Pelletizer Machine For Sale South Africa

The pelletizer machine for sale South Africa include ruminant feed pellet mills, poultry feed pellet mills, aquatic feed pellet mills, and hay pellet mills, covering KwaZulu-Natal, Mpumalanga, Eastern Cape, Western Cape, Gauteng, and Free State provinces.

RICHI Machinery

Our achievements in South Africa

Pellet machine sales

12+

A commercial pelletizer machine for sale South Africa is primarily used to produce quality animal feed, premium wood chips, and Also aquatic feed pellets.

Total pellet machine sales

$3.94 mil

Based on our experience, the most frequently purchased product by South African customers is the feed pellet machine.

Market Coverage in South Africa

6

Pelletizer machine for sale South Africa cover covering KwaZulu-Natal, Mpumalanga, Eastern Cape, Western Cape, Gauteng, and Free State provinces.

Due to South Africa’s geographical location, economic development, and other factors, the local population raises a wide variety of animals, including broilers, laying hens, cattle, sheep, pigs, and various aquatic animals. This diversity in animal husbandry further dictates the need for different types of feed, while the demand for biomass pellets is relatively low.

feed pellet machine south africa

1-2 T/H Sheep Feed Pelletizer Machine For Sale South Africa

In 2019, we built another sheep feed mill in South Africa. The client has a sheep farming cooperative with 7,000 sheep. However, due to the inefficiency of the existing manual grinding and mixing line, the client needed to find a higher-value production line.

To meet the client’s high cost-effectiveness requirements, we built a production line specifically designed for processing sheep feed ingredients, effectively improving the client’s production efficiency.

- Capacity (T/H): 1-2

- Finished Pellet Diameter (mm): 6

- Raw Materials: 55% corn flour, 25% sunflower meal, 10% alfalfa meal, etc.

- Power (kW): Single unit 22, Total line 58

- Project timeline: Contract signed in July 2019, officially put into operation in September 2019

- Total Cost (USD): 30,000

6 T/H pig Feed Pelletizer Machine For Sale South Africa

The client has an integrated pig farm in Mpumalanga province, which previously focused on producing feed powder. To reduce the respiratory impact of powder feed, local regulations require pelleting for all stages of pig feed production.

Simultaneously, the client requested that creep feed be pelleted at a low temperature of 50°C. We equipped the client with a multi-temperature adjustable pig feed pellet mill to help them produce higher-quality finished feed.

- Capacity (T/H): 6

- Finished Pellet Diameter (mm): 6

- Raw Materials: Yellow corn 65%, soybean meal 18%, rapeseed meal 5%, wheat bran 6%, rice bran meal 3%, fishmeal 1%, etc.

- Power (kW): Single machine 55, entire line 120

- Project Timeline: Contract signed in March 2022, production started in July 2022

- Total Cost (USD): 160,000

Need more details about Pig feed pellet machines?

3 T/H Crayfish feed pellet machine for sale south africa

The client is an export-oriented aquaculture farm owner located in a port city in the Eastern Cape Province. When they contacted us, they stated they needed to produce sinking, high-starch crayfish feed that would remain intact in water for 6 hours. They required us to match a suitable animal feed production line for them.

Based on the client’s high demand for water resistance, we equipped them with specialized ultrafine pulverizers, crayfish feed pellet mills, and spraying machines.

- Capacity (T/H): 3

- Finished Pellet Diameter (mm): 2.5

- Raw Materials: 28% imported super fishmeal, 5% Antarctic krill meal, 3% squid paste, 18% soybean meal, 8% peanut meal, 20% wheat flour, etc.

- Power (kW): Single machine 37, entire line 95

- Project Timeline: Contract signed in June 2020, production started in September 2020

- Total Cost (USD): 85,000

Explore more details about shrimp feed pellet machines

1 T/H Floating Fish Pelletizer Machine For Sale South Africa

South Africa primarily farms tilapia and catfish, and our client has an intensive aquaculture facility. The client needed a feed production line capable of switching between multiple feed pellet die heads and continuously producing high-quality floating feed.

To meet the client’s needs, we designed and equipped the extruder with a twin-screw extruder. Simultaneously, we added an ultra-fine pulverizer and a spray coating machine to ensure higher quality finished pellets.

- Capacity (T/H): 1

- Finished Pellet Diameter (mm): 6

- Raw Materials: 65% Yellow Corn, 18% Soybean Meal, 5% Rapeseed Meal, 6% Wheat Bran, 3% Rice Bran Meal, 1% Fishmeal, etc.

- Power (kW): Single machine 110, entire line 195

- Project Timeline: Contract signed in March 2022, production started in July 2022

- Total Cost (USD): 160,000

How does a floating fish feed extruder machine operate?

15 T/H Cattle Feed Pellet Mill South Africa

This is a cattle feed mill project we built in 2017. During the consultation process, the South African client clearly stated that they had a cattle farm in the area, including beef and dairy cattle, with a total of approximately 20,000 head.

At the time of our consultation, the client already had a production line, but due to years of use, it would clog when the hay-meal ratio was high, requiring a complete rebuild of the animal feed production line.

- Capacity (T/H): 15

- Finished Pellet Diameter (mm): 6

- Raw Materials: 32% whole-plant corn silage, 18% alfalfa hay, 19% corn meal, 7% soybean meal, 5% cottonseed meal, etc.

- Power (kW): Single machine 160, entire line 500

- Project Timeline: Contract signed in March 2017, shipment in May, trial run with feed in July, official production started in August

- Total Cost (USD): 225,000

Explore more details about cattle feed pellet machines

20 T/H chicken feed making machine south africa

The customer is a large local chicken feed producer whose feed is mainly exported to Mozambique and Zimbabwe.

Based on the client’s high-volume requirements, we designed a dual-machine parallel production line to ensure a bulk density of no less than 0.68 tons per cubic meter of finished feed.

- Capacity (T/H): 20

- Finished Pellet Diameter (mm): 3.5

- Raw Materials: Yellow corn 68%, soybean meal 21%, rapeseed meal 3%, sunflower seed meal 2%, etc.

- Power (kW): Single machine 185, entire line 850

- Project Timeline: Contract signed in January 2023, production started in June 2023

- Total Cost (USD): 415,000

How does an animal feed production line operate?

Biomass Pelletizer Machine For Sale South Africa

2.5T/H Sawdust pellet machines south africa

The client already had a small wood pellet production line before contacting us, but needed to upgrade it to meet increased production demands. Raw materials primarily consist of local sawdust, wood chips, and waste wood, occasionally supplemented with straw or hay.

- Raw Materials: Sawdust, wood chips, waste wood

- Power (kW): 185

- Finished Pellet Diameter (mm): 8

- Installation Time (days): 65

- Total Cost (USD): 195,000

1.5T/H Straw pellet making machine for sale in south africa

The local straw resources are abundant. The client has an agricultural cooperative that serves over 50 farms in the area. Local industrial boilers have a significant demand for biomass fuel. The client decided to collect existing corn stalks, wheat straw, etc., and process them into biomass pellets for sale.

- Raw Materials: Corn stalks, wheat straw, sawdust, peanut shells

- Power (kW): 132

- Finished Pellet Diameter (mm): 8

- Installation Time (days): 40

- Total Cost (USD): 150,000

8T/H Wood Branch pellet mill for sale south africa

A winery needs to prune grapevines every winter, and the client found oat grass resources locally. When contacting us, they explained they wanted to mix the two to make biomass pellets to replace their coal-fired boiler. However, the raw materials have a high moisture content, which we need to address.

- Raw Materials: Grape branches, oat grass

- Power (kW): 250

- Finished Pellet Diameter (mm): 8

- Installation Time (days): 70

- Total Cost (USD): 550,000

PROJECT VIDEOs

The Top Choice for animal feed pellet machine South Africa

RICHI Machinery has completed over 2000 feed engineering projects in 30 years, and its extensive experience will bring you a superior pelleting experience.

RICHI Advantages

Explore more details about feed pellet machines

Other project types

From 2017 to 2023, three of the seven production lines are from the same customer, resulting in a 42% repurchase rate, a 60% cross-customer referral rate, 80% coverage of industry clusters, and an excellent reputation in the financing community for our pelletizer machine for sale South Africa.

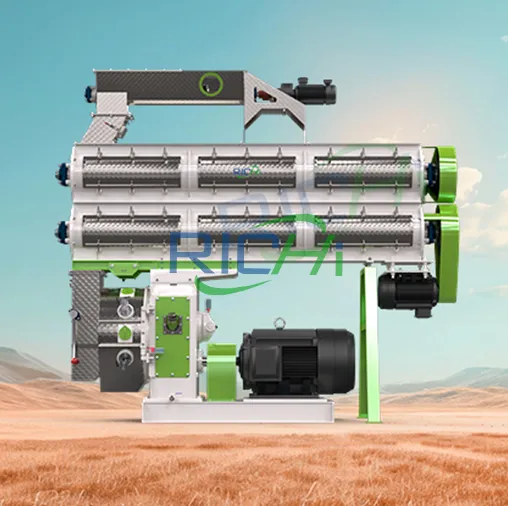

The first SZLH420 pellet mill was installed at Free State in 2017 and has since operated for over 25,000 hours, with the ring die replaced only 31 times and maintenance costs per ton below $0.8. While European-made machines on the same line enter their third year of major overhaul, Free State maintains a 99.2% uptime rate.

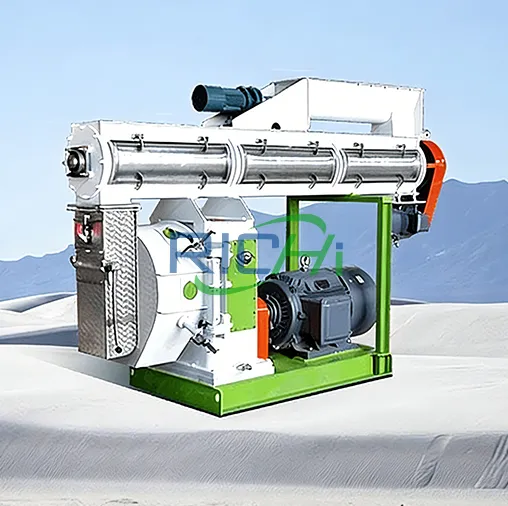

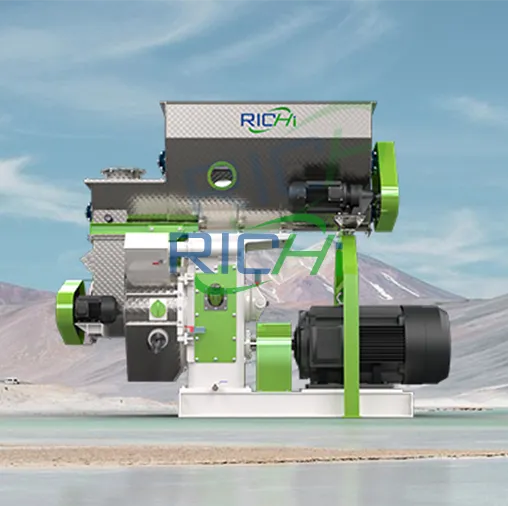

Top-Selling Pelletizer Machine For Sale South Africa

RICHI Machinery exports five popular models of pelletizer machine for sale south africa to South Africa, with power ranges spanning 22 kW to 250 kW.

RICHI MACHINE

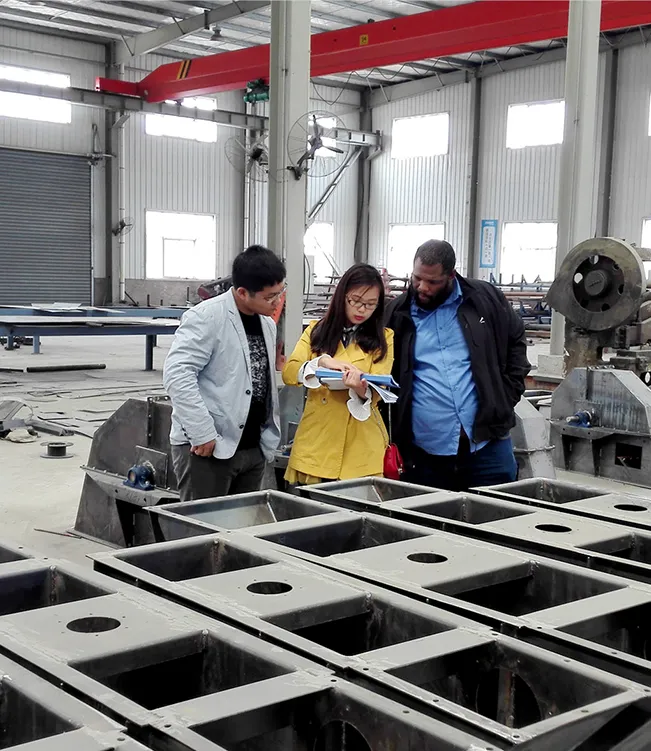

South African customer visit section display

Since 2017, more South African customers have visited our factory. They can clearly see the larger factory buildings and feel the warmth of RICHI manufacturing with their fingertips.

Every visiting customer praises RICHI’s service, which is followed by a confident sale or a follow-up order!

Why do South African customers choose RICHI?

RICHI Machinery has sold over 12 pellet mills in South Africa, and the construction of production lines covers six regions of South Africa.

Better suited to local feedstock

South African ruminant feed typically contains 30%-50% silage or hay. European models experience 3-4 blockages per shift on average. The SZLH420’s triple-layer conditioning system paired with an eccentric roller system shows fewer than 1 blockage per shift in 800-hour field operation logs, enabling continuous production without power reduction.

Minimized Downtime Losses

South Africa exempts import duties on wear parts like ring dies and press rolls for our pelletizer machine for sale South Africa, with only 15% VAT fully deductible. RICHI maintains a 1,200m² transit warehouse in Johannesburg stocking over 6 sets of 420 ring dies. Parts arrive on-site within 48 hours of notification, reducing die change time to just 2 days.

Lower Capital Investment

RICHI has established a framework agreement with local Standard Bank of South Africa for customized equipment financing leases. The total price for a 110 kW pelletizer machine is approximately $650,000 USD. Customers only need to pay a 30% down payment, with the remaining balance paid in 24 equal installments of principal and interest.

Frequently Asked Questions

When purchasing a Pelletizer Machine, you may encounter many questions. The following are questions raised by our South African customers during their inquiries, and we hope the answers will be helpful to you.

1. The power supply in South Africa is not very stable, with frequent power outages. What type of power supply does your pelletizer machine for sale south africa use?

+

This depends on the power grid configuration of your factory. If your factory currently has a stable power grid and a backup generator, we recommend using a three-phase electric Pelletizer Machine. If the power grid conditions are poor, it’s best to choose a diesel-driven or power transmission shaft-driven Pelletizer Machine.

Of course, RICHI can provide both types of Pelletizer Machines.

2.Can your Pelletizer Machine process local raw materials such as alfalfa and EFB in South Africa?

+

Yes. RICHI has specially designed a forage Pelletizer Machine for these types of materials with poor flowability. The machine is equipped with an anti-bridging feeder and a forced feeder, which can not only process these local South African raw materials but also effectively process them into high-quality pellets.

3.If wear parts of the Pelletizer Machine, such as the ring die and press roller, have problems in South Africa, can we buy replacement parts?

+

Yes. We have a parts warehouse in South Africa dedicated to our pelletizer machine for sale South Africa, and we can deliver the parts within 2-3 business days after you place your order. In addition, our press rollers and ring dies are made of alloy steel, with a service life of 1500-3000 hours, so you can use them with confidence.

4.What should I do if there are horizontal cracks on the surface of the pellets produced by the Pelletizer Machine?

+

Cracks in the finished pellets are mainly due to damage to the flared opening of the die hole caused by metal shavings. This can be solved by polishing with diamond grinding paste.

5.How long does the entire installation and commissioning process of the Pelletizer Machine take? Can you provide technical support?

+

Generally, the installation and commissioning of a single unit of our pelletizer machine for sale South Africa only takes 1-2 days, while a production line takes a little longer, about 3-5 days. RICHI has a professional technical service team in South Africa that can provide on-site installation and commissioning services. If you encounter any issues during use, please contact our technical hotline, and we will provide you with a suitable solution tailored to the complexity of the problem.

Additionally, if you have any questions or need further information, please feel free to contact us. You can also learn more through our YouTube channel.