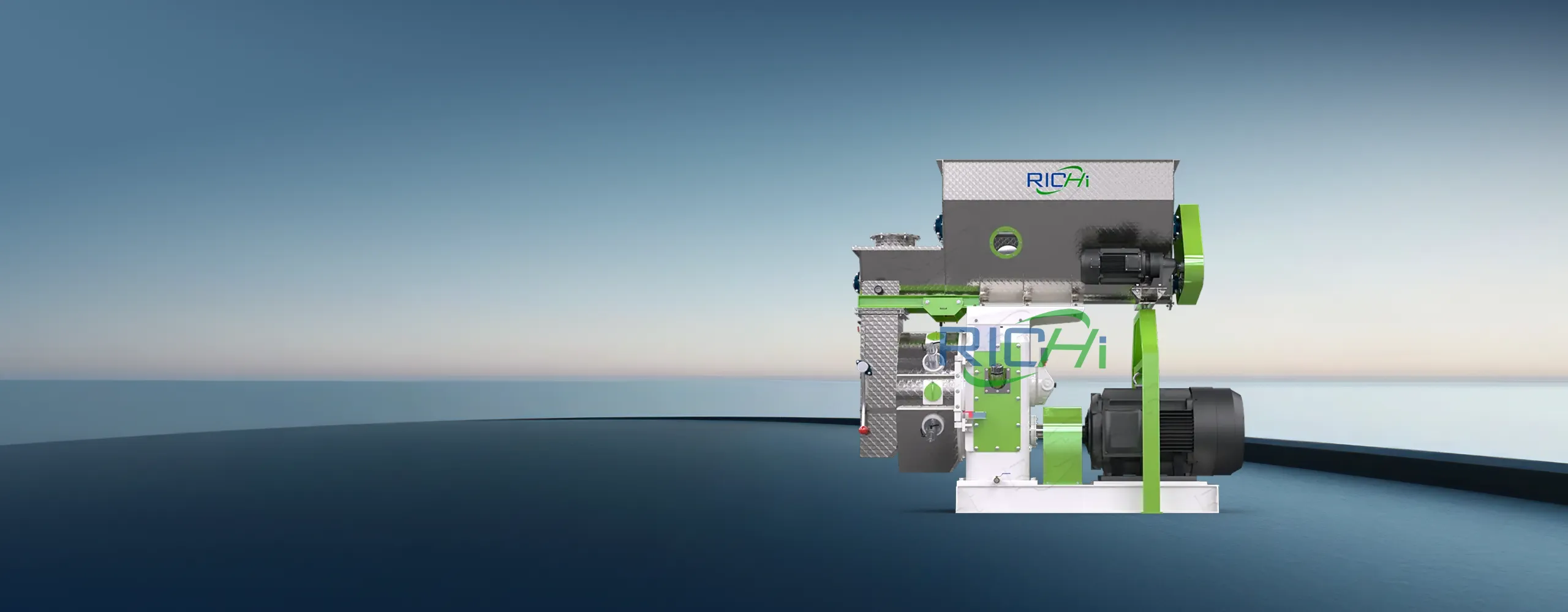

EFB Pellet Machine

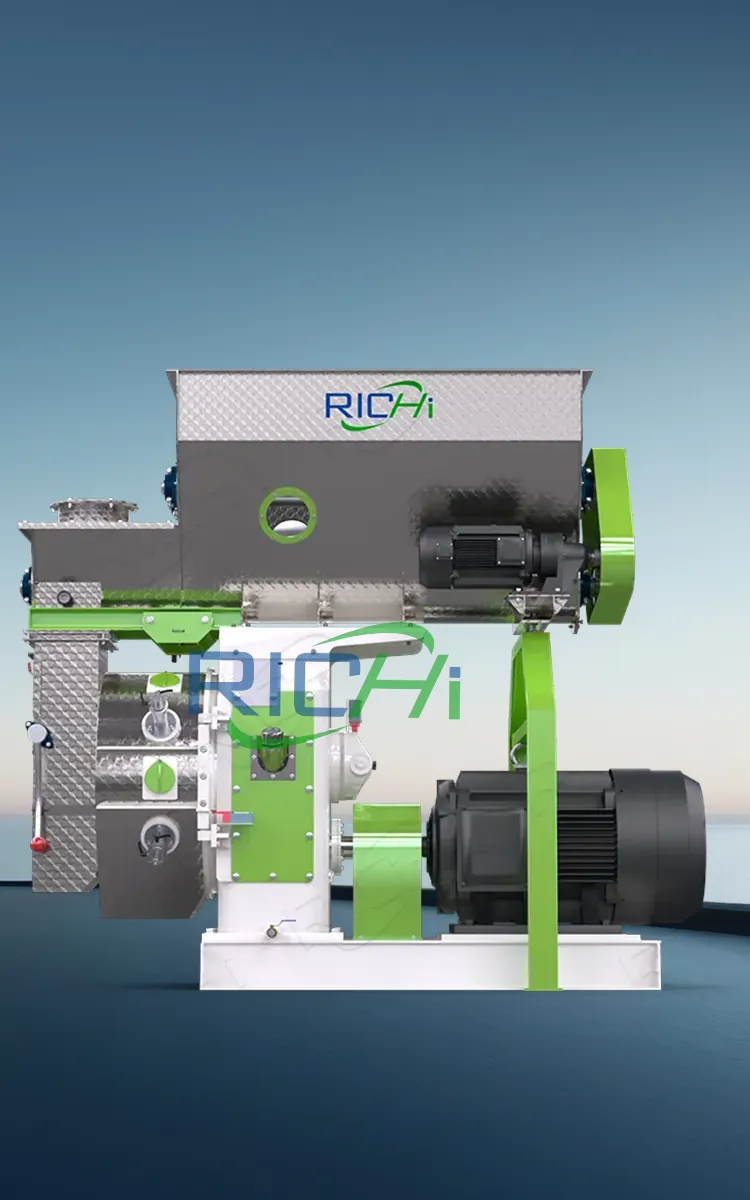

The structure composition of EFB pellet mill

The overall structure of the EFB Pellet Machine comprises five major systems: the feeding system, transmission system, pelleting system, lubrication system, and safety overload protection system.

A detailed component breakdown of the EFB pellet making machine is as follows:

Feeding System

Transmission System

forced feeder

pelletizing chamber

cutter

Siemens motor

Through years of technological iterations, we have developed heavy-duty, wear-resistant, and high-efficiency EFB pellet machines to ensure smoother and more stable operation for our customers.

EFB Pellet Machine Model

The EFB pellet machine is not only suitable for empty fruit bunches, but also for palm fiber, palm shells, and various agricultural and forestry waste materials.

RICHI meticulously designs pellet mills with different capacities and power ratings, offering you a wide range of options.

| EFB Pellet Machine | ||||||

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Main Motor Power (KW) | 22 | 37 | 90 | 132 | 185 | 250 |

| Arch-Breaking Feeder Power (kW) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power (kW) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Inner diameter of ring mold (mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished Particle Diameter (mm) | 4~12 | |||||

| Output(T/H) | 0.2-0.3 | 0.3-0.5 | 1.0-1.2 | 1.5-2.0 | 2.5-3.0 | 3.0-4.0 |

Test Run Video of EFB Pellet Machine

Working Principle

When the pre-processed EFB (Empty Fruit Bunch) raw material enters the variable frequency feeder of the EFB pellet machine, the twin shafts in the feeder rotate in opposite directions to break up the highly fibrous, tangled raw material.

After being mixed by the long-axis agitator, the material falls vertically into the feeding trough and is then pushed by a forced feeder into the pelletizing chamber for pelletization.

The pelletizing chamber uses a highly wear-resistant ring die and other components, allowing the raw material to be transformed into finished pellets under high pressure. The finished material then falls out through the discharge opening at the bottom.

Key Technology Of EFB Pellet Machine

Frequency-Controlled Feeding System — Effectively Eliminating Fiber Entanglement

EFB (Empty Fruit Bunch) itself contains approximately 65%-75% fiber by dry weight, which easily leads to entanglement and blockage during feeding, potentially causing machine idling and shutdowns.

RICHI EFB pellet machines, equipped with a variable-frequency feeding system and using differential-diameter twin-shaft anti-bridging rollers for breaking and mixing, effectively disentangle the material and better solve the problem of fiber entanglement.

Expanded Pelleting Chamber — Accommodating High-Volume Fluffy EFB Material

EFB raw material has a porous structure and is fluffy, resulting in low output per batch when using ordinary pelletizing machines, which leads to poor economic efficiency.

The RICHI EFB pellet machine utilizes a larger capacity pelletizing chamber, improving the efficiency of each batch and resulting in higher output and greater economic benefits.

42CrMo Rollers — Overcoming Severe Wear Challenges

EFB fibers contain silica from palm trees, which results in higher hardness and greater abrasiveness, placing higher demands on the ring die, press rollers, and cutting tools of the pellet mill.

EFB pellet machines utilize harder 42CrMo press rollers and 520 ring dies, coupled with an 8P main motor drive, significantly improving wear resistance and traction.

Features and Advantages of EFB Pellet Machines

High Adaptability

The RICHI EFB pellet machine is suitable for a variety of biomass and agricultural waste materials, including but not limited to empty fruit bunches, palm shells, palm fibers, rice husks, and branches, without requiring frequent changes.

Superior Wear Resistance

Conventional press rollers cannot meet the granulation requirements of EFB. RICHI EFB pellet mill press rollers utilize high-quality chromium alloy steel and a technical process with interconnected left and right sides and narrow shell gaps, making the entire pressing process more efficient and less labor-intensive.

Faster Return on Investment

RICHI EFB pellet machines utilize the highest quality Chinese components and exclusive manufacturing processes to the greatest extent possible. This ensures that the pellet mills fully meet production requirements while reducing initial investment costs and subsequent operating costs.

Related cases of EFB Pellet Machines

Due to their high wear resistance and strong practicality, RICHI EFB pellet machines have been sold to countries such as Malaysia, Indonesia, Thailand, and Colombia. Below are six real-world case studies from our company.

4 T/H EFB pellet machine for sale Malaysia

Processing fresh empty fruit bunches into high-density fuel pellets for local energy use and export to markets like Japan and South Korea.

- Output (t/h) : 4

- Power (kw) : 250

- Pellet Diameter (mm) : 4

2 T/H EFB Pellet Machine For Sale Indonesia

Producing biomass fuel from empty fruit bunches and palm shells for power generation and industrial boiler applications.

- Output (t/h) :2

- Power (kw) :185

- Pellet Diameter (mm) : 8

3-5 T/H EFB Pellet Mill For Sale Colombia

Converting EFB and coffee husks into organic fertilizer to support sustainable agriculture and local green farming initiatives.

- Output (t/h) : 3-5

- Power (kw) : 250

- Pellet Diameter (mm) : 4-6

8 T/H EFB pellet making machine in Thailand

Processing mixed raw materials including empty fruit bunches, bagasse, and wood chips for ruminant feed and biomass fuel production.

- Output (t/h) : 8

- Power (kw) : 132 × 4

- Pellet Diameter (mm) : 8-12

1.5-2.5 T/H EFB Pellet mill For Sale Philippines

Producing high-quality boiler fuel and barbecue charcoal materials from crushed, blended empty fruit bunches and coconut shell fiber.

- Output (t/h) : 1.5-2.5

- Power (kw) : 185

- Pellet Diameter (mm) : 8-12

2-3.5 T/H EFB pelleting machine in Nigeria

Generating cost-effective power fuel from empty fruit bunches mixed with corn stalks to address local electricity challenges.

- Output (t/h) : 2-3.5

- Power (kw) : 132

- Pellet Diameter (mm) : 4-6

Related Videos

EFB pellet mills have a wide range of applications, such as in large and medium-sized palm oil mills, feed mills, fuel plants, and fertilizer plants.

Customers in Peru use our pellet machines to produce animal feed, while Malaysian customers primarily use the EFB pellet machines to make fuel pellets. In Thailand, customers who purchase our EFB pelletizer machines use them to produce organic fertilizer for sale.

The entire Process of EFB Pellet Production

In Southeast Asian countries, EFB (Empty Fruit Bunch) is readily available and inexpensive, and the resulting pellets have a wide range of applications.

However, an EFB pellet machine alone may not always meet your needs. The overall EFB pelletizing process is specifically divided into the following six stages:

Crushing

01

With long fibers, empty fruit bunches require initial crushing into 5-10 cm pieces by a shredder. Next, a chipper further shreds the bunches into a powder-like texture, which supports the subsequent granulation process.

Impurity Removal

02

Raw materials usually contain various impurities, such as iron particles and dust. To boost raw material purity and prevent machinery damage from foreign matter, impurity removal equipment processes the crushed particles and eliminates these impurities.

Drying

03

Empty fruit bunches typically have a moisture content of 60%-70%, making them quite wet and unsuitable for pelletizing. Therefore, a drying system is required to dry them.

Carbonization

04

In this process, a carbonization furnace is used to pyrolyze the dried EFB fibers, converting them into biochar. This results in higher density and greater hardness of the granules during the subsequent pelletizing process.

Pelleting

05

After the pre-processed materials enter the pelletizing chamber of the EFB pellet machine, double rollers roll them to produce finished pellets with a diameter of 6-10mm, and these pellets boast higher calorific value and nutritional value.

Cooling

06

Granules from the EFB granulation machine have elevated temperature and inadequate hardness, and a cooler reduces their temperature to room temperature for subsequent long-term storage.

Packaging

07

RICHI designs and manufactures automated packaging systems, allowing you to choose the packaging method that best suits your needs for packaging and selling your finished granular products.

Why Choose RICHI?

RICHI Machinery is a leading representative of China’s high-end machinery industry. For many years, we have been committed to breaking down technological barriers in granulation technology, continuously developing and manufacturing granulation equipment of higher quality, superior craftsmanship, and better suited to customer needs.

Brand Credibility

RICHI Machinery has been dedicated to pelletizing equipment for 30 years, meticulously developing high-end EFB pellet mills that are better suited for high-fiber and abrasive raw materials. This allows you to receive superior, customized service and a better pelletizing experience at a lower price.

Precision Manufacturing

RICHI EFB pellet machines utilize a differentiated, targeted approach in overall material selection. The core pelletizing system employs more wear-resistant high-chromium alloy steel and a higher-hardness carburizing and quenching process, resulting in a superior, cost-effective EFB pellet mill.

Superior Product Performance

EFB contains high levels of potassium, oil, fiber, and calories. When processed with an EFB pelletizing machine, it can be transformed into animal feed with higher nutritional content, fuel pellets with improved combustion properties, and organic fertilizer with a higher potassium content.

Frequently Asked Questions

Choosing the right EFB pellet machine in today’s market is not an easy task. It requires considering various factors such as cost investment, machine quality, raw material compatibility, and long-term operation and maintenance.

The answers to the following frequently asked questions may provide you with some guidance.

Regarding the high abrasiveness of EFB fibers, what specific materials and heat treatment processes are used for the ring die and rollers of your EFB pellet machines to ensure durability? How is wear resistance verified?

+

RICHI EFB pellet mills utilize ring dies and rollers made with a bimetallic composite process. The ring die material is 42CrMo, and we will provide a third-party material testing report. We also support you in sending raw material samples to our testing center for wear comparison testing.For more details, you can also watch the relevant videos on the YouTube platform.

My EFB raw material has a moisture content of 65%. How does your system handle the drying process, and what is the most cost-effective solution for the heat source?

+

RICHI provides integrated solutions based on thermal energy cycles. We offer single-channel or three-channel rotary dryers as standard equipment, better suited to the long fiber structure of EFB.

Furthermore, for an economical solution regarding the heat source, we primarily utilize steam from a boiler to generate hot air through a heat exchanger, and we also install fire extinguishers at the front end of the boiler to prevent safety hazards.

We aim to produce not only standard pellets for industrial boilers but also high-quality pellets (such as ENplus-certified) for export. Can your machines achieve this?

+

RICHI can fully meet your requirements. The main differences between the export-grade pellets you need and ordinary pellets lie in purity, ash content, and mechanical pressing effect. We will add impurity removal and screening devices at various stages of the process.

Furthermore, our EFB pellet mill uses superior pressing components, ensuring that your raw materials are purer and the resulting pellets are of higher quality.

EFB from different regions, tree ages, and processing methods may vary in fiber characteristics. How does your EFB pellet machine adapt to such fluctuations through adjustable mechanical settings, rather than solely relying on changing the ring die?

+

Our roller system is equipped with a hydraulic servo adjustment mechanism, allowing real-time fine-tuning of the roller-ring die gap during operation.

This adaptive design enables the machine to effectively process EFB fibers with varying elasticity and oil content without the need for frequent ring die replacement.

EFB raw materials inevitably contain small amounts of sand, stones, or even metal impurities. How does your system protect the core components of the EFB pellet machine from damage through step-by-step and effective measures?

+

Throughout the EFB pellet production line, we integrate a multi-stage, progressive impurity removal system. For example, after initial weighing, magnetic separators are installed on conveyor belts to remove ferrous contaminants at close range.

Following the crushing stage, pulse dust collectors and cyclones are deployed for secondary impurity removal, ensuring comprehensive protection of the machine’s core components.