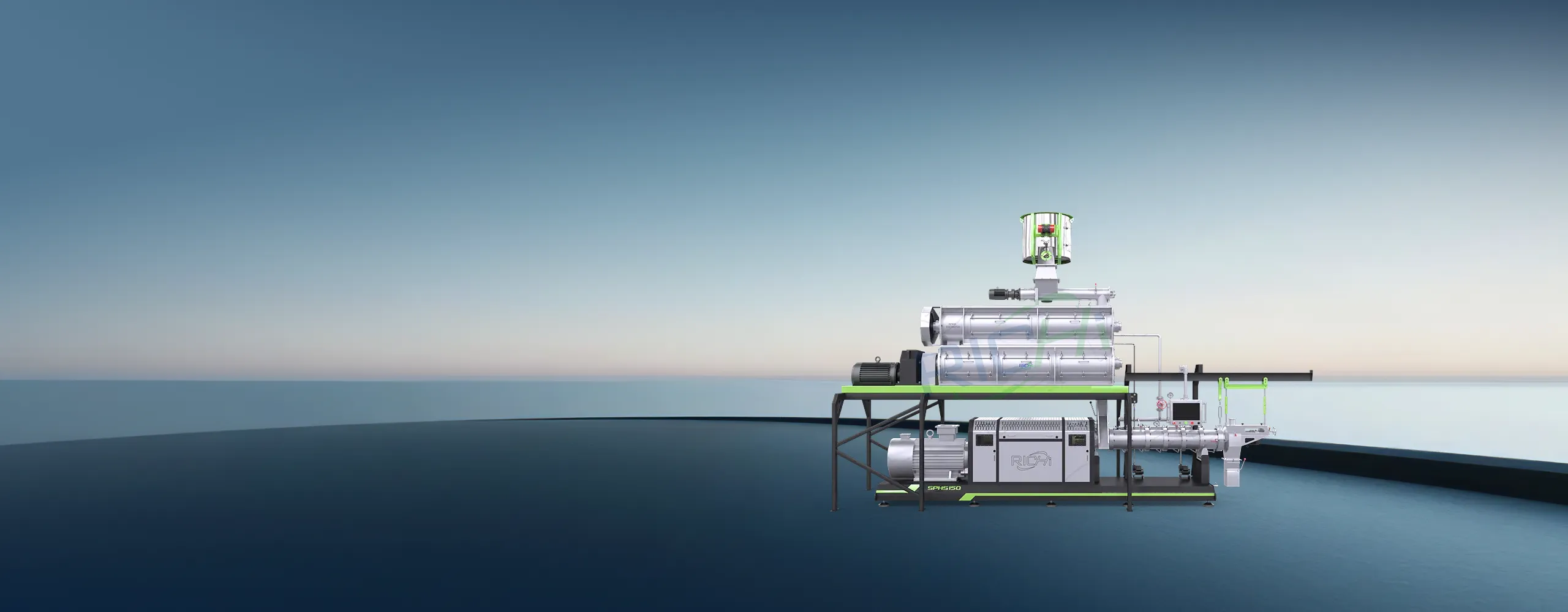

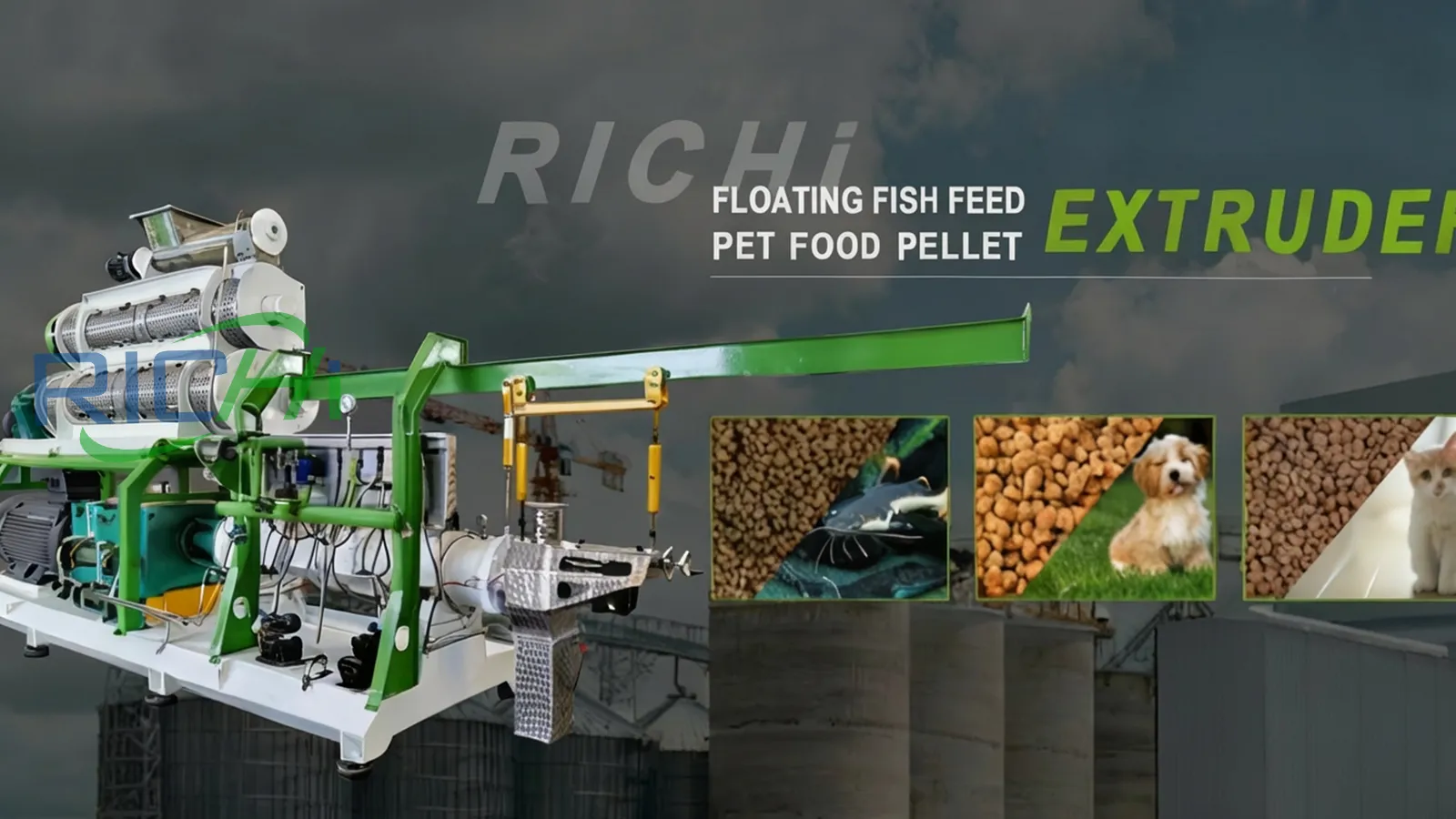

Pet Food Extruder For Sale

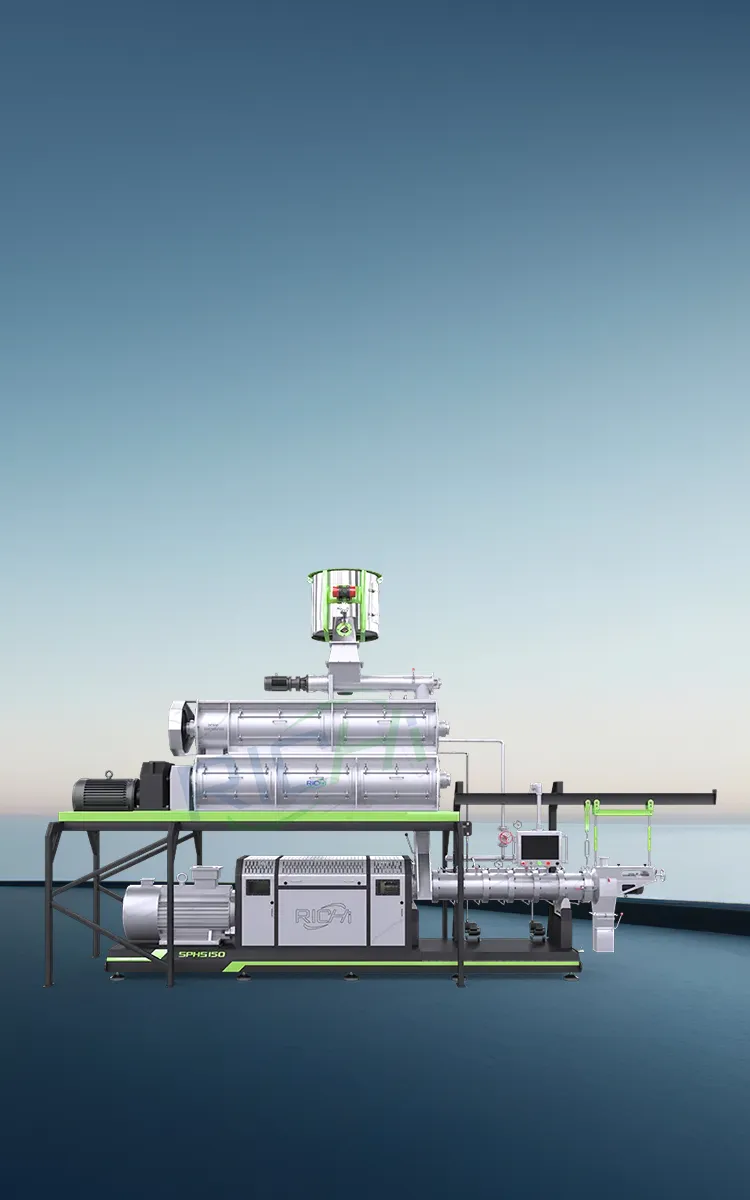

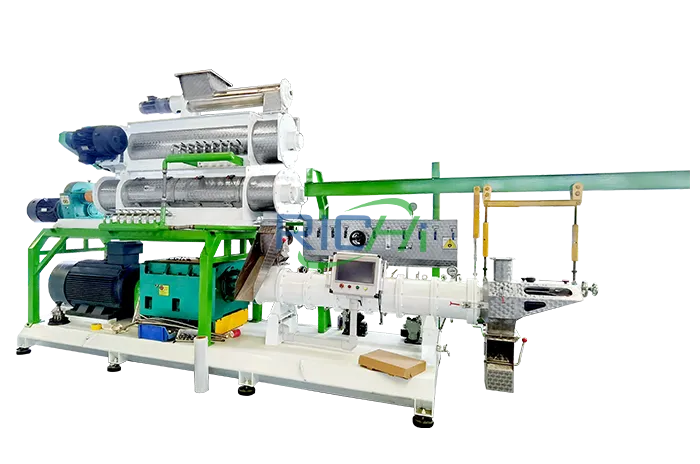

The structure composition of Pet Food Extruder

The pet food extruder for sale consists of a dual-shaft differential modulator, an extrusion puffing machine, a constant-gap soft-blade cutting device, and a Siemens main electrical system.

Below are detailed images of the pet food extruder:

Dual-Shaft Differential Modulator

Twin-screw

Constant Gap Soft Blade Cutting Device

Siemens main motor

RICHI specializes in manufacturing a high-quality pet food extruder for sale, delivering an enhanced extrusion experience for you.

Pet Food Extruder Model

RICHI pet food extruder for sale is engineered to meet diverse customer requirements, primarily offering twin-screw and single-screw pet food extruders. To facilitate your selection, the following table details specific models for your reference:

| Twin-Screw Extruder | |||||

| Model | SPHS75x2 | SPHS120*2 | SPHS150*2 | SPHS185*2 | |

| Main Motor Power (kW) | 55 | 90 | 110 | 200 | 355 |

| Screw Diameter (mm) | 75 | 120 | 120 | 150 | 185 |

| Feeder Power (kW) | 1.5 | 1.5 | 1.5 | 1.5 | 2.2 |

| Conditioner Power (kW) | 7.5 | 11 | 11 | 11 | 11 |

| Conditioner Specifications | DC400-244 | DC500-244 | DC500-244 | DC600-300 | DC600-300 |

| Differential Conditioner Power (kW) | 11 | 11 | 11 | 15 | 15 |

| Differential Conditioner Specifications | DC400*300-244 | DC500*400-300 | DC500*400-300 | DC600*500-300 | DC600*500-300 |

| Output (T/H) | 0.5-1.0 | 1.5-2.0 | 3.0-4.0 | 5.0-6.0 | 10-12 |

| Dry Process Single-Screw Extruder | Wet Process Single-Screw Extruder | ||||

| Model | DGP-90B | DGP-120B | DGP-160B | DSP-90B | DSP-135B |

| Main Motor Power(kw) | 37 | 55 | 90 | 37 | 75 |

| Feeder Power(kw) | 0.75 | 202 | 3 | 7.5 | 7.5 |

| Cutting Power (kW) | 0.55 | 1.1 | 1.5 | 1.1 | 1.5 |

| Screw Diameter (mm) | 90 | 120 | 160 | 90 | 135 |

| Overall Dimensions (mm) | 2100*1450*1350 | 2400*1950*1600 | 3100*2650*1800 | 2600*1600*1900 | 3750*1980*1950 |

| Output (T/H) | 0.2-0.4 | 0.5-0.6 | 0.8-1.0 | 0.5-0.6 | 0.8-1.0 |

Details of Twin-Screw pet food Extruder

Working Principle

Processed powdered materials enter the arch-breaking feed hopper. A variable-frequency arch-breaking feeder at the bottom pushes the powder into a dual-shaft differential mixer. This mixer uses two paddle shafts—one fast, one slow—to knead, sterilize, and gelatinize the material under high-temperature saturated steam. The gelatinized paste-like material enters the extruder.

Inside the extrusion chamber, the co-rotating extrusion screws compress the material while achieving mutual separation and self-cleaning through full meshing. Finally, through the combination of thrust shafts and angular contact ball bearings in the pet food extruder for sale, the material is instantly pushed out from the front end under high-temperature, high-pressure chamber conditions.Blades cut the material, and the finished product is discharged.

Key Technology of pet food extrusion

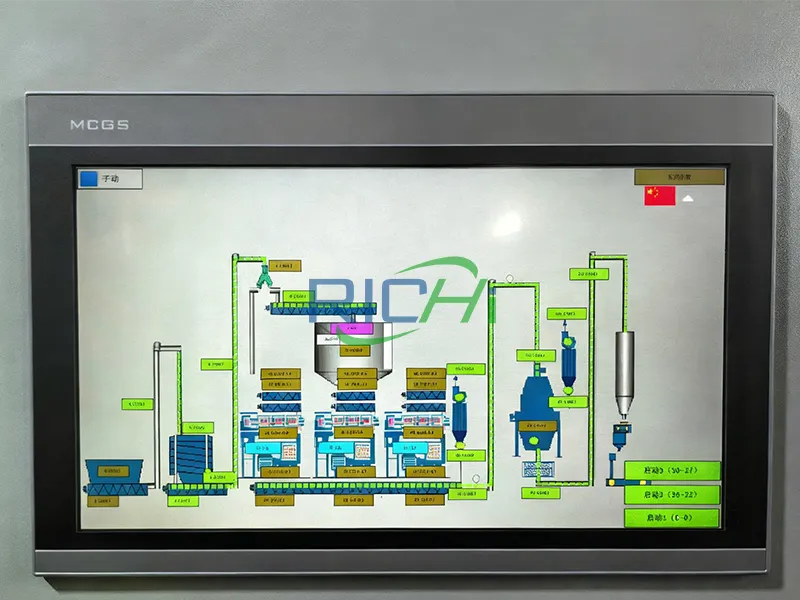

PLC Touchscreen Control System—Simplifies Operation

The RICHI pet food extruder for sale features a multi-stage recipe library capable of storing over fifty pet food formulations. Each recipe allows independent configuration of temperature, speed, and feed rate for mixing, extrusion, drying, and coating stages. With one-touch recall, switch production recipes within 3 minutes, reducing startup waste by 70% for hassle-free operation.

Variable-Frequency Main Motor — Expanding Your Operational Flexibility

Different pet foods require varying buoyancy densities and motor speeds. For dog food: 120-150 rpm; dust-suppressing cat food: 90-110 rpm; sinking aquatic feed: 60-80 rpm. RICHI pet food extruder for sale’s main motor employs variable frequency control, enabling production line switching in just 3 seconds for greater operational flexibility.

Twin-Screw Extrusion System — Ensuring Higher Product Safety

Premium cat food, functional diets, and puppy formulas demand exceptional production yield, nutritional value, and visual density. The twin-screw extrusion system achieves this through internal rotational compression, effortlessly meeting requirements for high fresh meat content, high fat levels, low filler density, refined appearance, and sterile safety. This ensures pellets emerge fuller and more uniformly sized during the extrusion-expansion process.

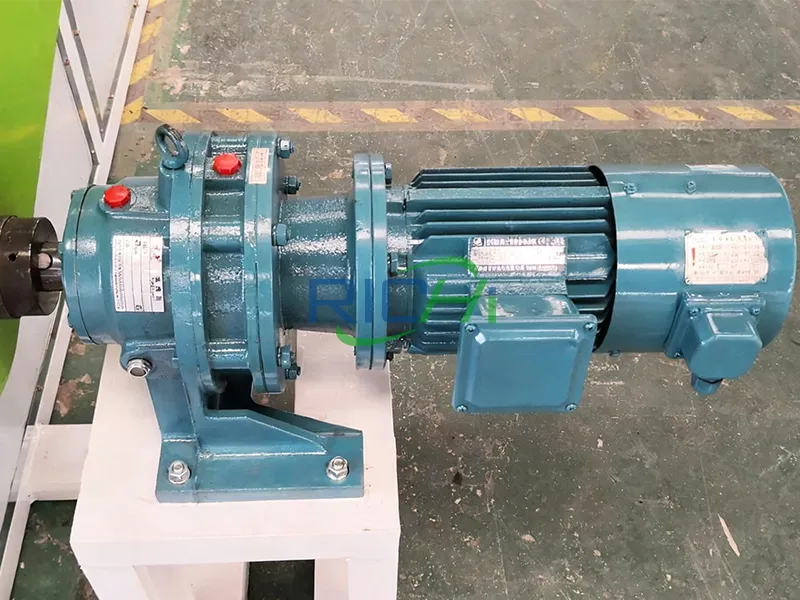

Branded Bearings — Ensuring Long-Term Stable Operation

When the twin-screw extruder’s meshing zone pushes 30% fresh meat and 40% starch forward, instantaneous axial forces can reach 80KN-120KN. Ordinary deep groove ball bearings may experience fatigue spalling. The pet food extruder for sale from RICHI utilizes FAG or SKF bearings, effectively reducing spalling frequency and ensuring stable long-term operation under high-temperature, high-pressure conditions.

Features and Advantages of pet Food Extruders

High Quality

RICHI pet food extruders utilize food-grade stainless steel in critical components directly contacting materials, such as hoppers, mixing barrels, pump heads, and die heads. This ensures corrosion resistance, rust prevention, and easy cleaning at contact points.

Core extrusion components like screws, extrusion screws, spiral parts, barrel liners, pressure rollers, and molds are constructed from high-strength alloy steel for enhanced durability and wear resistance. Other critical parts, including seals and bearings, utilize wear-resistant and high-temperature materials to ensure superior sealing.

Diverse Models

RICHI pet food extruder for sale features diverse classifications. By screw configuration, they are categorized into single-screw extruders and twin-screw extruders. By model and capacity, they are divided into small-scale, medium-scale, and large-scale machines.

By raw material and product application: specialized high-meat diets, standard grain-based diets, and specialty grain diets; By production process: basic extrusion, spray coating for flavoring, and multi-functional production. RICHI offers machinery with varying capabilities, helping you quickly identify the ideal equipment for your needs.

Superior Output

RICHI pet food extrusion equipments feature a twin-screw design with a short low-temperature zone and a concentrated high-temperature zone. This ensures vitamin loss in feed does not exceed 8%, lysine bioavailability remains at least 92%, and achieves starch gelatinization above 95%.

It enhances protein digestibility while producing pellets with a porous interior and smooth surface. This makes the feed more suitable for pets’ digestive systems, offering superior palatability and higher nutritional value, ultimately delivering higher-quality pet food production.

Related cases of pet food Extruders

Our pet food extrusion machines are sold worldwide. Next are examples of extruders sold to Iran, Uzbekistan, india, Ecuador, Bengal, and Indonesia.

pet food extruder for sale Ecuador

- Output: 4 t/h

- Main Unit Model & Power: SPHS120*2,110 KW

- Feed type: pet & fish feed

pet food extruder for sale Uzbekistan

- Output: 10 t/h

- Main Unit Model & Power: SPHS185*2, 355 KW

- Feed type: dog feed

pet food extruder for sale Indonesia

- Output: 2 t/h

- Main Unit Model & Power: SPHS120*2, 110 KW

- Feed type: dog feed

pet food extruder for sale Iran

- Output: 3 t/h

- Main Unit Model & Power: SPHS120*2,110 KW

- Feed type: dog & fish

pet food extruder for sale Bengal

- Output: 8 t/h

- Main Unit Model & Power: SPHS185*2, 355 KW

- Feed type:dog & fish feed

pet food extruder for sale india

- Output: 3-4 t/h

- Main Unit Model & Power: SPHS120*2,110 KW

- Feed type: pet & fish feed

Related Videos

The following two videos showcase pet food extruders operating in Russia and the trial run of dog food extruders within a factory.

The Entire Process of Pet Food Extrusion

The pet food extruder is merely one component within the entire production process. The entire production flow is continuous and can be divided into the following six stages:

Raw Material Reception and Cleaning Stage

01

This stage utilizes equipment such as cylindrical primary cleaners, powder cleaners, permanent magnet cylinders, and pulse dust collectors.

Grinding Section

02

Equipment required for the grinding section includes waterfall grinders, vertical-style grinders, and compact grinders.

Ingredient Mixing Section

03

Equipment needed for the ingredient mixing section includes single-shaft double-paddle high-efficiency mixers, single-shaft twin-screw mixers, and vertical mixing tanks.

Conditioning and Extrusion Section

04

This section requires equipment such as arch-breaking feed hoppers, conditioners, and pet food extruder for sale.

Drying and Coating Section

05

This section requires equipment including fan cyclones, drying drums, and airlock sprayers.

Cooling, Screening, and Packaging

06

Cooling requires counterflow coolers and cyclone pulse dust collectors. The screening and packaging section utilizes rotary classifiers and finished product packaging scales.

Other Notes

07

Production lines with varying capacities may additionally require auxiliary equipment such as bucket elevators, inclined conveyors, hoppers, and screw conveyors.

Why Choose RICHI?

RICHI Machinery delivers premium performance, European-grade delivery, and global localized service within a mid-range budget. We lock in four key risks—capital, time, energy consumption, and compliance—within the contract, maximizing your returns!

Genuine Machinery Production Capacity

RICHI Machinery specializes in designing superior machinery production capacity. Each machine undergoes a minimum 4-hour material-loaded test run before shipment, providing you with actual power consumption, actual output, and temperature rise curves.

In the floating feed industry, while DGP-160B extruders of the same model typically list 1.0T/H output but achieve only 0.8T/H in practice, RICHI’s actual output ranges from 1.05T/H to 1.1T/H.

Strong Turnkey Capabilities

RICHI operates a 108,423-square-meter self-owned manufacturing base in Jiaozuo, Henan Province. With a single-shift annual production capacity exceeding 1,200 units of various host machines and the ability to deliver over 150 complete projects annually, production ranges from 1T/H to 60T/H.

The pet food extruder for sale is installed, commissioned, and accepted in 15 days domestically, 30 days internationally.

High Resale Value

RICHI Machinery specializes in designing and manufacturing high-quality machinery that delivers reliability, durability, and superior resale value. Our equipment commands 55%-60% of new machine prices in Southeast Asian and Middle Eastern secondary markets—exceeding the industry average of 40%-45%.

This ensures easier disposal of used equipment during expansion or transition phases, reducing your upfront sunk costs.

Frequently Asked Questions

Various issues may arise during the purchase and use of pet food extruders. The following questions are provided for your reference:

Is the pet food extruder single-screw or twin-screw?

+

Pet food production demands higher standards, and twin-screw extruders are recommended for superior results. The choice of screw configuration depends on the following criteria:

Simple formulations with fat content below 10% and budget constraints may use single-screw.

High-fresh-meat, high-fat recipes requiring water flotation, slow-settling production line switching, or pellets ≤2mm should use twin-screw.

Are the production capacities of pet food extruders for sale accurate?

+

RICHI Machinery conducts 4-hour factory testing with actual materials, providing verified output, tonnage-per-kilowatt-hour consumption, and temperature rise curves. Contracts explicitly state a full refund if actual output falls below 95% of the rated capacity.

Can pet food extruder for sale process 40% fresh meat?

+

Twin-screw models feature a forced-meshing feed section, enabling direct feeding of 40% fresh meat without slippage. Single-screw units require pre-mincing for over 20% fresh meat, reducing output by approximately 30%.

What are the pellet formation rate and powdering rate for pet food extruder for sale?

+

Twin-screw pet food extrusion machine achieves over 98% pellet formation rate with powdering rate ≤1%. Pellets withstand 10-hour water immersion without disintegration, meeting export standards for Europe and America.

What is the service life of bearings and gearboxes in pet food extrusion equipment?

+

Pet food extruder for sale utilizes EA-grade self-aligning roller bearings with a design life of 20,000 hours. Gearbox lifespan is rated at 50,000 hours.

What steps are required to enter the pet food manufacturing industry?

+

From 2025 to 2030, the industry will exhibit characteristics of rapid scale expansion, structural premiumization, and global supply chain restructuring. Entering the pet food manufacturing industry essentially means establishing your own pet food processing plant, which requires the following preliminary preparations:

Project Initiation

Determine the type of pet food to be produced at the processing plant, the target pet species, and finalize the production scale of the facility.

Registration

After completing the project proposal and funding estimates, company registration and trademark registration must be carried out.

Licensing

Pet food processing plants must obtain a feed production license, a food business license, e-commerce registration, and label registration.

Construction

Once the relevant documentation is processed, the selection of the processing plant site and the construction of the processing plant can proceed.

Procurement

Following the completion of the processing plant construction, the next step involves procuring the core equipment for the facility, including the pet food extruder for sale, as well as laboratory-related equipment.

Sales

For the initial sales launch, a production volume of 2 tons can be allocated for trial sales in collaboration with 30 local pet cafes, boarding facilities, and veterinary clinics to gather the first batch of palatability data.