10-15T/H Feed Pellet Plant in Uzbekistan

RICHI completed this feed pellet plant in Uzbekistan in October 2020. It covers a total area of 17,500 square meters and took 75 days to build. The client primarily uses it for producing broiler feed.

- Feed Category: Broiler Feed

- Total Cost (USD): 415,000

Background of the Feed Pellet Plant in Uzbekistan

Since 2018, the Uzbek government has encouraged the construction of medium-sized feed mills, promoting the shift of local feed production from small-scale to intensive farming. The feed pellet plant in Uzbekistan was established against this backdrop.

Client Information

When the client contacted us, they were raising approximately 80,000 broilers. They told us they needed a 5-7 tons/hour poultry feed production line.

Our sales representative, after further discussing the matter with the client, discovered that numerous farms in the surrounding area were raising laying hens and broilers.

To maximize the client’s profits, we recommended building a 10-15 t/h animal feed production line. This would allow them to produce approximately 5 tons of feed for their own operations and also meet the feed needs of the surrounding farms.

Production capacity

(tons/hour)

10-15

Pellet size

(mm)

3.5

Customer Needs

After confirming the production volume with the customer, we subsequently conducted a detailed analysis of their breeding scale, raw material characteristics, and equipment requirements for the feed pellet plant in Uzbekistan.

Breeding Needs

A total of 100,000 chickens will be raised. The customer themselves owns approximately 80,000 broilers, and the surrounding scattered farms have a total of approximately 20,000 broilers and laying hens.

Raw Material Needs

Uzbekistan imports 80% of its raw materials, but the customer has a large quantity of wheat on hand locally at their facility, which they can mix with cottonseed meal for poultry feed production.

Equipment Needs

Due to the increased production capacity and the high crude fiber content of the raw materials, the production line equipment must handle large-tonnage feed production and possess good wear resistance.

Core Equipment of the Feed Pellet Plant in Uzbekistan

To better suit the raw materials of our customers’ feed pellet plant in Uzbekistan, we provide hammer mills suitable for processing wheat and cottonseed meal, a 1,000 kg/batch feed mixer, a 110 kW feed pellet mill, as well as coolers, rotary grading screens, and packing scales.

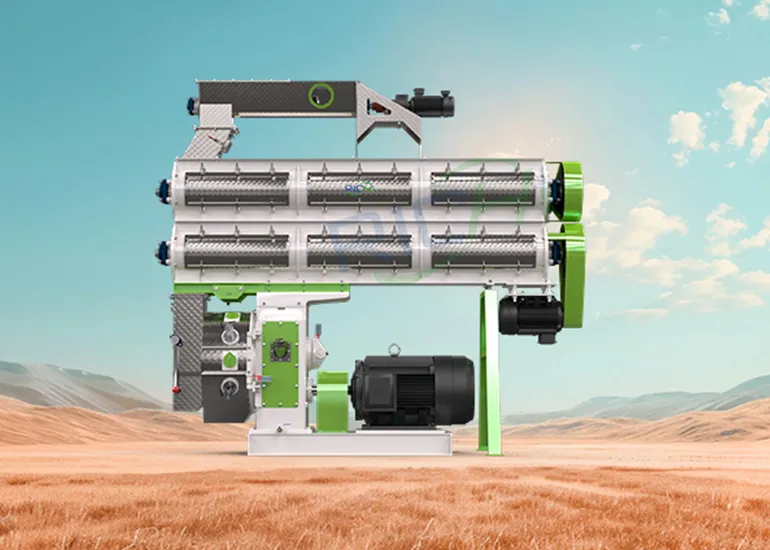

Hammer Mill

The mill employs a two-stage crushing structure, effectively crushing materials smaller than or equal to 5 cm into fine powder suitable for stable pellet production in daily operation.

- Power (kW): 110

- Grain Output (t/h): 10-15

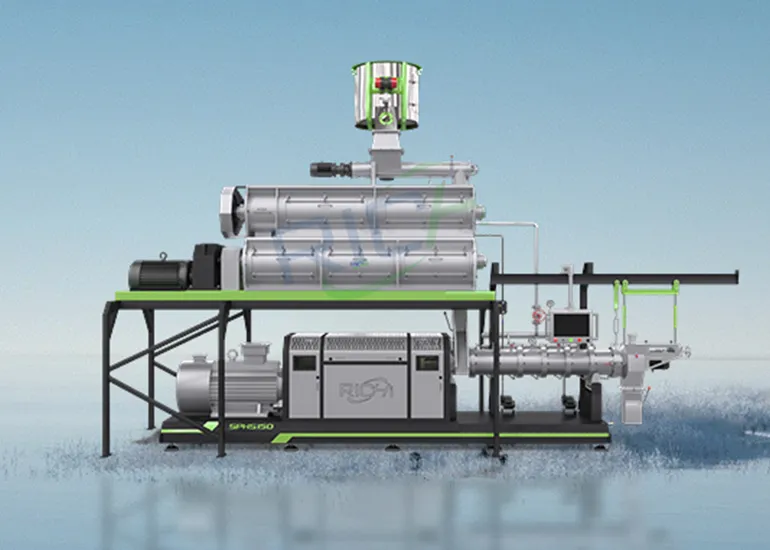

Feed Mixer

Wheat flour has a wide particle size distribution, making it difficult to mix with amino acids, vitamins, etc. As a result, we use a SLHY2.5L mixer for our customers, thereby achieving effective mixing with strong power.

- Power (kW): 18.5

- Mixing Capacity (kg/P): 1000

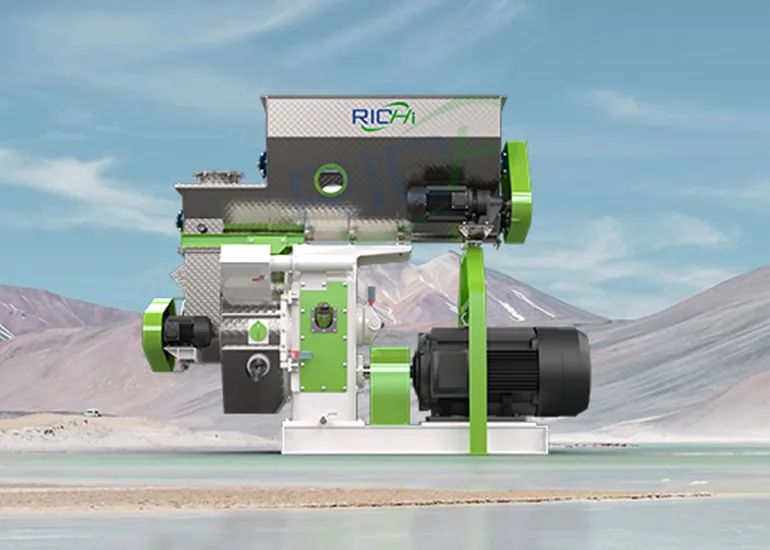

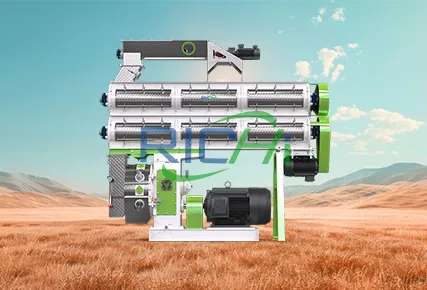

SZLH420 Feed Pellet machine

Designed for the coarse fiber characteristics of cottonseed meal, the SZLH420 animal feed pellet mill uses a variable frequency feeder with gear transmission, making the pelleting process more stable and the pellet quality higher.

- Power (kW): 110

- Output (t/h): 10-15

Cooler

Cools the finished pellets at room temperature after production, thus ensuring higher hardness and a longer storage time for the product.

- Power (kW): 1.5

- Output (t/h): 8-15

Rotary Grading Screen

This equipment can be customized according to your screening needs. The customer customized a two-layer screen to remove powder from the finished pellets.

- Power (kW): 4

- Output (t/h): 8-15

Automatic Packaging Machine

The customer chose our dual-feed packaging system to automatically pack both pellets and crushed feed, meeting broiler farming needs alongside the customer’s primary pellet production.

- Power (kW): 1.5+0.55+0.37

- Output (pkts/min): 6-8

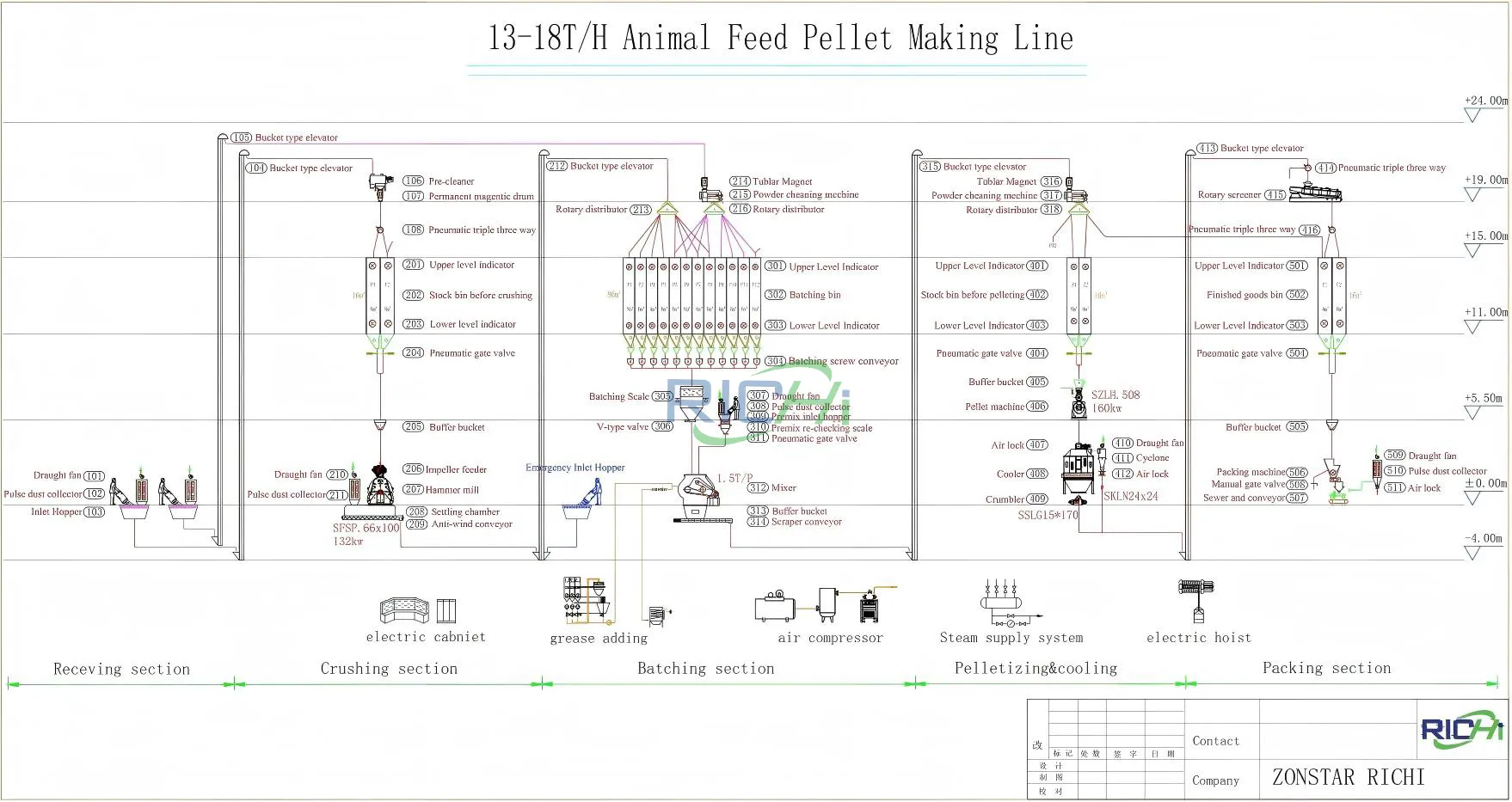

Process Flow of the Feed Pellet Plant in Uzbekistan

Below is a flow chart of the commonly used processes in our 13-18T/H animal feed pellet production line for your reference.

1

Raw Material Processing:

At a feed pellet plant in Uzbekistan, cottonseed meal has a certain degree of toxicity, so the plant must ensure the free gossypol content is no higher than 100-200mg/kg during pre-processing. Regarding wheat, if it is not moldy, the plant only needs to remove impurities during raw material processing. However, if mold has occurred, the plant must conduct relevant tests for aflatoxin, etc.

2

Grinding:

Wheat has a high hardness, and cottonseed meal contains a high amount of crude fiber. Therefore, RICHI, considering the characteristics of the raw materials, ultimately matches customers with hammer mills with stronger grinding power, paired with impeller feeders, allowing the raw materials to enter the grinding chamber more effectively.

3

Secondary Impurity Removal:

At a feed pellet plant in Uzbekistan, pre-impurity removal in the raw material processing stage can only remove most impurities. Secondary impurity removal uses a powder cheaning machine to further refine the impurities from the initial raw materials and the newly added mixed powder.

4

Mixing:

The powdered raw materials that have undergone multiple processing stages are fed into the mixer along with the premix. Specifically, RICHI typically equips its customers with a 1T/H mixer, thereby ensuring excellent mixing performance without additional power consumption.

5

Pelleting:

At a feed pellet plant in Uzbekistan, to ensure a cleaner mixture, RICHI adds tublar magnet and powder cleaning agent before pelleting for a third purification process.

After this third purification, the material enters the SZLH420 feed pellet machine. After a 304 stainless steel temperer heats the material to high temperature, the material enters the pelleting chamber, where alloy steel rollers and ring dies roll it to produce finished pellets.

6

Cooling and Screening:

The high temperature in the pellet mill makes it difficult to directly bag and transport the finished pellets. A cooler is used to lower the pellet temperature to room temperature.

7

Packaging:

Before packaging, the cooled pellets first undergo four screenings. Specifically, the primary purpose of this screening is to remove broken material generated during conveying, thereby ensuring a uniform pellet size and superior quality.

Following this, the screened pellets are then conveyed to a fully automatic packaging machine for packaging.

Note:

To protect client information, we cannot display the detailed process design drawings for this project. This is only a common flowchart we design. For a specific design, RICHI will provide you with precise one-on-one customization until you are satisfied.

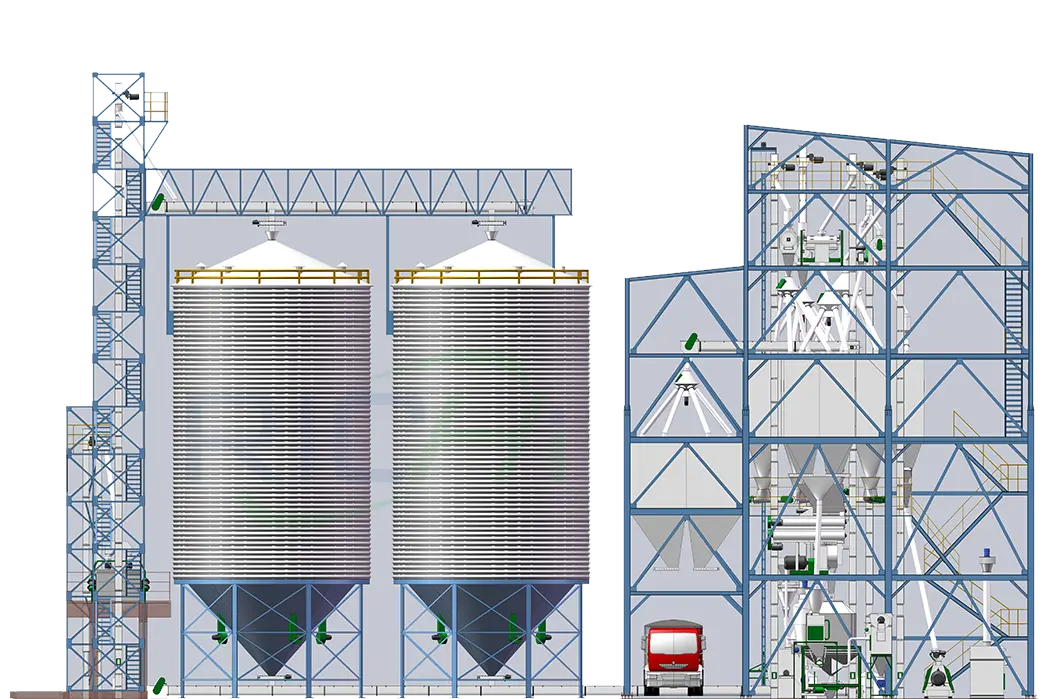

Construction Process of the Feed Pellet Plant in Uzbekistan

The construction process for a 10-15T/H feed pellet plant in Uzbekistan essentially includes what we typically call civil engineering, equipment installation and commissioning, as well as preliminary consultation, and importantly, subsequent training and technical support.

Preliminary Consultation

01

The client initially contacted us through our website form. After our consultants confirmed the initial production capacity and machinery, a professional sales representative then handled the detailed process coordination.

Process Design

02

Notably, throughout the process design process, RICHI’s sales representatives and engineers consulted with the client multiple times and subsequently made reasonable modifications, ultimately determining the accurate process flow for construction implementation.

Equipment Production and Logistics

03

After finalizing the process flow with the client, we will then schedule production at our own factory to ensure that the construction equipment is produced for the client as quickly as possible, thereby avoiding delays to the client’s project schedule.

Civil Engineering Construction

04

RICHI can contract for civil engineering construction. However, in this project, due to the pandemic, the client chose to use their own construction team for civil engineering, while RICHI engineers provided remote guidance throughout the process.

Installation and Commissioning

05

After the entire project is completed, RICHI engineers will conduct operational commissioning to ensure that both the core pelleting equipment and auxiliary conveying equipment in the entire production line achieve the customer’s most satisfactory pelleting results.

Production Training

06

Specifically, equipment installation and commissioning are core steps in our construction process. In the next phase, we will train the customer’s employees on the feed pelleting production process.

Furthermore, we will provide detailed explanations to maintenance workers on how to perform post-production maintenance of the machinery to ensure a longer service life for the production line.

Acceptance and Commissioning

07

With all preliminary preparations complete, the customer can begin daily production. Any problems encountered during production can be addressed by the customer through online support within 24 hours.

RICHI services

In this feed pellet plant in Uzbekistan, RICHI provided clients with dedicated consultation, production line design and construction, and ongoing commissioning and technical update support.

RICHI currently operates 24 feed production projects in Uzbekistan, covering regions such as Tashkent, Samarkand, Fergana, and Urgench.

Brand Advantages

We are never worried about your questions, as our extensive experience allows us to provide the most satisfactory solutions.

Client Testimonial: “We are very grateful for RICHI’s patient guidance and continuous optimization throughout the process, which enabled our project to be completed smoothly. Furthermore, all the equipment is now running steadily, the whole process was very smooth, and as a result, it has brought more profits to our farm!”

Customized Solution for the Feed Pellet Plant in Uzbekistan

This 10-15T/H feed pellet plant in Uzbekistan was built during the pandemic, a challenging task for any construction company. Numerous problems arose during construction, but RICHI, leveraging its experience from thousands of projects, resolved all issues.

Solving Complex Problems with a Systems Engineering Approach

Problem: Uzbekistan experiences summer temperatures reaching 40°C and cold winters, with significant diurnal temperature variations across the region.

Customized Solution: When designing this project for the client, RICHI employed a systems thinking approach, considering the equipment integration within the overall construction and operation of the pellet plant.

High-temperature resistant models were used for motors, gearboxes, and other components, and the entire workshop design was optimized for heat dissipation and ventilation.

Customized Equipment Supply Solution

Problem: The 2020 pandemic disrupted global logistics, hindering the dispatch of technical personnel.

Customized Solution: After extensive discussions with the client, RICHI ultimately decided to prioritize the delivery of several core pieces of equipment, including pellet mills, crushers, mixers, coolers, and baling scales.

For common construction components such as steel frames and pipes, the option is to have the client purchase them locally or in neighboring countries to minimize waste.

Customized Raw Material Proportioning Solution

Problem: The client’s cottonseed meal had a high crude fiber content, and the wheat had high hardness, posing significant processing challenges during pelleting.

Customized Solution: RICHI designed a coarse crushing line for the client, coupled with fine crushing equipment for double crushing. An arch-breaking feeder and a forced feeder were added to the core pelleting equipment, ensuring a smoother pelleting process.

Why Choose RICH?

RICHI Machinery is a professional manufacturer and trader of feed production equipment and biomass pellet production equipment in China.

We not only focus on equipment manufacturing, but also on building faster and higher-quality feed production lines and biomass pellet production lines.

Customized Solutions

We always put our customers first. Specifically, we design specialized production equipment and carefully tailored engineering lines that ultimately better suit their very unique needs and truly diverse requirements.

High-Performance Production

RICHI specifically uses unibody forged steel, 304 stainless steel, and high-durability alloy steel in the production of core equipment, thereby allowing you to purchase cost-effective pelletizing equipment at lowest price.

Quality Service

Specifically, from consultation to after-sales service, we have established a one-stop service system. Ultimately, 30 years of continuous refinement are all aimed at providing you with a better service experience.

1

How to efficiently process cottonseed meal and wheat from feed raw materials in Uzbekistan?

Specifically, cottonseed meal processing primarily involves reducing toxicity, typically achieved through precise formulation with ferrous sulfate. Additionally, for wheat, xylanase is used to reduce stickiness and increase feed digestibility.

2

Given the hot summers in Uzbekistan, what special designs are needed for the plant and equipment?

Plant design focuses on ventilation. Specifically, roofs are typically insulated, and large air exchange systems are usually installed on the sides. For equipment, high-temperature-resistant components such as motors, PLCs, and sensors need to be selected.

3

What is the total investment for a 10-15T/H feed pellet plant in Uzbekistan? What is the payback period?

Based on our experience, the total investment, including equipment, civil engineering, and subsequent operation, is generally between US$800,000 and US$1,250,000. The investment return cycle is generally 3-4 years, but the specific timeframe depends on your raw material input and subsequent market investment.

4

My factory workers lack technical experience. How will the factory operation and equipment maintenance be handled later?

Choosing RICHI means choosing a one-stop service. Specifically, for your feed pellet plant in Uzbekistan, RICHI will provide ongoing equipment maintenance and pellet production training for your factory workers, thereby ensuring a smooth and orderly feed production process.

We also promise to provide permanent technical support for our production equipment.

5

What are the sales channels and market competition like for feed produced by feed pellet plant in Uzbekistan?

In Uzbekistan, government support for medium and large-sized feed mills has led to a trend of centralization in local feed production. Furthermore, the high demand for feed in the region means numerous sales channels, including local farms and agricultural cooperatives.

The entire feed market in Uzbekistan is gradually becoming more standardized, which also means fierce price competition. To break through in this environment, you need higher-quality and more stable finished feed products, as well as more innovative technical services.

RICHI can fully meet your needs. You can also watch related videos on YouTube.

RICHI Machinery

RICHI Machinery has established over 2,000 production projects worldwide and sold over 10,000 units of equipment. Its on-time delivery rate reaches 98.5%, and customer satisfaction is as high as 98%.

About RICHI

As an international equipment manufacturer with 30 years of industry expertise, we deliver turnkey solutions for fully automated pellet production lines ranging from 1 to 100 tons per hour.

Established in 1995

Dedicated to granulation equipment R&D

ATEX | CE | ISO | SGS Certified Quality

RICHI Business Scope

RICHI Machinery has over 200 employees and a production area of over 340 acres.

Since its establishment in 1995, RICHI Machinery has expanded its business footprint to 140 countries and regions worldwide, with deep-rooted operations across six continents: Asia, Europe, North America, South America, Africa, and Oceania.