Pellet Mill For Sale Canada

Pellet mill for sale Canada include feed pellet mill, wood pellet mills, and organic fertilizer pellet mills, serving provinces and territories such as Alberta, Nova Scotia, Manitoba, New Brunswick, Ontario, Quebec, British Columbia, and Saskatchewan.

RICHI Machinery

Our achievements in Canada

Pellet machine sales

22+

A commercial pellet mill for sale in canada is primarily used to produce quality animal feed, premium wood chips, and special clay pellets.

Total pellet machine sales

$28.44 mil

Canadian customers have a high repurchase rate for RICHI equipment, a conclusion drawn from repeat purchases by Canadian customers.

Market Coverage in Canada

8

Pellet mill for sale canada cover Alberta, Nova Scotia, Manitoba, New Brunswick, Ontario, Quebec, British Columbia, and Saskatchewan.

Biomass Pellet Mill For Sale Canada

2-3T/H wood pellet mill Canada

The client owns a timber processing plant that generates a large amount of sawdust or wood chips daily. However, due to the moisture content of these raw materials being over 50%, they were previously disposed of via paid landfill.

The client also required that the finished products from the wood pellet production line pass the EN Plus A2 test on the first attempt, and that the pellet plant be able to operate continuously for 24 hours. After learning that we are an integrated supplier of pellet plant equipment manufacturing and construction, the client decided to partner with us.

- Capacity (T/H): 2-3

- Finished Pellet Diameter (mm): 4

- Raw Materials: 70% sawdust, 30% wood chips, dry ash content not exceeding 0.5%

- Power (kW): Single unit 132, Total line 220

- Project Timeline: Contract signed in September 2022, production commencing in April 2023

- Total Cost (USD): 195,000

3T/H Maple Sawdust pellet mill for sale Canada

In this project, the client primarily used maple furniture factory waste as raw material. The old factory building already had a 1T/H production line, but with increasing resources, the old production line frequently malfunctioned, and the client planned to upgrade it.

Based on the client’s factory conditions and production needs, we designed a sawdust pellet plant with a three-channel dryer. Simultaneously, to address the height limitation of the old factory building, we adopted a compact layout with vertical drying and side discharge.

- Capacity (T/H): 3

- Finished Pellet Diameter (mm): 6

- Raw Materials: 90% maple sawdust, 10% wood shavings, incoming moisture content 55%

- Power (kW): Single machine 160, entire line 280

- Project Timeline: 40

- Total Cost (USD): 210,000

Want to learn more about wood pellet machines?

5T/H Pine and Spruce pellet machine in Canada

Northern British Columbia suffered from pine beetle infestation, leaving large areas of timber resources after the damage to the affected forests. The local government introduced relevant policies for biomass energy subsidies. The client secured a 20-year raw material supply agreement.

The client informed us that they wanted to build a medium-sized automated plant, requiring the finished pellets to be compatible with both European industrial pellet and Japanese white pellet standards. Therefore, we designed a pellet plant with two crushing sections operating in parallel.

- Capacity (T/H): 5

- Finished Pellet Diameter (mm): 6

- Raw Materials: 100% pine and spruce mixed wood chips, bark content not exceeding 5%

- Power (kW): Single machine 132, entire line 450

- Project timeline: Contract signed in October 2021, production commencing in October 2022

- Total Cost (USD): 350,000

Explore more details about biomass pellet machines

6T/H Chicken Manure Pellet Machine for sale Canada

The client is a local farm owner primarily raising broiler chickens, with many other farmers in the surrounding area raising laying hens, etc. They produce a large amount of chicken manure daily, which is difficult to process. Therefore, they contacted us hoping to build a suitable organic fertilizer production line.

Based on the customer’s raw material and site requirements, we provided them with a chicken manure pellet machine. This was complemented by a dedicated turning and mixing machine for fertilizer granulation, a fertilizer coating machine, and a trace element addition system.

- Capacity (T/H): 6

- Finished Pellet Diameter (mm): 6

- Raw Materials: 70% oat hay, 30% alfalfa, 10%-12% raw protein

- Power (kW): Single machine 160, entire line 320

- Installation Time (days): 40

- Total Cost (USD): 70,000

How does a fertilizer granulator machine operate?

feed Pellet Mill For Sale Canada

4 T/H Beef Cattle Feed pellet mill for sale Canada

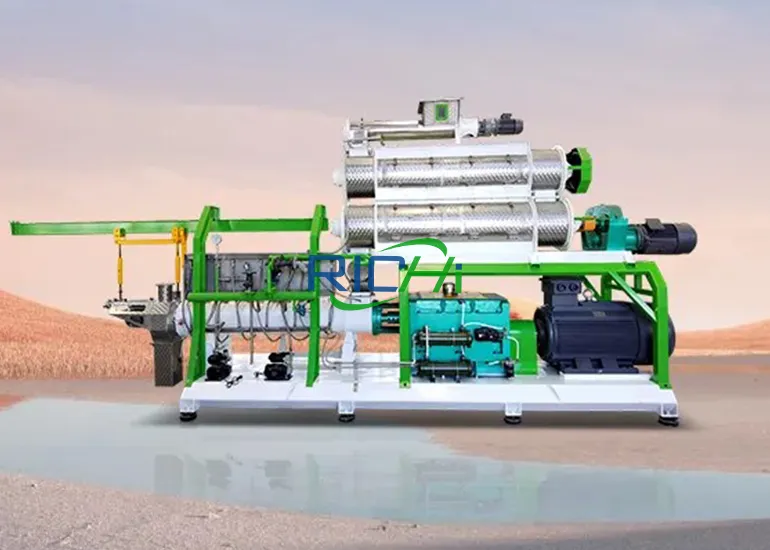

The client, a local rancher, contacted us and explained that he wanted to use an extruder to process his excess oat hay into high-energy forage feed, making it easier to feed his beef cattle during the winter and reducing transportation costs.

- Raw Materials: 70% oat hay, 30% alfalfa, 10%-12% raw protein

- Power : 90 kW per unit, 320 kW for the entire line

- Finished Pellet Diameter (mm): 6

- Installation Time (days): 40

- Total Cost (USD): 70,000

10T/H Broiler Feed pellet mill for sale Canada

This is a local integrated broiler company. The client has been in the broiler farming industry for many years. When they contacted us, they wanted to expand from raising 60,000 birds per day to 120,000 birds per day.

- Raw Materials: Corn 58%, Soybean meal 25%, Rapeseed meal 8%, Fat 3%, Premix 6%

- Power : 220 kW per unit, 650 kW for the entire line

- Finished Pellet Diameter (mm): 4

- Installation Time (days): 80

- Total Cost (USD): 225,000

5T/H Horse Feed pellet machine canada

The client told us that he wanted to establish a high-quality animal feed production line. They have abundant flaxseed resources and want to use it as one of the raw materials for horse feed production.

- Raw Materials: Flaxseed 15%, Soybean Meal 20%, Oatmeal 30%, Molasses 5%

- Power : 185 kW per unit, 400 kW for the entire line

- Finished Pellet Diameter (mm): 8

- Installation Period (days): 25

- Total Cost (USD): 50,000

RICHI Machinery

Clay pellet mill for sale Canada

This is a unique biomass project that RICHI took on in Canada. The client has abundant bentonite resources in the area and owns a cat litter factory, needing to process the clay into cat litter and other pet supplies.

Based on the client’s needs, we recommended a biomass pelletizer with a capacity of 3-4 tons per hour. The client was very satisfied after using it, telling us that the pellets produced were dense and uniform in size.

PROJECT VIDEOs

RICHI pellet mills are widely used in Canada

In Canada, RICHI pellet mills are ubiquitous, found in ranches, breweries, equestrian centers, broiler farms, timber processing plants, furniture waste treatment plants, export wood pellet mills, and refractory material plants.

RICHI’s strengths

High-quality raw materials used in equipment manufacturing

Innovative equipment and mature technology

Customer-centric service

Want to explore more?

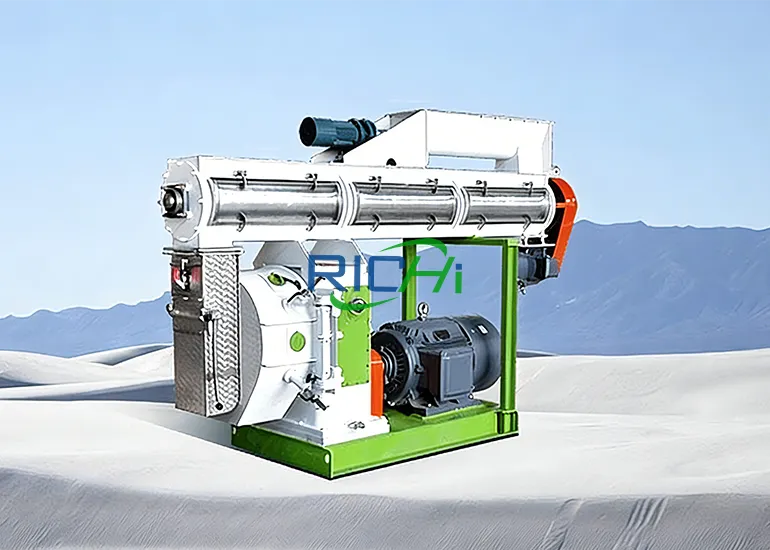

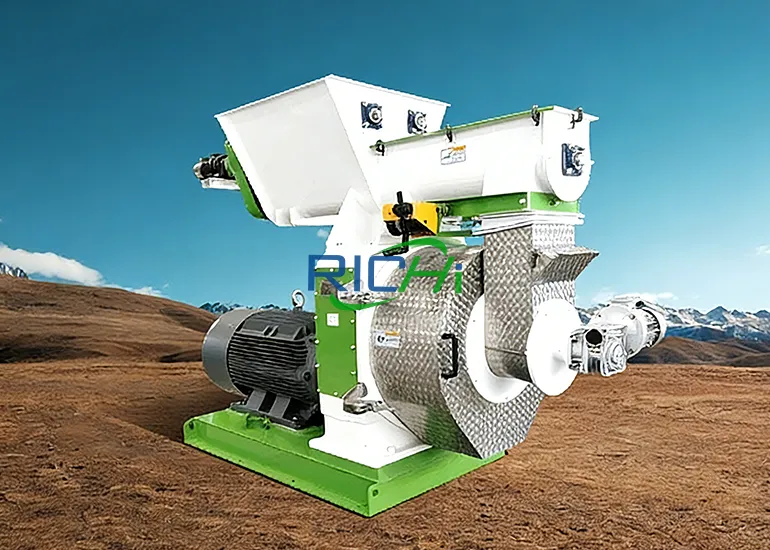

Top-Selling Pellet Mill For Sale Canada

RICHI Machinery’s best-selling pellet mills exported to Canada include three models of wood pellet mills, two models of compound feed pellet mills for livestock and poultry, and one model of feed extruder machine. Power ranges from 90KW to 220KW.

Why do Canadian customers choose RICHI?

RICHI Machinery‘s pellet mills for sale Canada have seen more than 22 units sold, generating total sales exceeding US$28.44 million and covering eight regions across the country.

One-stop certification

RICHI’s pellet mill for sale Canada comes with dual certification (CE plus CSA/UL), ensuring immediate market access and operational safety. The control cabinet is pre-configured to meet Canada’s 600V/60Hz grid and Electrical Safety Code, enabling users to pass provincial inspections without secondary modifications.

Superior Cold Resistance

This pellet mill Canada is engineered for continuous -30°C (-34°F) operation. Features include air-cooled press rolls, low-pour-point hydraulic oil, and heated self-cleaning conditioners. It maintains full-load output with high-moisture wood chips or winter grass, with a first-year failure rate below 1%, well under the North American industry average.

Short Implementation Cycle

For its pellet mill for sale Canada, RICHI provides turnkey services—from process design and bilingual (English/French) documentation to remote PLC debugging—enabling production ramp-up within 45 days of shipment. This reduces project timelines by about 30% versus European suppliers and cuts civil and labor costs by 15%-20%.

Frequently Asked Questions

When purchasing equipment, you may encounter many questions. The inquiries from Canadian customers regarding equipment issues may offer some answers.

1. Does your equipment meet Canadian and North American electrical and safety standards?

+

Our pellet mill for sale Canada have relevant certification documents. We will also provide relevant proof during your initial inquiry. Information about the complete machine will be included with the shipment.

2.What if the pellets have a high powder content and are brittle?

+

High powder content is due to improper conditioning; the material’s gelatinization is insufficient. You need to increase the steam volume by 1%-2%, raise the conditioning temperature to 85℃-90℃, and polish the die holes with abrasive material.

3.What if the pellet mill motor overheats and trips?

+

This can be resolved by reducing the feed rate, cleaning the fan heat sink, and installing a voltage regulator.

4.If critical components such as the ring die, pressure roller, and main shaft malfunction, how long does it take to obtain spare parts in Canada?

+

Fastest: 2-5 business days; Latest: 2-6 weeks.

Of course, our pelletizer for sale canada features a ring die made of 40CrMnTi material, hardened pressure rollers, and a main shaft forged from 42CrMo alloy steel—all with the primary goal of producing key components with a longer lifespan for you.

5.Canada has long winters; can your equipment operate continuously in such an environment?

+

Yes, according to customer feedback, our equipment can still operate continuously at -30°C. For the equipment to start up and operate smoothly in extremely cold conditions, regular lubrication, maintenance, and control of the workshop temperature are also necessary.

6.What to do if the pellet mill won’t start?

+

If the pellet mill cannot start, it may be due to residual material stuck in the pelleting chamber. It is necessary to clean the accumulated material in the pelleting chamber, check the electrical control fuse and contactor, and then reset the limit switch.

7.What to do if the conditioner is clogged?

+

Clogging in the conditioner of a pellet mill for sale Canada is typically caused by excessive saturated dry steam, which results in over-gelatinization of the material. To resolve this, reduce the steam flow by 10% and repair by welding or replacing the impeller, maintaining it at a 45° angle for optimal material propulsion.

If you would like to learn more, you can visit the YouTube platform to watch the videos.