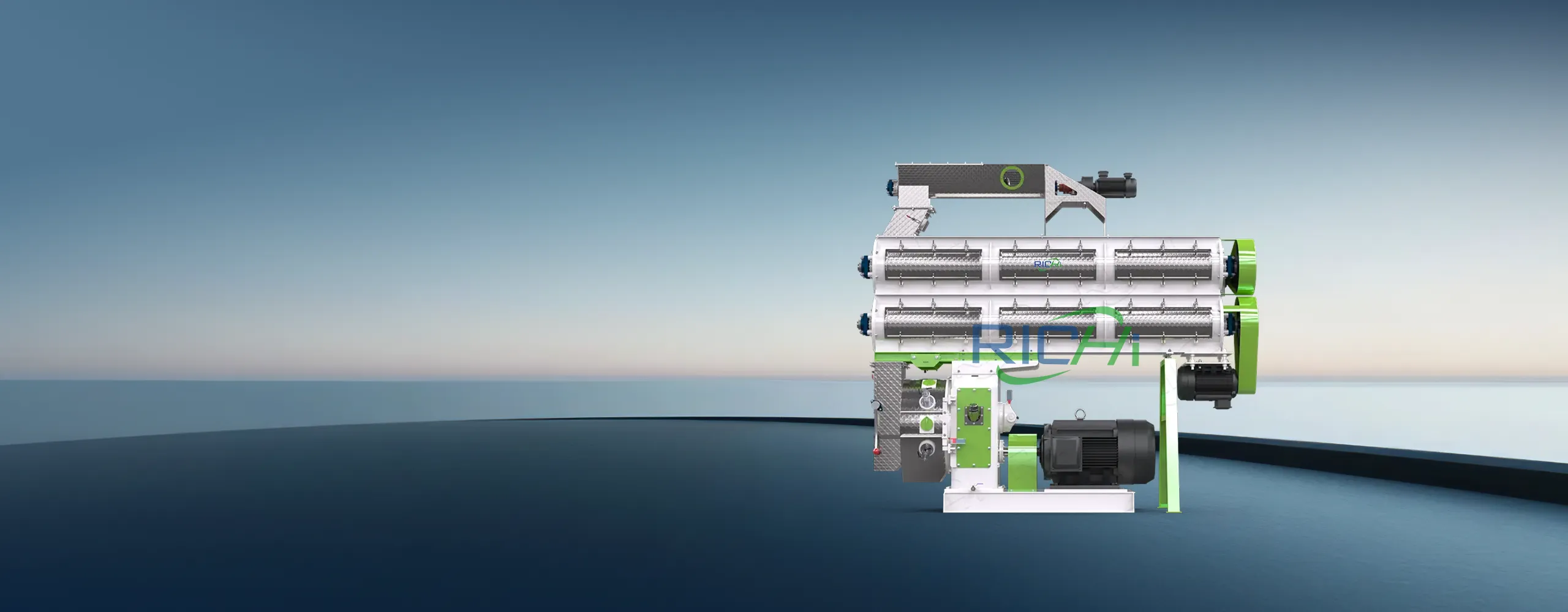

Poultry Feed Pellet Machine

Application Of Poultry Feed Pellet Machine

Our poultry feed pellet machine is widely used to produce various feed pellets for chickens, ducks, geese, turkeys, quails, pigeons, and other animals, for use in poultry farms, feed mills, breeding cooperatives, and family farms.

Furthermore, the raw materials used in our poultry pellet machine are not limited. It can process and grind a variety of crops, including corn, sorghum, soybean meal, sugarcane by-products, and oilseed meal, making one machine suitable for multiple raw materials.

Corn

sorghum

soybean meal

sugarcane stalks

cassava

sunflower meal

rapeseed meal

wheat bran

In addition to crop-based raw materials, special ingredients such as insect protein, single-cell protein, and animal by-products are also suitable. American customers use our poultry feed pellet machine with black soldier fly larvae protein as the raw material; Japanese customers use our pellet machine with DHA algal oil as the raw material; and Australian customers use our pellet machine with beef bone meal as the raw material, etc.

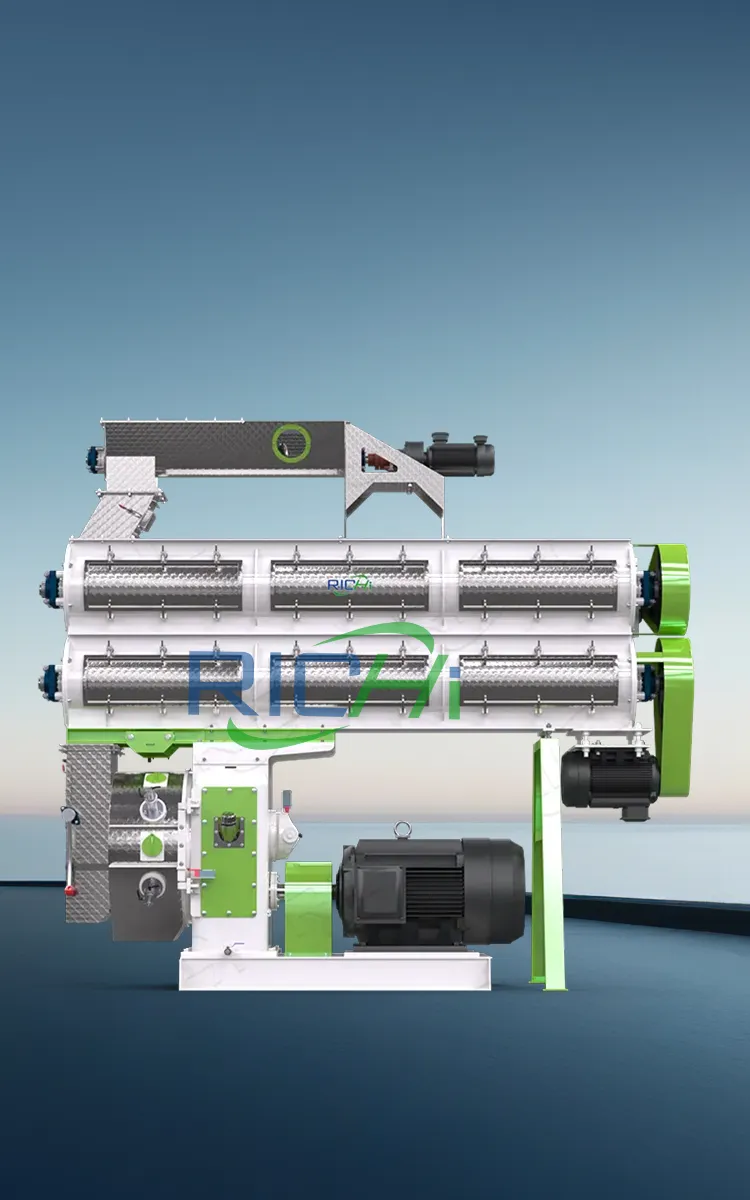

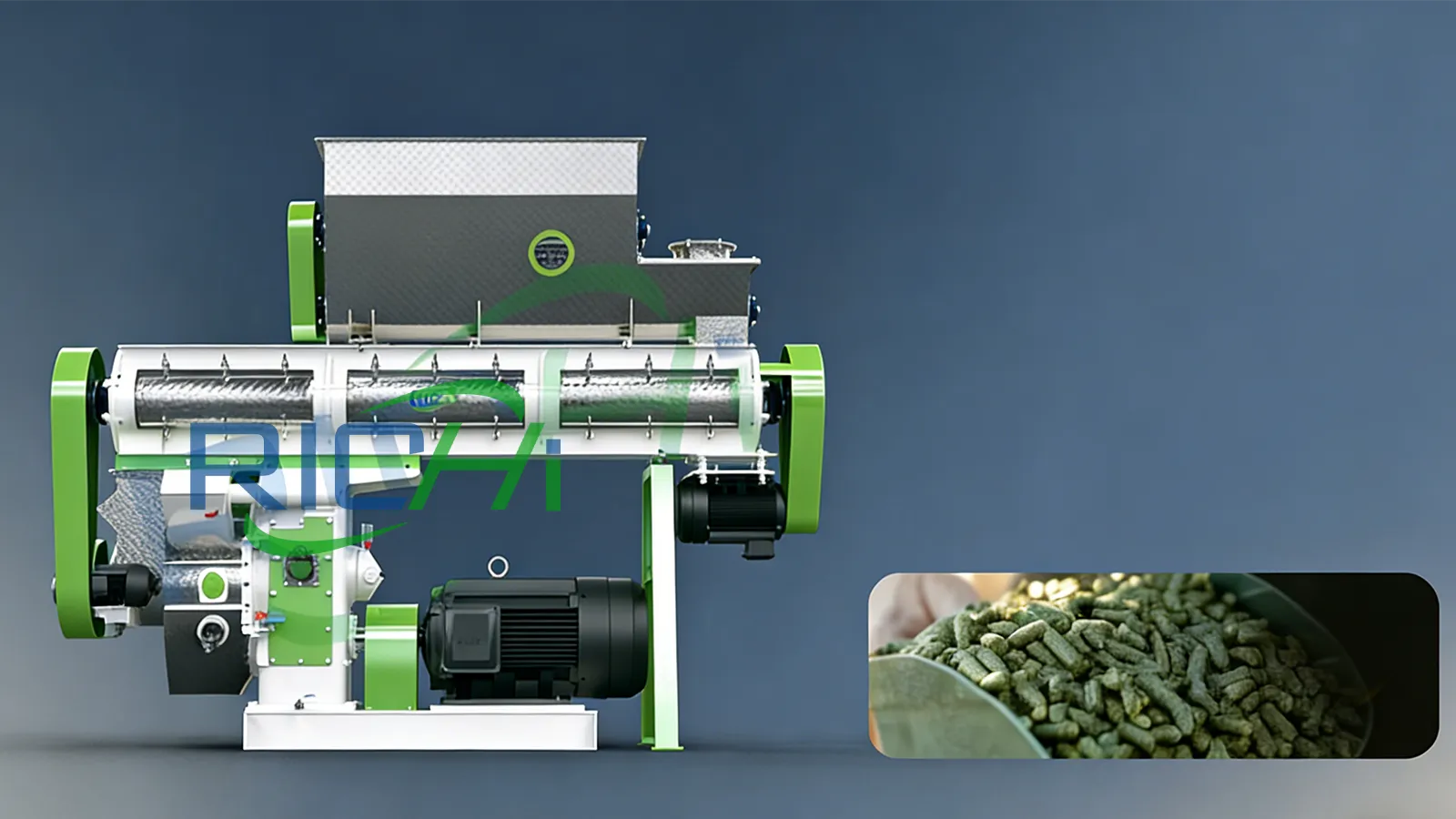

The Structure Composition Of Poultry Feed Pellet Machine

The structure of a poultry feed pellet machine is not complex, consisting of a feeding system, conditioning system, conveying system, pelletizing system, driving system, and lubrication system.

Feeding System

RICHI’s feeding system employs a variable‑frequency feeder, which is specifically designed for handling raw materials characterized by poor fluidity and large density variations, such as bran, alfalfa meal, and cottonseed meal.

Conditioning System

A single-layer conditioner is often used for ordinary feed (such as layer and broiler finishing pellets). For higher‑requirement products (like broiler starter feed or export‑grade feed), a double‑layer conditioner is recommended.

chute

Poultry feed raw materials are mixed in various proportions, and the chute leading to the pelletizing chamber needs to have good wear resistance, strong corrosion resistance, and anti-sticking properties. RICHI poultry feed pellet machines meet all these requirements.

Pelletizing System

High-starch materials like corn and wheat suit ring dies with a medium-to-low L/D ratio (4:1–6:1); ordinary carbon steel is sufficient. In contrast, high-protein and high-fiber materials need wear-resistant ring dies and high-grip rollers.

Driving System

RICHI pellet making machines for poultry feed use a 4P Siemens motor as the main drive, making the pellet mill run more stably, with less vibration, lower noise, and higher overall efficiency.

Lubrication System

During operation, poultry feed pellet machines wear due to abrasive raw materials (e.g., sunflower hulls, stone powder), internal friction, and idling. Regular addition of engine oil and lithium‑based grease greatly extends their lifespan.

Poultry Feed Pellet Machine Model

When designing poultry feed pellet machines, RICHI focuses on the user experience. Through years of manufacturing experience, we have developed a range of pellet mills with different models and power options for you to choose from.

| poultry feed pellet machine | ||||||||

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

| Main Motor Power(kW) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power(kW) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Conditioner Power(kW) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring Die Inner Diameter(mM) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellet Diameter(MM) | 2~12 | |||||||

| Capacity(T/H) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

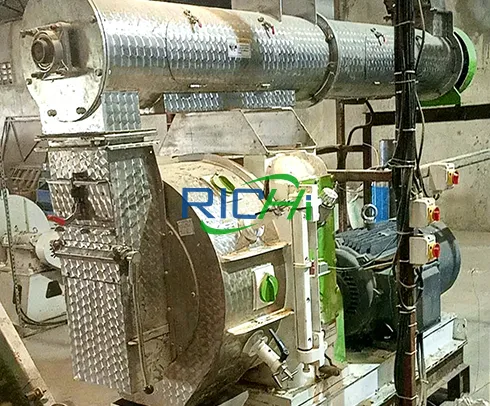

poultry feed pellet machine trial run

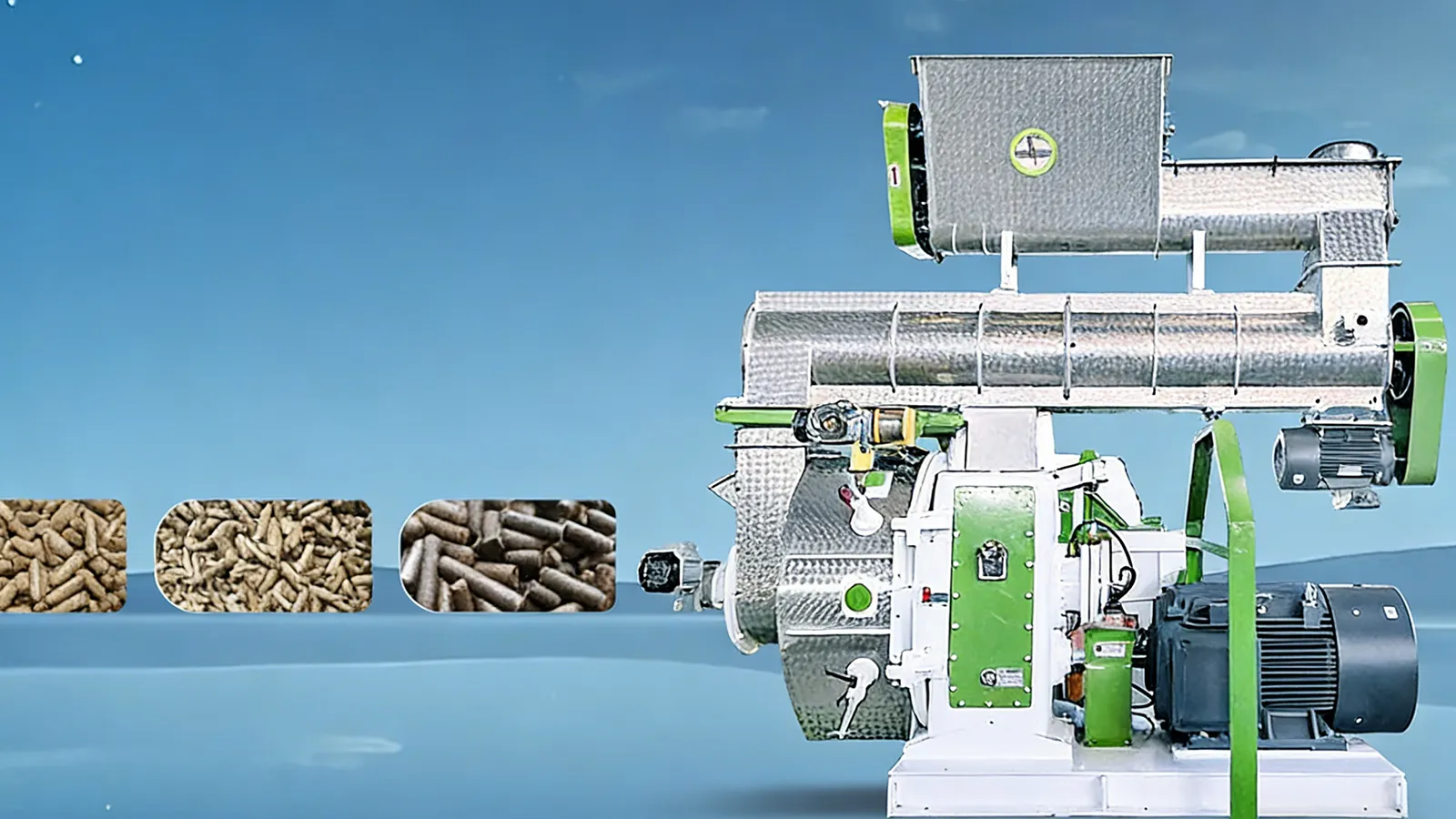

Working Principle

The pre-crushed, powdered material enters the variable-frequency feeder, and the material is transported into the conditioner via the feeder’s variable-diameter rotating shaft.

The conditioner is a crucial part of poultry feed production. In this stage, dry saturated steam must be used to ensure stable pressure and a moisture content of no more than 5%.

At the same time, the conditioning temperature needs to be maintained at 80-88℃, and protein-based materials require fine-tuning to ensure thorough sterilization and gelatinization.

In the pelletizing chamber of the poultry feed pellet machine, the rollers compress the gelatinized material, and the cutter cuts out uniform finished pellets according to requirements.

Advantages And Features Of Poultry Feed Pellet Machines

In poultry feed production equipment, the poultry feed pellet machine is the core component. A reliable and durable pellet mill is crucial for a smooth production process and high-quality finished pellets.

A customer in Russia has been using a RICHI poultry pellet machine for 8 years. Even with the rapid development and scaling up of the poultry industry, the pellet mill continues to generate economic benefits for the factory, thanks to proper maintenance.

More Stable Operation

The variable-frequency feeder, paired with a 4P-driven Siemens motor and using SKF bearings, ensures the continuous supply of raw materials during the pelletizing process, preventing the machine from running idle and resulting in a more orderly and stable operation.

High Nutritional Value

The mixed materials processed through the 304 stainless steel conditioner exhibit higher levels of cooking and sterilization, thereby ensuring the complete safety of poultry consumption. Simultaneously, this process effectively prevents poultry from being picky eaters.

Good Economic Benefits

The finished pellets produced by the RICHI poultry feed pellet machine solve the problems of waste and excessive dust associated with powdered feed. Additionally, the pelleted feed contains more nutrients, which can effectively enhance meat and egg production.

Related cases of Poultry Feed Pellet Machines

For the past 30 years, RICHI Machinery has focused on the manufacturing and technological improvement of poultry feed pellet machines.

Simultaneously, it has designed and built numerous poultry feed pellet plants and production lines. Today, its poultry pellet machines have been sold to many countries, including Brazil, Peru, South Africa, Russia, and Uzbekistan.

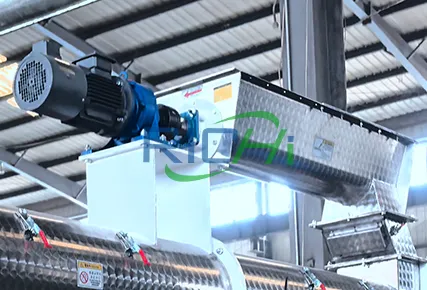

poultry feed pellet machine in Uzbekistan

This batch of poultry feed pellet machines is used in a feed project with an output of 10-15 tons, mainly producing broiler and layer chicken feed.

- Output(T/H) : 10-15

- Model : SZLH420

- Power(KW) : 110

poultry pellet making machine in Kazakhstan

The customer mainly uses the poultry pellet machine to produce 5‑6 tons of feed. This project is distinctive in its use of sunflower seed meal and hulls as raw materials.

- Output(T/H) : 5-6

- Model : SZLH350

- Power(KW) : 55

poultry feed pellet machine in Vietnam

This project mainly produces chicken feed, requiring a relatively small output. The customer uses corn, cassava, soybean oil, palm oil, and palm kernel meal as raw materials.

- Output(T/H) : 1-2

- Model : SZLH250

- Power(KW) : 22

poultry pellet machine in South Africa

This pellet mill is mainly used in a 15-ton broiler feed production project. The customer uses corn, cassava, and cottonseed meal as raw materials.

- Output(T/H) : 15

- Model : SZLH508

- Power(KW) : 160

poultry pellet machine in Afghanistan

This Afghanistan project primarily produces chicken feed. The client is a medium-sized feed mill specializing in chicken feed, with an output of about 10 tons per hour.

- Output(T/H) : 10

- Model : SZLH420

- Power(KW) : 110

poultry feed pellet machine for sale Brazil

The customer purchased a poultry pellet making machine for a 30 TPH project, producing feed including chicken feed, pig feed, and cattle feed.

- Output(T/H) : 30

- Model : SZLH508*2

- Power(KW) : 160*2

poultry pellet machine in Malaysia

In this project, the main raw materials are corn, starch residue, and soybean meal. The client requires a production capacity of 3-4 tons per hour.

- Output(T/H) : 3-4

- Model : SZLH320

- Power(KW) : 37

poultry feed pellet machine in Uganda

The client established a small poultry feed factory locally, with a production capacity of 5 tons per hour. The main raw materials are corn, sorghum, sweet potatoes, peanut shells, and peanut meal.

- Output(T/H) : 5

- Model : SZLH350

- Power(KW) : 55

poultry pellet machine in Ghana

This project is our 23rd feed production line project in Ghana, with a production capacity of 3-4 tons. It is used to produce different types of chicken feed.

- Output(T/H) : 3-4

- Model : SZLH320

- Power(KW) : 37

poultry feed pellet machine in Morocco

The client built this production line with a capacity of 1-2 tons per hour, mainly for processing feed for their own broiler chickens, with extremely low investment costs.

- Output(T/H) : 1-2

- Model : SZLH250

- Power(KW) : 22

poultry pellet making machine in Russia

This project has an annual production capacity of 50-60 tons. This is currently the largest-scale Russian feed production line project we have built.

- Output(T/H) : 50-60

- Model : SZLH508*4

- Power(KW) : 160*4

poultry pellet machine in Tanzania

The client uses our poultry feed pellet machine mainly to produce chicken feed, with a production capacity of 8-10 tons per hour. The raw materials used are corn, cottonseed meal, and cassava.

- Output(T/H) : 8-10

- Model : SZLH420

- Power(KW) : 110

Related Videos

RICHI’s poultry feed pellet machines, sold in many regions, have received continuous positive feedback from customers. Below are videos sent to us by our customers in Russia, Uzbekistan, Afghanistan, and Oman.

The Entire Process Of Poultry Feed Pellet

The poultry feed pelleting process mainly includes six stages: crushing, mixing, pelleting, cooling, screening, and packaging. Simultaneously, we equip different operating equipment at each stage to meet the diverse needs of different customers, thus ensuring the maximization of economic benefits in poultry feed pelleting.

Drying

The drying stage is not a necessary stage for every equipment setup; it mainly depends on the moisture content of your raw materials. The ideal moisture content for poultry feed pelleting is 12%-13%.

Crushing

Before pelleting, materials such as corn, brewer’s grains, and agglomerated fish meal need to be crushed into powder to facilitate subsequent stages, or for the production of powdered or crushed feed.

Mixing

To improve the nutritional value of poultry feed, a mixer is usually used to mix various materials before pelleting, ensuring uniform mixing of solid materials.

Liquid Addition

The liquid addition system is mainly used to add liquid nutrients such as oils, liquid amino acids, liquid vitamins, or molasses to solid materials, improving the palatability of the feed and promoting animal health.

Pelleting

Through high-temperature conditioning and high-pressure rolling, the poultry pellet machine achieves high gelatinization, cooking, and sterilization of feed, yielding pellets with greater nutritional value and improved storability.

Extrusion

To achieve higher economic value and produce higher-quality poultry feed, some customers choose to use a feed extruder machine instead of a poultry feed pellet machine for production.

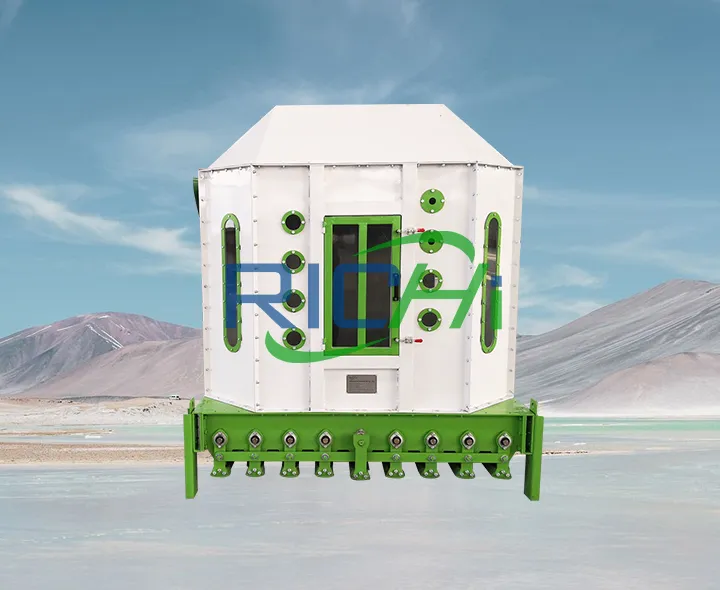

Cooling

The finished poultry feed contains rich nutrients and is at a very high temperature. It needs to be cooled by a cooler before packaging and long-term storage.

Screening

The cooled pellets will enter a rotary grading screen for screening. Unqualified crushed materials will undergo a new round of pelleting to ensure higher quality finished pellets.

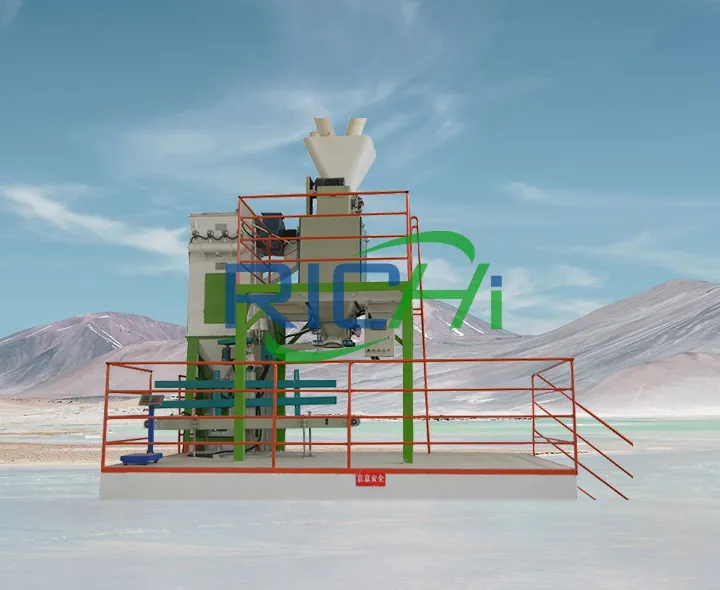

Packaging

Based on your needs, you can choose from different packaging systems with various specifications, including 5 kg, 10 kg, 15 kg, 20 kg, and 25 kg.

How To Build a Poultry Feed Mill Plant?

Building a poultry feed processing plant is a relatively complex process, involving initial planning, design and construction, commissioning, and subsequent operation.

In addition to manufacturing professional pelletizing equipment, RICHI Machinery also provides customized solutions for poultry feed plants in France, Moldova, Russia, and other countries.

Initial Planning

01

This process requires you to initially determine the type and scale of the feed mill based on the local market, deciding whether you will produce broiler feed, layer feed, or duck feed. At the same time, determine the production capacity of the feed mill based on your available capital.

Design

02

In this stage, you need to consult a professional feed mill construction company to provide you with precise technology and process flow, professional poultry feed pellet machines and related pelletizing equipment, and the design and layout of the factory warehouse, production workshop, and office area.

Construction

03

The construction process includes civil engineering, equipment installation and commissioning.

The construction company needs to build the factory according to standards, reserve openings according to the construction drawings, and perform wear-resistant treatment for the workshop.

In addition, the equipment installer needs to provide you with precise, one-on-one installation.

Commissioning and Operation

04

Once the feed mill is completed, it can be put into production. During this process, you need to conduct quality control, profit forecasting, and subsequent operational optimization.

Why Choose RICHI?

RICHI Machinery has been manufacturing pelletizing equipment for 30 years, completing over 2000 pellet production projects and selling over 10,000 pieces of pelletizing equipment.

High Quality

From raw material inspection to final testing and commissioning, RICHI Machinery focuses on every manufacturing detail, striving to create the highest quality and most economical pelletizing equipment.

Excellent Service

Whether it’s your first inquiry or a repeat purchase, RICHI will provide you with the highest quality service, from solution design and logistics to installation, after-sales support, and lifelong technical assistance.

Extensive Experience

RICHI Machinery has exported equipment to over 140 countries worldwide, manufacturing high-quality poultry feed pellet machines and designing and constructing numerous poultry feed plants and production lines.

Frequently Asked Questions

How to find a reliable brand of poultry feed pellet machine for sale? How to buy the right equipment? These are the questions most customers have when buying a pellet mill. The following questions may provide you with answers.

How to find a reliable brand of poultry feed pellet machine for sale?

+

The key to choosing a reliable poultry feed pellet machine lies in on-site inspection and multi-dimensional verification. RICHI Machinery has professional sales personnel to guide you through on-site factory inspections.

At the same time, we have built multiple feed production line projects over the past 30 years. You can see details of our actual cases in our pellet plant projects, and you can also view relevant videos on the YouTube platform.

How to determine if the poultry feed pellet machine you purchased is suitable?

+

The suitability of a pellet making machine for poultry feed mainly depends on its applicability to your raw materials and the quality of the finished pellets. The best way is to conduct raw material experiments and provide a professional report.

RICHI supports you in mailing your raw materials to Zhengzhou for testing. We will have professional personnel conduct raw material testing for you and provide you with a professional raw material testing report.

Why use a poultry feed pellet machine for feed production?

+

The poultry feed pellet machine mainly uses high temperature and high pressure to roll the raw materials into high-density, high-nutritional value feed pellets.

During the process, the raw materials are more thoroughly cooked, effectively killing pathogens such as Salmonella, making the feed more hygienic and safe. Ultimately, this leads to increased meat and egg production in poultry.

What raw materials can your poultry feed pellet machine be used for?

+

It can be used for the following raw materials: grains, such as corn, wheat, sorghum, rice bran; forage, such as alfalfa powder, straw powder, cassava residue, sugarcane vines; mixed grains and forage, and small additives such as premixes.

In short, as long as it is not PVC or plastic, RICHI pellet making machines for poultry feed can be used to produce feed.

What is the price of your poultry feed pellet machine?

+

The price of RICHI poultry pellet machines ranges from $7,000 to $100,000. The specific price is mainly determined by the output size of the machine.

In addition, if you need to build a poultry feed production line, the price will increase. This is mainly determined by your individual needs and will be discussed with you by our professional sales personnel and engineers.