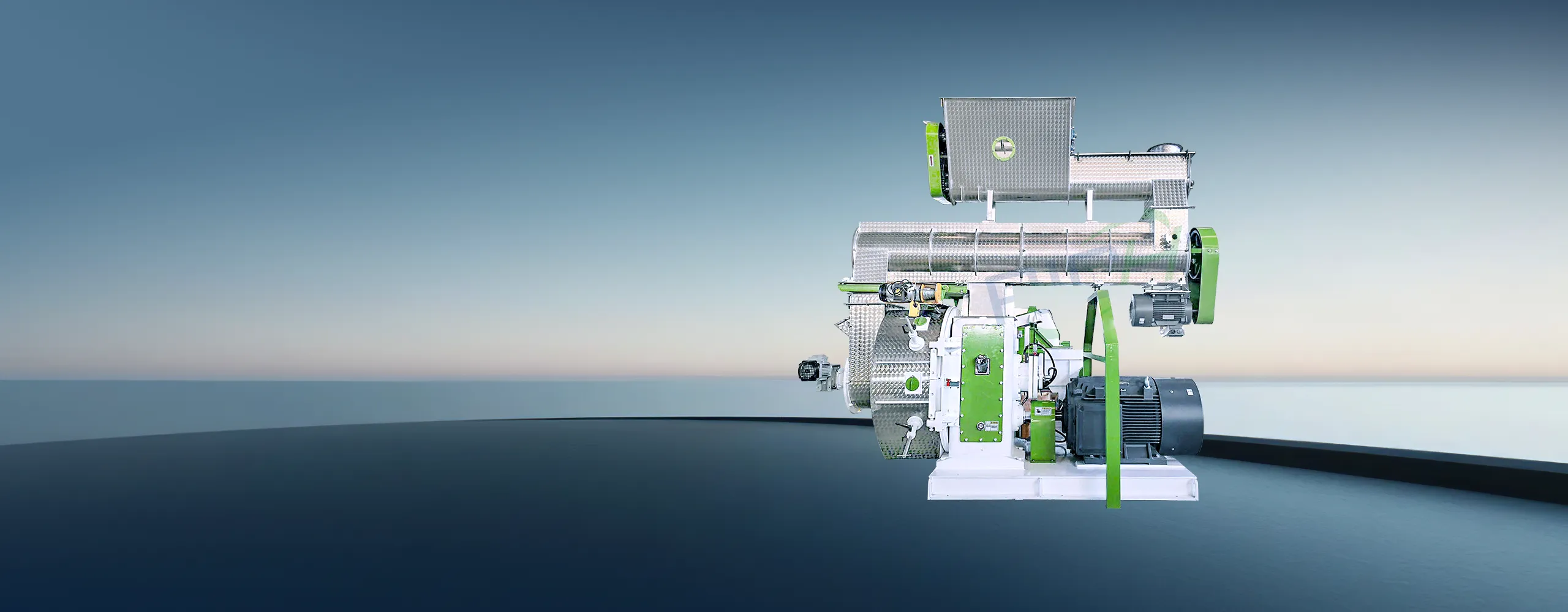

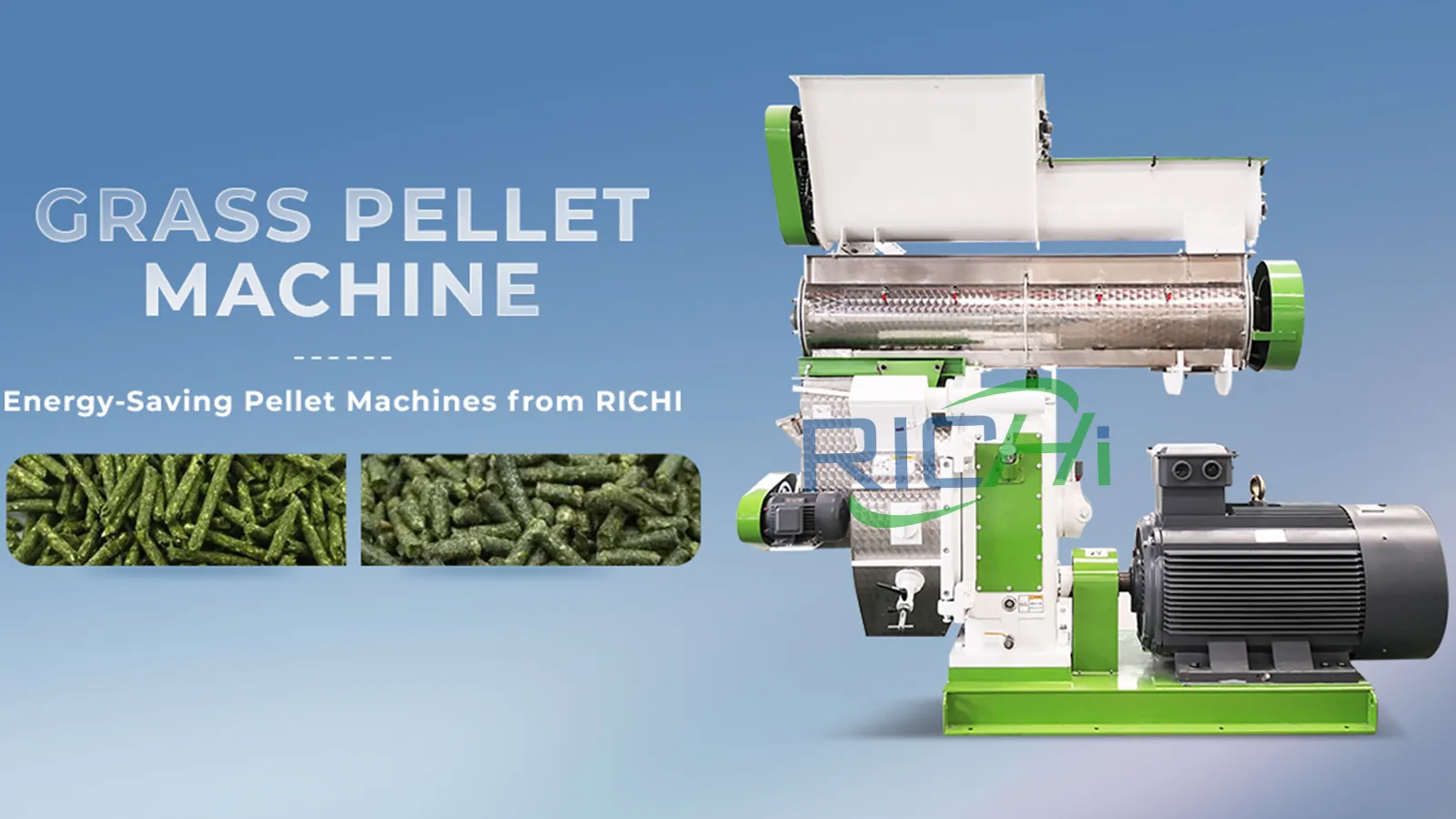

Grass Pellet Machine For Sale

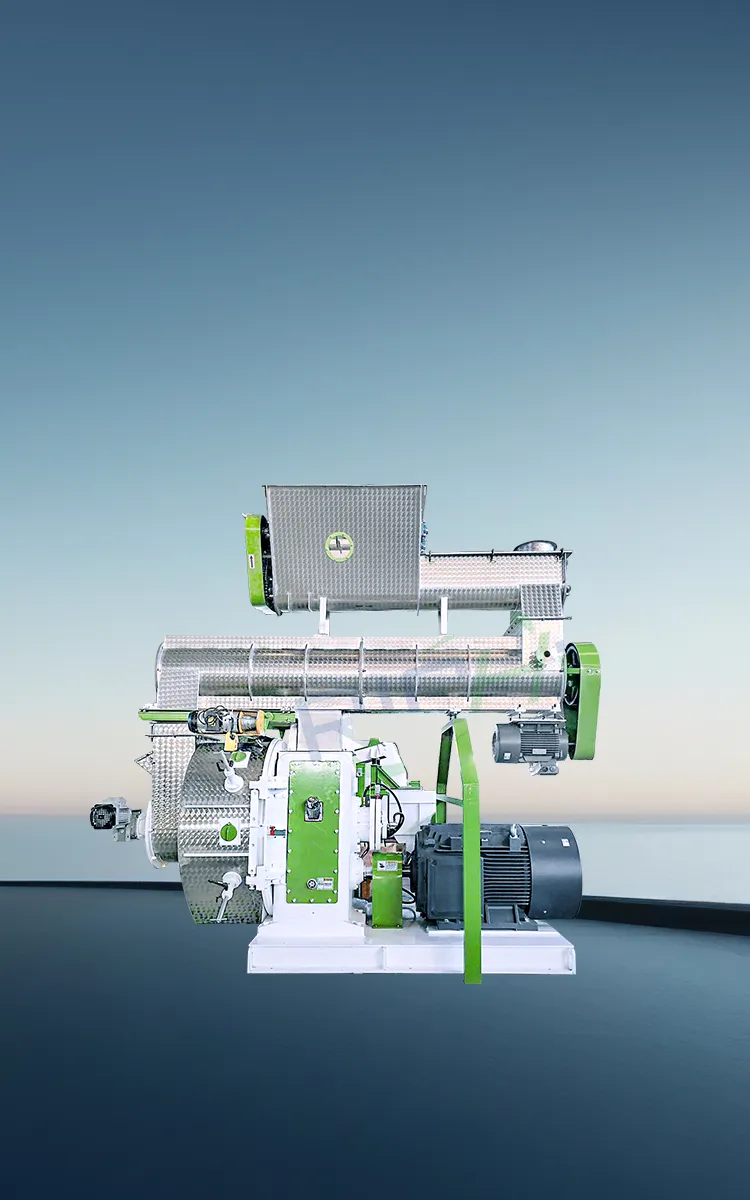

The structure composition of Grass Pellet Machine

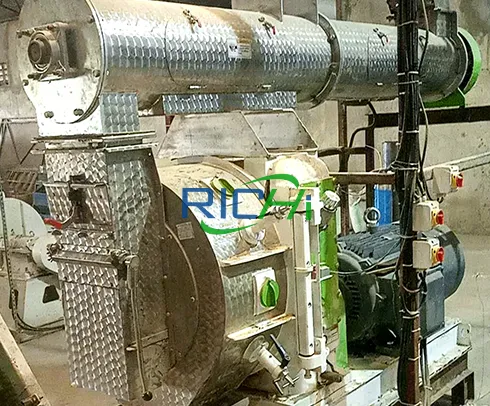

RICHI grass pelleting machines adopt a modular design, consisting of six core parts: a feeding system, a conditioning system, a pellet mill main unit, a drive system, an electrical control system, and safety protection devices.

Below are detailed images of the grass pellet machine for sale:

feeding system

conditioning system

pelletizing chamber

drive system

electrical control system

safety protection devices

RICHI grass pellet making machine crafts high-quality pelletizing equipment with meticulous engineering, delivering worry-free operation for our customers.

Grass Pellet Machine Model

RICHI grass pellet machines for sale offer multiple types tailored to diverse customer needs. Please refer to the table below to select the appropriate model:

| Grass Pellet Mill For Sale | ||||||

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

| Main Motor Power (kW) | 22 | 37 | 90 | 132 | 185 | 250 |

| Arch-Breaking Feeder Power (kW) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power (kW) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter (mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished Particle Diameter (mm) | 4~12 | |||||

| Output (T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

Test Run Video of grass pellet machine

Working Principle

The grass pellet machine for sale processes biomass materials such as straw, forage grass, and crop husks into powdered feedstock. Then this material is compressed into high-density feed pellets that are easy to store, or used as fuel pellets.

These pellets serve as nutritional supplements for cattle, sheep, camels, and other ruminants or fuel for thermal energy generation.

Key Technology Of grass Pellet Machine

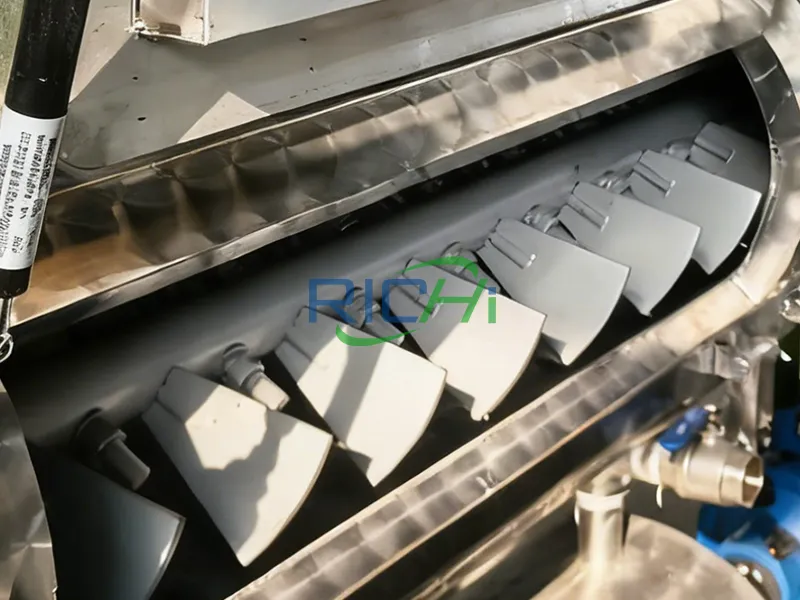

Dual-Shaft Mixing Rollers—Facilitating Material Fragmentation

Given that forage typically exhibits fibrous, highly elastic, and low-flow properties, pellets tend to intertwine and interlock when processed in a grass pellet machine for sale, forming wedge arches or compression arches. Therefore, breaking these arches is essential before pelleting.

The effectiveness of this process significantly impacts the grass pelletizer machine’s performance and the quality of the final product. RICHI’s grass pellet mill features dual-shaft mixing rollers. Their staggered operation facilitates easier material separation, achieving superior pelletization results.

Precision Steam Venting System—Offering Dual Flexibility

Optimal moisture content for forage rolling is ≤12%. During the rolling process in the pellet chamber, residual moisture evaporates. Failure to promptly vent this vapor can cause finished pellets to reabsorb moisture, mold, swell, and crack—potentially clogging the grass pellet machine for sale.

The RICHI grass pellet machine for sale features dual steam vent ports, allowing water vapor to escape smoothly. You can freely choose whether to connect and activate the fan or scraper based on pellet output, offering a thoughtful dual-venting option.

Forced Feeder—Maximizing Material Entry into the Pelletizing Chamber

The loose bulk density of hay and straw ranges from 50-150kg/m³, while processed powdered feed weighs only 0.05-0.15 tons per cubic meter—a volume spread across a double sofa that weighs merely as much as a box of A4 paper. Such extremely low-density powdered materials cannot enter the high-pressure pelletizing chamber of a grass pellet machine (grass pelletizer) under their own weight.

RICHI’s grass pellet machine for sale extends the screw shaft of the forced feeder directly to the center of the ring die, cleverly utilizing centrifugal force to fling lightweight materials into the die cavity. This ensures ample material in the pelletizing chamber, preventing the ring die from idling and enabling smoother pelletization.

520 Ring Die Lifter — Helps You Avoid Die Change Losses

During prolonged operation, ring dies in grass pellet machines for sale may become damaged or require replacement. RICHI’s grass pellet machine for sale employs double-sided carburized ring dies, enabling dual-sided usage.

Recognizing the high cost and difficulty of replacing ring dies, designers equipped the 520 model with a ring die lifter. Simply rotate the handle to effortlessly swap out the die without risk of impact damage, ensuring the ring die remains intact.

Features and Advantages of the Grass Pellet Machine

Meticulous Design

RICHI’s grass pellet machine for sale prioritizes user-friendliness, incorporating numerous details for hassle-free operation. Dual steam drainage ports allow flexible exhaust system selection; three motors independently drive the variable-frequency feeder, forced feeder, and pelletizer for efficient production. The ring die lifter enables effortless die replacement, minimizing labor downtime.

Exceptional Durability

RICHI grass pellet press features a heavy-duty enclosed steel structure body, high-grade alloy steel frame, 304 stainless steel conditioner, 42CrMo press roll shell, and carburized ring die. This design ensures a more durable body, higher-grade conditioning, sturdier press rolls, and longer-lasting ring dies, effortlessly extending the pelletizer’s service life.

Dense Pelletization

RICHI grass pellet machine for sale features a heavy-duty enclosed steel structure body, high-grade alloy steel frame, 304 stainless steel conditioner, 42CrMo press roll shell, and carburized ring die. This design ensures a more durable body, higher-grade conditioning, sturdier press rolls, and longer-lasting ring dies, effortlessly extending the pelletizer’s service life.

Related cases of grass Pellet Machines

RICHI grass pellet machines for sale, renowned for their precision engineering and premium quality, are sold nationwide and exported to countries including South Africa, Argentina, Colombia, Australia, America, and Pakistan.

15T/H grass Pellet machine for sale South Africa

A South African agricultural enterprise has procured a 15t/h grass pelletizer. This grass pelleting machine primarily utilizes locally abundant Rhodes grass and corn stalks to produce forage pellets, thereby addressing feed shortages.

3T/H grass Pellet machine for sale Argentina

This Argentine 3-4 t/h grass pellet maker uses 100% alfalfa as raw material to produce high-protein feed pellets specifically designed for feeding high-value livestock such as dairy cows and racehorses.

10T/H grass Pellet machine for sale America

A large U.S. dairy farm procured a 10-12 t/h grass pellet mill to produce high-density feed pellets using a blend of 80% hemp and 20% alfalfa, thereby reducing livestock production costs.

3-4T/H grass Pellet machine for sale Colombia

The 3-4 t/h grass pellet machine purchased by our Colombian client is primarily used for processing cattle feed. The equipment has operated continuously without any issues for two years.

1-2 T/H grass Pellet machine for sale Australia

The Australian 1-2 t/h grass pellet making machine case for agricultural operations uses 50%-80% alfalfa and 20%-50% grains as raw materials to produce feed for ruminants such as cattle and sheep.

2T/H grass Pellet machine for sale Pakistan

The 2 t/h grass pelletizer project in Pakistan utilizes local grasses such as Bermuda grass and sorghum stalks as primary raw materials, supplemented with rice husks, to process agricultural waste into biomass pellet fuel.

Related Videos

RICHI grass pellet machines for sale boast a wide range of applications and have earned consistent praise from customers. You can view videos showcasing two units sold to Argentina and Tajikistan.

The entire process of grass pelleting

The grass pellet machine is only one step in the overall grass pelletization process. The entire pelletization operation is sequential and can be divided into the following four stages. Taking a 6T/H grass combustion pellet production line as an example, the stages are analyzed as follows:

Drying Section

01

Grass-based raw materials typically contain high moisture content and require pre-drying before entering subsequent processing stages to meet pelletization standards.

Grinding Section

02

The grass pellet machine for sale grinds straw materials such as wheat straw and corn stalks to facilitate easy pelletization.

Ingredient Mixing Section

03

Various types of forage and related ingredients are mixed in the mixer to ensure uniform distribution of all raw material components.

Pelletizing Section

04

Material entering the pre-pelletizing chamber is fed through a feeder into the grass pellet machine for sale for double-roll pellet rolling.

Cooling, Screening, and Packaging Section

05

Rolled finished particles are conveyed via bucket elevator into the cooling and screening system. After cooling, the particles are packaged using a packaging scale.

Why Choose RICHI?

RICHI grass pellet machine features a sleek design and international-grade machinery quality, delivering premium performance at a mid-range price.

It empowers you to produce high-quality, ultra-dense, and nutrient-rich forage pellets.

Superior Equipment Quality and Durability

RICHI Machinery‘s grass pellet machine for sale employs high-standard materials and processes, including 304 stainless steel, 40CrMnTi alloy steel, and German vacuum heat treatment, ensuring core components resist corrosion and wear while extending service life by 5–7 times.

Key transmission components feature Siemens motors, imported gearboxes, and Swiss bearings for smoother operation, lower energy consumption, and reduced noise.

Wide Raw Material Adaptability ,Superior Product Quality

RICHI grass pellet machines process diverse forage materials including but not limited to straw, pasture grasses, and crop husks. They excel with challenging raw materials like high-fiber and high-moisture feeds.

The gap between the ring die and press rollers is precisely adjustable via an eccentric shaft, producing pellets with high formation integrity, dense structure, and smooth surfaces.

High Automation, Simple Operation and Maintenance

RICHI grass pellet machines feature variable-frequency feeding, 304 stainless steel conditioning for maturation, and 520 ring die lifters. These designs enable die changes, cleaning, and maintenance to be completed within 10 to 15 minutes.

The entire production line of the grass pellet machine for sale seamlessly integrates with existing data transmission systems, effectively reducing labor costs and downtime while maximizing your profit visualization.

Comprehensive global service network for worry-free after-sales support

With successful deployments in over 130 countries, RICHI offers full lifecycle services for its grass pellet machine for sale, including factory delivery, overseas installation, commissioning, and spare parts supply.

Our 24/7 remote technical support and localized after-sales teams ensure customers can purchase, install, and operate with confidence.

RICHI pledges lifetime technical support, with all mechanical components supplied at cost price.

Frequently Asked Questions

When purchasing a grass pellet machine, you may have many questions. You can refer to the following questions to find answers:

When processing alfalfa straw with 15% moisture content and 25% crude fiber in a grass pellet machine for sale, what compression ratio and die hole size are recommended?

+

For this type of forage material, we recommend a compression ratio of 1:8 to 1:10, with a die hole length-to-diameter ratio of approximately 6mm or 45mm.

Is the 1T/H output instantaneous or continuous?

+

Our continuous operation tests show an hourly output of 600kg–700kg, with an instantaneous capacity of 1 ton.

How many ring dies are included?

+

RICHI’s grass pellet machine for sale comes standard with 1 ring die and 2 bonus roller shells.

What is the starting current for the Grass Pellet Machine? What generator capacity is required?

+

The direct starting current is approximately 6 times the rated current. We recommend a diesel generator rated at 150 kVA or higher.

Can die hole blockages in a grass pellet machine for sale be cleared on-site?

+

Yes. With manual die ejection tools and high-temperature oil, clearing takes about 20 minutes.

What is the warranty period for the Grass Pellet Machine? Are wear parts covered?

+

The grass pellet maker is warranted for 12 months for the entire machine (excluding damage caused by human error), with a 6-month warranty for ring dies and rollers.