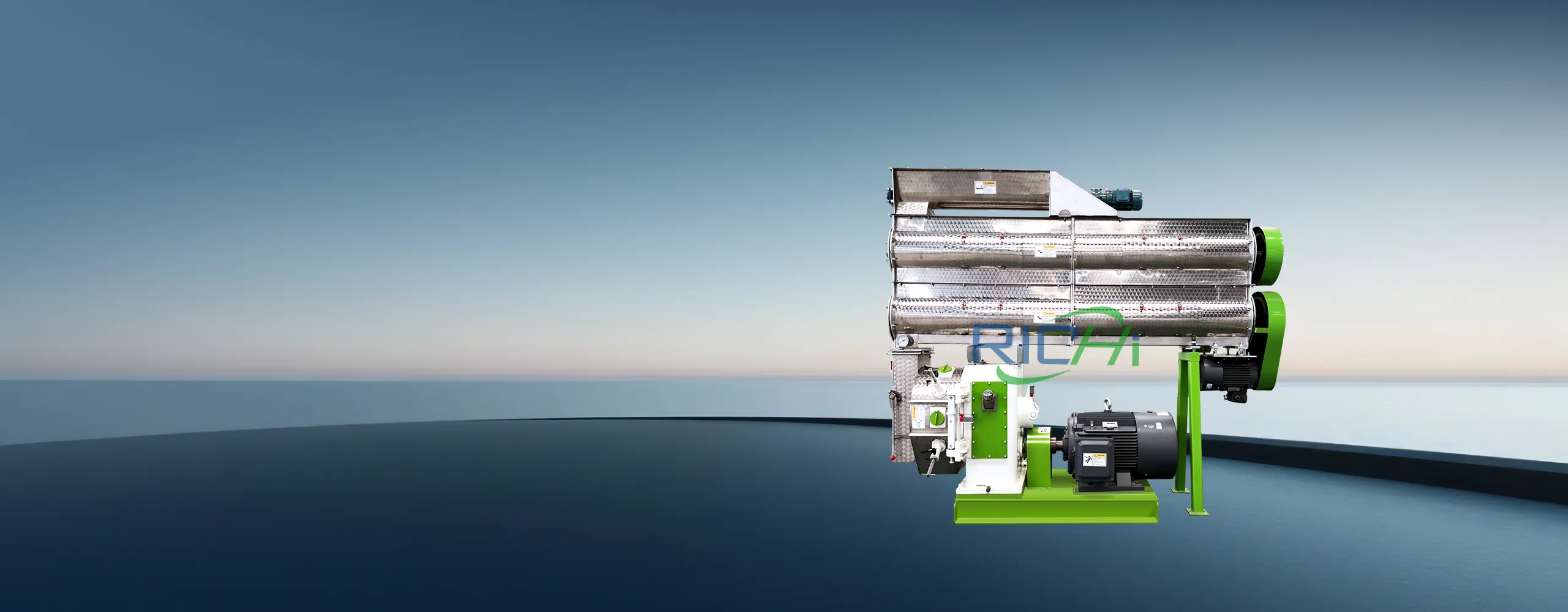

Pig Feed Pellet Machine

Application Of Pig Feed Pellet Machine

RICHI pig feed pellet machines are suitable for processing common feed ingredients. These include energy feeds such as corn, wheat, barley, and bran; protein feeds such as soybean meal, cottonseed meal, rapeseed meal, and peanut meal; and mineral feeds such as limestone powder, dicalcium phosphate, salt, and premixes.

In addition, the swine feed pellet machine can also be used for processing some special raw materials. These include animal-derived proteins, industrial by-products, functional additives, oils and fats, and emerging raw materials.

Corn

Wheat

wheat bran

soybean meal

Cottonseed meal

Peanut meal

Salt

Premix

Our German customers who purchased our pig feed machines use brewers’ spent grain as a raw material to produce sow feed; our New Zealand customers add skimmed milk powder, a unique protein source, to their raw materials to produce piglet feed; and our American customers use functional ingredients such as soy lecithin to effectively increase the binding properties of the pelleted feed, etc.

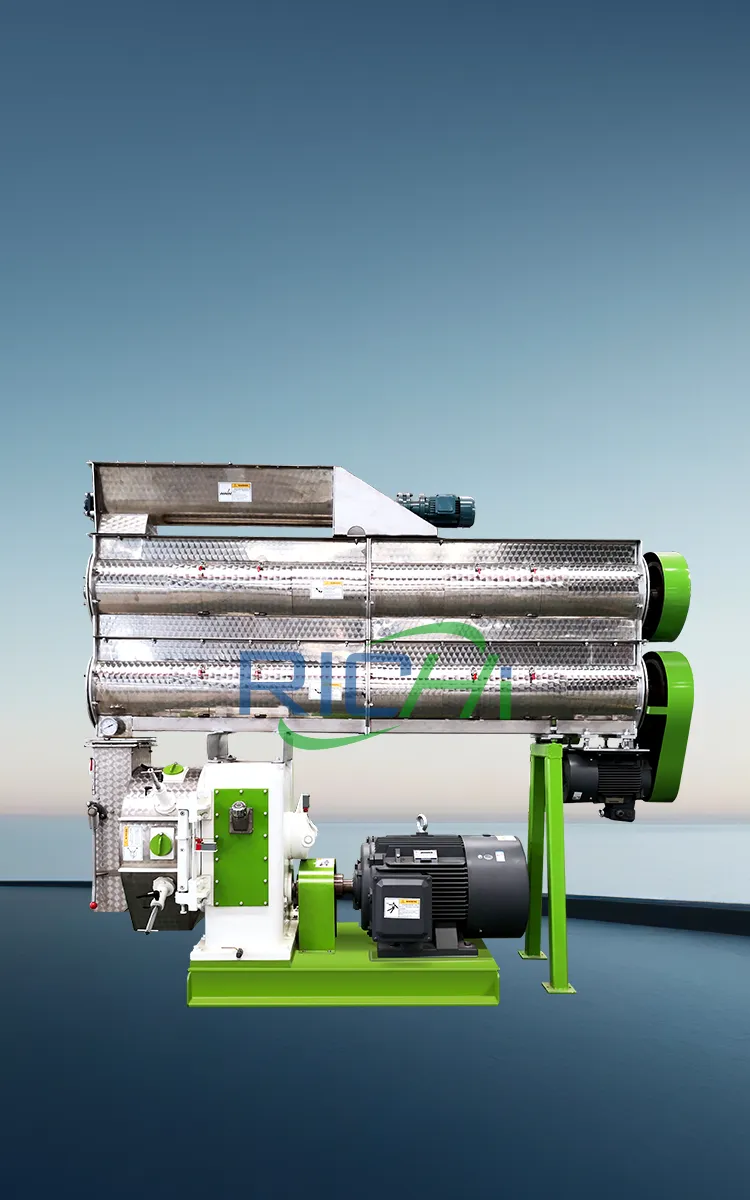

The Structure Composition Of Pig Feed Pellet Machine

The overall structure of the pig feed pellet machine is similar to that of other animal feed pellet mills, mainly consisting of the following six core components:

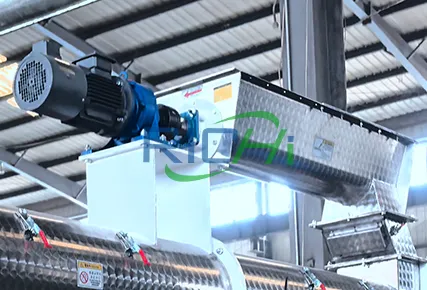

Feeding System

The variable-frequency feeder is primarily used for the precise conveying of soybean meal and premixes. At the same time, it pushes less fluid raw materials such as bran and rice husks into the conditioner, ensuring continuous production and preventing mechanical idling and damage to the machine.

Conditioning System

The high temperature of 80–90℃ (adjustable according to different material requirements) allows the materials to be fully cooked and gelatinized in the conditioner, which is conducive to the release of grain aroma, making it easier for the pellet mill to produce denser, more palatable, and more nutritious pig feed.

chute

After conditioning, the material is at a high temperature. Therefore, RICHI designed a vertical chute to allow the material to enter the pelletizing chamber vertically, effectively preventing material splashing and thus avoiding potential burns and raw material waste.

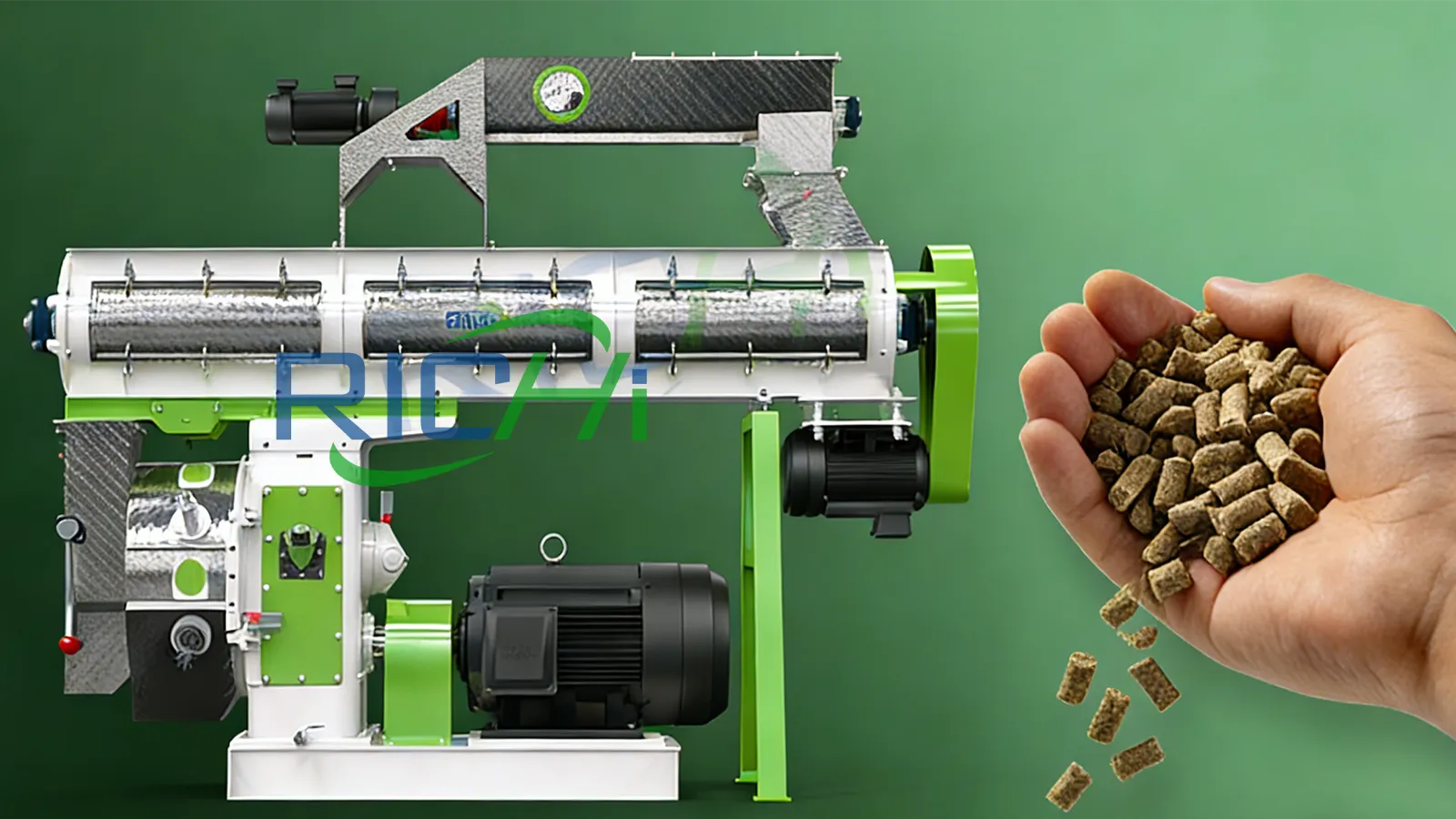

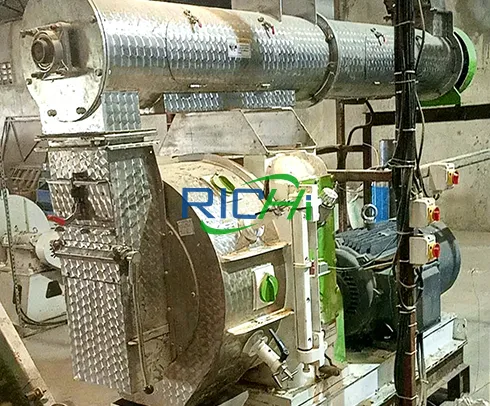

Pelletizing System

Pigs have selective eating habits, and the expensive premixes in powdered feed are likely to be left behind by the pigs, resulting in waste and nutritional imbalance. The RICHI swine feed mill uses a double-roller rolling system to produce more uniform and consistent-sized feed pellets, which are easier for pigs to swallow.

Driving System

The core of the driving system is the main motor. The entire pellet mill uses the main motor to provide the original torque for the rotation of the ring die and pressure rollers, thereby effectively enhancing the extrusion force of pelletizing and increasing the compactness of the feed pellets.

Lubrication System

Any rotating part requires regular maintenance, and the usability of a pig feed making machine largely depends on proper maintenance. Therefore, RICHI has added an automatic lubrication system to the pellet mill for efficient spray lubrication.

Pig Feed Pellet Machine Model

Pig feed pellet machines have diverse application scenarios, including family farms, individual farmers, medium-sized farms, cooperatives, large feed mills, and breeding groups. Therefore, no single machine can fully meet all these diverse user needs.

RICHI offers multiple models of pig pellet makers to provide you with the best pelletizing experience.

| Pig Feed Pellet Machine | ||||||||

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

| Main Motor Power(kW) | 22 | 37 | 55 | 110 | 160 | 185 | 250 | 315 |

| Feeder Power(kW) | 1.1 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Conditioner Power(kW) | 1.5 | 4 | 4 | 7.5 | 7.5 | 11 | 11 | 11 |

| Ring Die Inner Diameter(mM) | 250 | 320 | 350 | 420 | 508 | 558 | 673 | 762 |

| Finished Pellet Diameter(MM) | 2~12 | |||||||

| Capacity(T/H) | 1.0-1.5 | 3-4 | 5-6 | 10-12 | 15-16 | 20-22 | 30-33 | 38-40 |

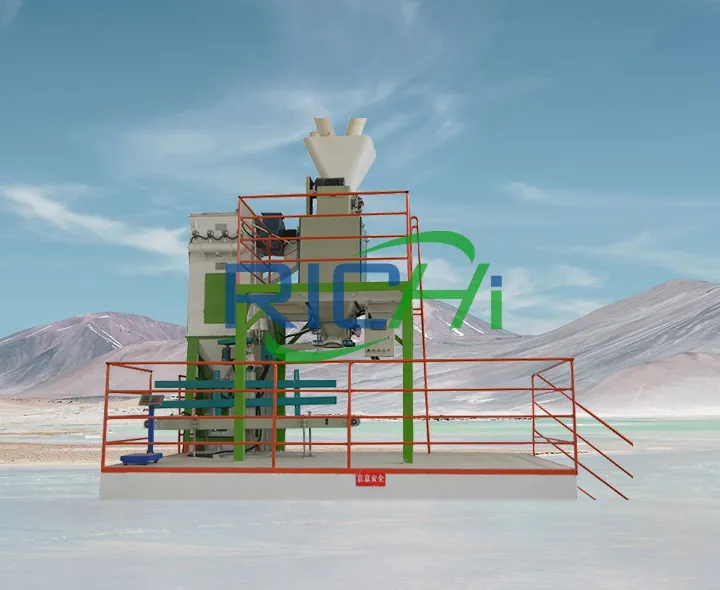

Detailed display of the swine pellet maker

Working Principle

The granulation principle of a pig feed pellet machine is essentially physical extrusion molding.

The pre-processed materials undergo high-temperature and high-humidity conditioning in the conditioner. Then they are rolled by rollers, transforming from their initial powdered form into uniform, dense, and compact pellets.

At the same time, due to the high temperature and high pressure, the nutritional components of the feed become more readily available, and the sterilization effect is more pronounced.

Advantages And Features Of Pig Feed Pellet Machines

Using a pig feed pellet machine to produce finished feed is the optimal solution considering both the feeding habits of pigs and the cost of investment.

RICHI Machinery develops pig feed pellet making machines, striking a balance between reliability, production efficiency, and customer investment costs, allowing you to enjoy a high-end pelletizing experience at a moderate price.

High-Quality Components

RICHI swine feed pellet making machines utilize 304 stainless steel conditioners, integrated forged paddles, and 40CrMnTi press rollers, coupled with globally recognized SKF bearings and Siemens motors, making the pellet mill overall high-quality, easy to use, durable, and long-lasting in performance.

Excellent Adjustment Capabilities

The pig feed pellet machine is equipped with a variable frequency feeder and features a double-roller shaft inside, easily breaking up raw materials that are difficult to feed. In addition, the feeding frequency can be adjusted according to the feeding speed, preventing the pellet mill from running idle.

High-Quality Finished Product

The modulated pig feed pellets have higher gelatinization and sterilization rates, and the rolling effect in the pelletizing chamber is better. At the same time, the cutting blades are adjustable to ensure uniform pellet length and consistent specifications, resulting in less broken material.

Related cases of pig pellet makers

Pigs at different growth stages have different requirements for finished feed pellets. RICHI pig feed pellet machines can meet the pelletizing requirements of different stages.

Our pellet mills are exported to Germany, Argentina, Bolivia, New Zealand, the United States, and the Netherlands, and have been used by customers to produce piglet feed, fattening pig feed, and sow feed.

pig feed pellet machine in Germany

In this project, our German customer uses 15% brewer’s grains, 60% corn flour, 10% soybean meal, and trace amounts of waste yeast powder and premix as raw materials to produce sow feed. We provided the customer with a complete set of feed production line equipment, priced at US$150,000-300,000.

- Output(T/H) : 10

- Model : SZLH420

- Pellet size(mm) : 2-4

pig pellet machine in Argentina

This is a large-scale farm. The customer mainly uses a typical formula of corn and soybean meal as raw materials to produce fattening pig feed, achieving high-value feed production at a low cost. Based on the customer’s needs, we equipped them with a production line with an output of 15-20 tons per hour. The complete set of equipment is priced at US$580,000.

- Output(T/H) : 15-20

- Model : SZLH558

- Pellet size(mm) : 4-6

pig feed pellet machine in Bolivia

This pig farm has 8,000 pigs. Based on the client’s needs, we designed a 3-5 T/H pig feed production line for them. In addition to using a pellet mill, the project also utilizes a raw material extruder to process raw materials such as corn and soybeans, increasing the gelatinization and cooking of starch in the materials. The entire set of equipment is priced at $95,000.

- Output(T/H) : 3-5

- Model : SZLH320

- Pellet size(mm) : 2-5

pig feed pellet machine in New Zealand

The customer in New Zealand mainly uses skimmed milk powder, barley, lactose, amino acids, etc., as raw materials to produce piglet feed. Based on the customer’s needs, we designed a pig feed production line with an output of 3 tons per hour. The complete set of equipment is priced at US$90,000.

- Output(T/H) : 3

- Model : SZLH320

- Pellet size(mm) : 2.5-3.5

pig feed pellet machine in the USA

The customer mainly uses our pig feed pellet machine to process raw materials such as 65%–75% corn, 20% soybean meal, 7% DDGS, 2% oil, and 3% premix to produce fattening pig feed, with stable output and consistent pellet quality for commercial production. The price of the complete set of equipment is $650,000.

- Output(T/H) : 30

- Model : SZLH678

- Pellet size(mm) : 4-6

swine pellet maker in the Netherlands

The Dutch customer mainly uses wheat and rapeseed meal as the main raw materials to produce complete pelleted feed for fattening pigs. The customer required a production capacity of 5-6 tons per hour. We designed a suitable pig feed pellet production line for them, and the price of the complete set of equipment is $160,000.

- Output(T/H) : 5-6

- Model : SZLH350

- Pellet size(mm) : 3.5-5

Related Videos

RICHI pig feed pellet machines adhere to uniform manufacturing standards while also considering the specific needs of each customer. We can provide you with one-on-one customized solutions.

Below are some examples of our exclusive customized pig feed pellet production projects, where you can see the actual operation of the pellet mill.

The Entire Process Of Pig Feed Pellet

The pig feed pellet machine is one of the core pieces of equipment in pig feed production. Typically, pig feed production involves six stages: crushing, mixing, pelletizing, cooling, screening, and packaging.

Drying

The drying stage is not a mandatory part of the production line and often depends on whether the moisture content of your raw materials meets the requirements for subsequent processing.

Crushing

During crushing, the raw materials are mainly broken down into smaller particles. RICHI has developed four types of feed crushers for use in different specifications of feed mills.

Mixing

Pig feed is usually not made from just one type of raw material, but rather a mixture of energy raw materials (grains, oils), protein raw materials, mineral raw materials, etc.

Liquid Addition

Liquid addition before pelletizing mainly involves adding soybean oil, palm oil, animal fat, phospholipid oil, or molasses to increase the energy concentration and palatability of the pig feed.

Pelleting

After processing, the raw materials are conditioned in a conditioning agent, and then enter the pelletizing chamber of the pig feed pellet mill, where they are rolled by double roller shafts to produce finished pellets with uniform particle size.

Extrusion

Some customers, in order to produce high-digestibility feed, piglet feed, etc., often choose to use a feed extruder machine for deep cooking and sterilization of the raw materials.

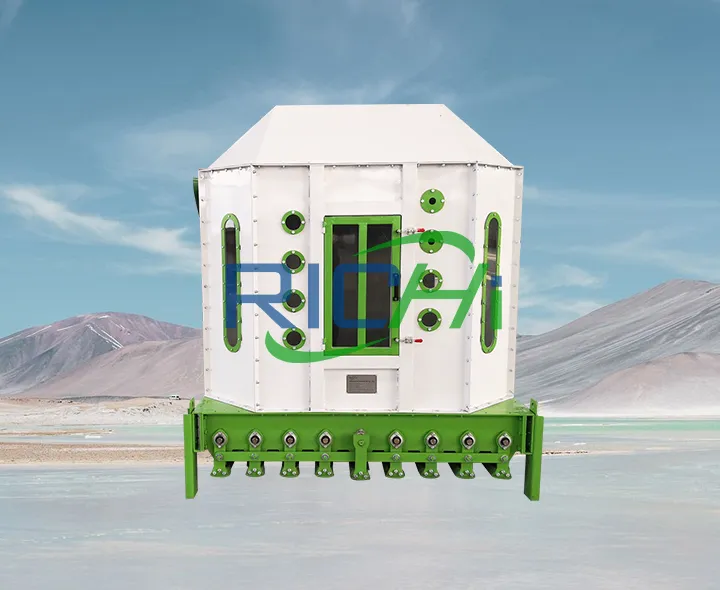

Cooling

The pig feed produced in the pelletizing stage has a high temperature and needs to be cooled promptly to prevent continuous damage to heat-sensitive nutrients (some vitamins, enzymes, probiotics).

Screening

There are many impurity removal devices in the pig feed production process, but the screening in this step mainly filters out broken finished products from the finished pellets to ensure higher quality.

Packaging

This is the final stage of pig feed pellet production. You can choose different specifications (5 kg, 10 kg, 15 kg, 20 kg, 25 kg, etc.) of packaging scales to package the finished feed.

How To Build a Pig Feed Mill Plant?

RICHI Machinery is not only a professional manufacturer of pelletizing equipment but also boasts a professional engineering team specializing in swine pellet machine solutions, pig feed production lines, and feed mills.

The construction of a complete pig feed mill involves the following steps:

Market Research

01

Before building a pig feed mill, you need to statistically analyze the local pig farming industry, including the number of pigs raised, the distribution of farm sizes, and feed consumption patterns.

Furthermore, you should analyze existing feed types, especially high-selling ones, to develop a suitable pricing strategy and market positioning.

Business Plan Development and Budgeting

02

In this process, you need to plan the target production capacity and product positioning of the pig feed pellet machine in more detail.

For example, what is the required production capacity per hour? Do you plan to produce complete feed or premixes, or determine feed types based on the pig’s growth stage?

Site Selection and Plant Layout

03

The determining factors for site selection include convenient transportation, a minimum plant area of 30 acres for a medium-sized plant, a distance of at least 500 meters from residential areas, and no sensitive points.

Most importantly, ensure sufficient power and water supply and convenient drainage.

Equipment Selection and Production Line Construction

04

In this process, you need to cooperate with a professional pig feed engineering and construction company.

It would be ideal to find a company that integrates manufacturing and trade and can also build production lines.

RICHI perfectly meets this requirement and will provide permanent technical support for your production equipment.

Commissioning and Operation

05

Once all the equipment is installed, the next step is to control the quality of the finished feed products and manage and promote the feed brand.

At the same time, you need to continuously improve and upgrade product quality.

Why Choose RICHI?

All RICHI Machinery products are certified by the ISO international quality system, EU CE certification, and Customs Union CU-TR certification. We also possess full-chain solution capabilities, with production capacity ranging from 1 to 160 T/H.

Customization

From the design and production of pig feed pellet machines to the creation of complete pig feed production lines, RICHI prioritizes your needs, dedicating itself to producing pellet mills and production lines suitable for your raw material processing.

People-Oriented

RICHI swine feed pellet mills offer user-friendly operation options with a PLC control system, enabling variable frequency speed control, automatic lubrication, fault alarms, and production statistics, reducing manual adjustment costs.

Accumulated Experience

With 30 years of experience in building over 1000 feed mills, our solutions are more mature. Therefore, what you buy from RICHI is not just equipment, but a proven pelletizing solution validated by 30 years of global practice.

Frequently Asked Questions

Whether you’re purchasing a single pig feed pellet machine or setting up your own pig feed production line, it’s a significant investment.

Therefore, careful selection is crucial to finding the right production equipment. You’ll encounter many questions during this process, and we hope the following information will provide you with some answers.

How to choose the right pig feed pellet machine?

+

The suitability of a pig feed pellet machine mainly depends on three factors: your farming scale, production capacity matching, and power configuration.

If you have fewer than 20 pigs, we do not recommend purchasing pelletizing equipment. Production capacity matching is mainly determined by calculating the daily feed requirement × 1.2 (buffer coefficient) to determine the required output. Regarding power configuration, small machines (with a capacity of 1-2 tons) generally use 220V single-phase power, while medium and large machines (with a capacity greater than 5 tons) must use 380V three-phase power.

Usually, judging based on these three factors will ensure you choose the correct pellet mill. Of course, everything should ultimately be based on your actual needs after consulting with a professional engineer.

What raw materials are suitable for pig feed pellet machines? What precautions should be taken when selecting them?

+

Suitable raw materials for pig feed pellet machines include conventional and special raw materials.

Conventional raw materials include cereals such as corn, wheat, barley, sorghum, and rice; bran such as rice bran and wheat bran; oilseed meals such as soybean meal, rapeseed meal, cottonseed meal, and peanut meal; animal proteins such as fish meal and meat and bone meal; and oils and fats such as soybean oil and palm oil.

Special raw materials include fibrous materials such as alfalfa meal and beet pulp; emulsifiers or fat coating agents; and food industry by-products such as bread crumbs and biscuit powder.

The precautions you need to take depend on your specific needs.

First, you need to determine the type of feed you will be producing. Typically, a combination of corn, wheat, and soybean meal with premixes is sufficient to meet production needs. If you are using special raw materials (such as fish meal) for feed production, it is best to check for adulteration with feather meal, leather meal, etc., by smelling or using a water immersion test, to ensure higher value for your feed production.

Secondly, you need to consider your cost investment. If you want the most stable formula, you can choose a corn and soybean meal type. To reduce costs, you can also replace 10%-30% of the corn with wheat and 10%-30% of the soybean meal with cottonseed meal.

Is any special treatment required for the first use of a pig feed pellet machine?

+

Generally, a polishing and break-in procedure is required before use. This usually involves using 70% corn flour, 20% rice bran, and 10% waste engine oil, and the pellet mill should run continuously for 40-60 minutes. The purpose of polishing and running-in is to remove burrs from the inner wall of the die holes and the surface of the press rollers, improve the overall smoothness of the machine, and extend the service life of the die.

However, some manufacturers may perform the polishing and running-in process for you in advance when installing the pellet mill. Therefore, you need to confirm the polishing process with the engineer.

Which customers are suitable for RICHI pig feed pellet machines?

+

RICHI swine pellet machines are suitable for a wide range of customers. These include companies specializing in pig feed production, including large integrated farming groups, professional pig feed manufacturers, family farms, and cooperatives.

In addition, it can also be used for the production of feed for poultry, ruminants, and aquatic animals, including chickens, ducks, geese, cattle, sheep, fish, shrimp, and crabs.

If you need to learn more about RICHI machinery’s feed pelletizing equipment, you can check out feed pellet mills, animal feed pellet mills, and feed extruder machines, or watch videos on the YouTube platform.

What is the price of your pig feed pellet machine?

+

The price of RICHI pig pellet makers ranges from $7,000 to $100,000. The specific price is mainly determined by the machine’s output capacity and functional configuration.

In addition, if a single machine cannot meet your production needs, you will often need to combine it with related equipment in a production line.

The price of a production line ranges from $10,000 to $2,800,000. The specific price needs to be finally confirmed with sales and engineers.