Biomass Pellet Production Line

A biomass pellet production line utilizes a series of integrated equipment to transform various agricultural and forestry biomass waste materials into high-quality pellets with strong combustibility and excellent storage properties.

RICHI biomass pellet production lines are dedicated to providing you with more professional biomass pellet manufacturing solutions.

- Production Capacity (T/H): 0.5-40

- Price (USD): 50,000-3,000,000

RICHI 0.5-40 TPH Biomass Pellet Production Line

RICHI biomass pellet production lines have a capacity ranging from 0.5 to 40 tons per hour, meeting the production needs of small, medium, and large-scale operations.

Investment and Return on Investment of RICHI Biomass Pellet Production Lines

The investment price of a RICHI biomass pellet production line generally ranges from US$50,000 to US$3,000,000. The specific cost depends on your raw materials, production capacity, investment budget, and other operating costs.

Based on our experience, the return on investment period for most plants is approximately 2-3 years. Our Polish customer purchased a 3-4 T/H wood pellet production line, and the return on investment period was about 2 years; our Argentinian customer purchased a 4-5 T/H alfalfa pellet production line, and due to low transportation costs, the entire payback period was only one and a half years, etc.

If you have any inquiries, please feel free to contact us.

Finished pellet molding rate

98%

Pellet size

2-12mm

Types of Biomass Pellet Production Lines

Biomass pellet production lines can process all types of biomass raw materials, including agricultural wood waste such as sawdust, wood chips, and branches; agricultural residues such as straw, forage grass, rice husks, alfalfa, and EFB; as well as organic fertilizers and animal manure.

Wood pellet

grass pellet

Rice husk pellet

Alfalfa pellet

EFB pellet

Organic fertilizer

Workflow of Biomass Pellet Production Line

RICHI biomass pellet production lines boast a molding rate of over 98%, with any substandard crushed material being processed by the equipment and entering a new granulation cycle.

The entire process is not complicated, consisting of six stages: raw material processing, crushing, drying, granulation, cooling and screening, and packaging.

Raw Material Processing

01

Whether it’s branches, furniture scraps, straw, crop husks, or even animal manure, all raw materials require initial processing to remove impurities, especially iron objects.

Crushing

02

To ensure a smooth and high-quality granulation process, the biomass raw materials, after impurity removal, need to be properly crushed by a crusher.

Drying

03

The moisture content of the raw materials before granulation is usually between 12% and 18%. If your raw materials already have a moisture content within this range, drying is not necessary. Otherwise, a drying stage is required.

Granulation

04

This is the core stage of biomass pellet production. In this stage, the powdered raw materials are processed into compact pellets in a high-temperature, high-pressure environment within the granulation chamber.

Cooling and Screening

05

The finished pellets may experience collisions during transportation between stages, and due to the high temperature, the finished pellets may not be hard enough. A cooler is needed for cooling, and broken pieces are screened out.

Packaging

06

The processed pellets fully meet the requirements for finished product sales. Therefore, proper packaging is necessary for better transportation and storage of the finished pellets.

Equipment for Biomass Pellet Production Line

The ability of a biomass pellet production line to process a wider variety of raw materials and its overall lifespan depend on the quality of the complete set of equipment. RICHI meticulously crafts a complete set of production equipment, providing you with the most cost-effective pelletizing experience.

Template Crusher

Can crush various types of wood products with nails into 2-4cm wood chips.

- Equipment Name :Template Crusher

- Main Motor Power :75 – 220 kW

- Power :1.1-2.2KW

More →

Hammer Mill

Can be used to crush various biomass raw materials, including agricultural and forestry waste.

- Equipment Name:Hammer Mill

- Capacity :50L/Min

- Power :30KW-110KW

More →

Forage Crusher

Specifically designed to crush forage raw materials into 0.5-20mm.

- Equipment Name :Forage Crusher

- Capacity :0.5 kW

- Power :22KW

More →

Conveying Equipment

Conveying equipment is an important tool connecting two stages, ensuring perfect transportation of raw materials.

- Equipment Name :Screw Conveyor

- Capacity :8–80 m³/h

- Screw Diameter :160–400 mm

More →

Drum Dryer

Dries raw materials with high moisture content to ensure higher pellet quality.

- Equipment Name : Drum Dryer

- Rotation Speed :3 – 12 rpm

More →

Pellet machine

RICHI has developed several biomass pellet mills, including wood chip pellet mills, forage pellet mills, cat litter pellet mills, and organic fertilizer pellet mills.

- Equipment Name :Biomass Pellet Machine

- Output :0.5 – 4 T/H

- Power :22-250KW

More →

Cooler

Cools the finished pellets to room temperature for easy storage.

- Equipment Name :Cooler

- Output :1 -40 T/H

- Power :1.5 – 2.2 KW

More →

Rotary Grading Screen

Screens the finished pellets into different specifications.

- Equipment Name :Rotary Grading Screen

- Output :2 – 50 T/H

- Power :0.18 – 0.55 kW

More →

Packaging Scale & Heat Sealer

RICHI offers packaging scales with capacities ranging from 10 to 50 kg for you to choose from.

- Equipment Name :Packaging Scale & Heat Sealer

- Output :2–8 bags/min

More →

Video of Biomass Pellet Production Line

RICHI biomass pellet production lines are designed on a one-to-one basis according to customer needs.

Below are examples of biomass pellet production lines we have designed for our clients: a line for processing waste, clothing fibers, and plastic raw materials; a sawdust pellet production line for a client in Bangladesh; an alfalfa pellet production line for a client in Argentina; and a clay pellet production line for a client in Canada.

Biomass Pellet Production Line Projects

RICHI has built over 500 biomass pellet production projects, covering more than 60 countries worldwide, including Canada, Argentina, the United States, the Netherlands, Russia, South Africa, Senegal, and Bangladesh.

6-8T/H Biomass Pellet Production Line in Senegal

The client runs an agricultural company locally and has abundant peanut shell resources. When they contacted us, the client already had a 3-ton peanut shell production line. The subsequent expansion was due to the client expanding their resources to include other raw materials such as wood chips and straw.

- Project Construction Period (days): 25

- Total Project Cost (USD): 450,000

20T/H Biomass Pellet Production Line in Bangladesh

This is a bamboo and wood pellet biomass production line. The client has abundant bamboo forest resources locally. To expand the production line to meet production needs, the client contacted us hoping that we could build a new biomass pellet production line for them.

- Project Construction Period (days): 80

- Total Project Cost (USD): 1,050,000

4T/H Biomass Pellet Production Line in Canada

This is our first clay pelletizing project built in Canada. The client’s region has abundant bentonite resources, and he wanted to use clay to produce cat litter and other pet supplies. We specifically designed a clay biomass pellet production line for him.

- Project Construction Period (days): 30

- Total Project Cost (USD): 320,000

5T/H Biomass Pellet Production Line in the Netherlands

This is a biomass pellet production line primarily using miscanthus and switchgrass as raw materials. The client also purchases low-quality grass materials such as straw from surrounding farms to mix and produce biomass pellets. Based on the client’s needs, we specifically designed a production line equipped with drying equipment.

- Project Construction Period (days): 60

- Total Project Cost (USD): 380,000

10T/H Biomass Pellet Production Line in the USA

The client has reached long-term agreements with several local sawmills and plywood factories. He told us that he needed a dedicated biomass pellet production line to produce wood pellets. The raw materials mainly consist of sawdust, wood scraps, and small-diameter timber.

- Project Construction Period (days): 85

- Total Project Cost (USD): 750,000

2-3T/H Biomass Pellet Production Line in Russia

The client owns a medium-sized sunflower oil company locally. Approximately 41 tons of sunflower hulls are produced daily, and traditional landfill disposal was strictly prohibited locally after 2019. The client contacted us hoping to build a suitable biomass pellet production line.

- Project Construction Period (days): 30

- Total Project Cost (USD): 250,000

1.5T/H Biomass Pellet Production Line in South Africa

A local agricultural cooperative contacted us, stating their need to build a straw biomass pellet production line. The raw materials mainly consist of corn stalks and wheat straw, which they want to process into biomass pellets for sale.

- Project Construction Period (days): 40

- Total Project Cost (USD): 150,000

3-4 T/H Biomass Pellet Production Line in Argentina

Argentina’s climate is ideal for alfalfa growth, and the client is a local farmer. He wanted to process alfalfa into high-quality biomass fuel pellets for export. Based on his raw material output, we built a biomass pellet production line for him in Argentina.

- Project Construction Period (days): 25

- Total Project Cost (USD): 300,000

2T/H Biomass Pellet Production Line in Canada

This wood processing plant uses sawdust and wood chips as raw materials. Given the raw materials’ moisture content exceeding 50%, we designed a customized biomass pellet production line for the client, complete with drying equipment.

- Project Construction Period (days): 45

- Total Project Cost (USD): 195,000

RICHI Footprint

NORTH AMERICA

EUROPE

SOUTH AMERICA

AFRICA

ASIA

OCEANIA

The Future of Biomass Pellet Production Lines

In our 30 years of dedicated research and development of biomass pellet production equipment, the construction of biomass pellet production lines has become an inevitable trend.

The introduction of global national environmental protection policies has increased the demand for production lines from local farms, furniture factories, agricultural enterprises, and forestry owners. Simultaneously, it has opened up new development opportunities for local fuel supply.

A Promising Future

The business model of biomass pellet production lines is undergoing a substantial transformation. Biomass pellet producers are no longer selling fuel piecemeal, but are signing long-term cooperation agreements with heating users to increase the stability of the industry.

RICHI, focusing on the innovation and manufacturing of complete biomass pellet production equipment, is your most professional pellet manufacturing partner.

Customized Biomass Pellet Line

What capacity biomass pellet production line do you need? RICHI biomass pellet production lines cover small, medium, large, and extra-large production scales, providing you with customized pelleting options.

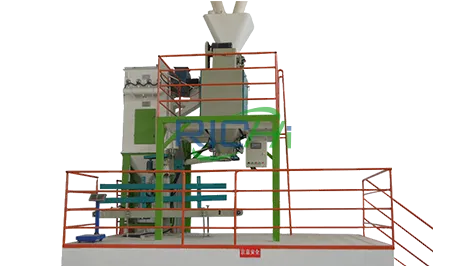

Customized Process Flow Demonstration

— Richi Machinery —

Below are partial process flow diagrams designed by RIHCHI. Each process includes six stages: raw material processing, crushing, drying, pelletizing, cooling and screening, and packaging.

The main equipment used in the flow diagrams includes, but is not limited to: drum chipper, drop mill, dryer, MZLH420 pelletizer, cooler, and standard packaging scale.

Of course, the following flow diagrams represent only the most common type. If you require a more customized design, please contact us for one-on-one customization.

1-1.2TPH Biomass Pellet Production Line Flow Diagram

This is a small, disconnected production line flow diagram. Its overall advantage lies in its lower price and ease of individual processing at each stage.

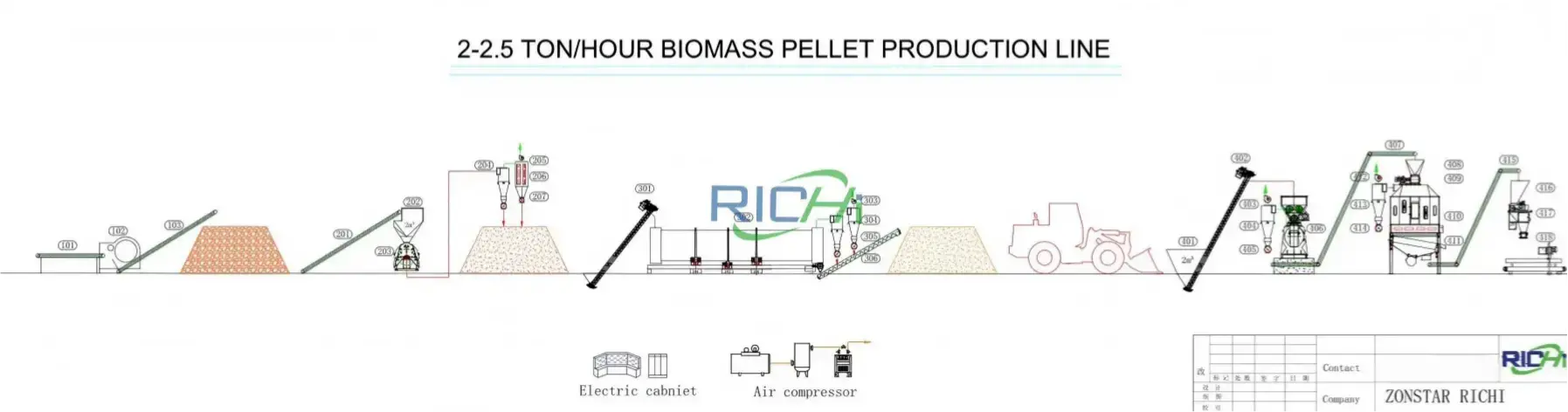

2-2.5TPH Biomass Pellet Production Line Flow Diagram

The drum chipper in the flow diagram can be selected based on your raw material requirements; it is not a mandatory piece of equipment.

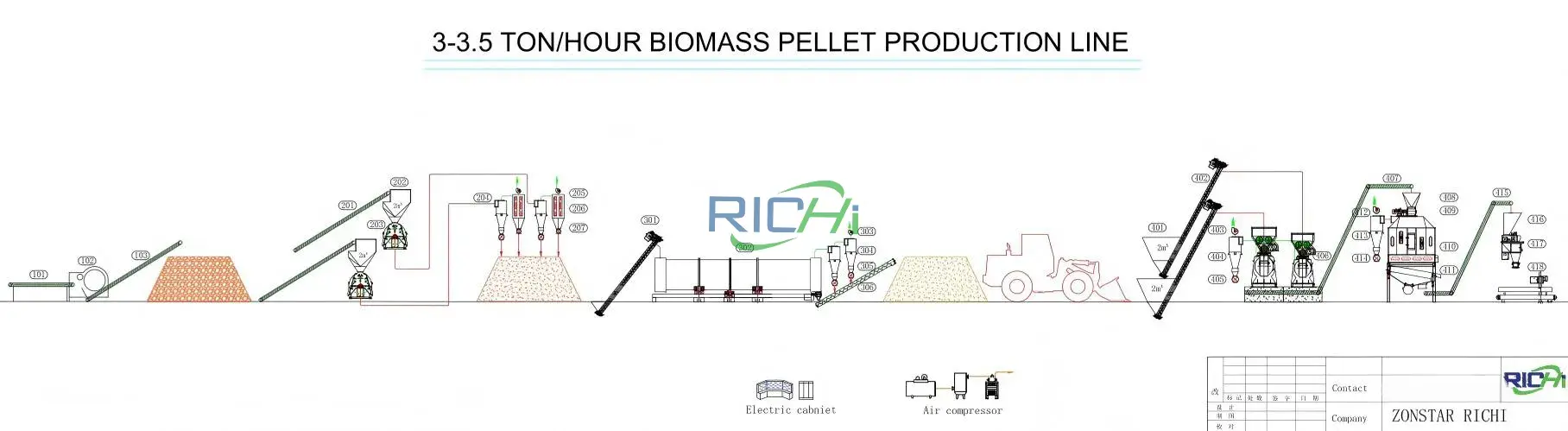

3-3.5TPH Biomass Pellet Production Line Flow Diagram

To achieve more efficient processing, we have added two crushers and pelletizers to the process, and also equipped the subsequent transportation stage with two conveyor systems.

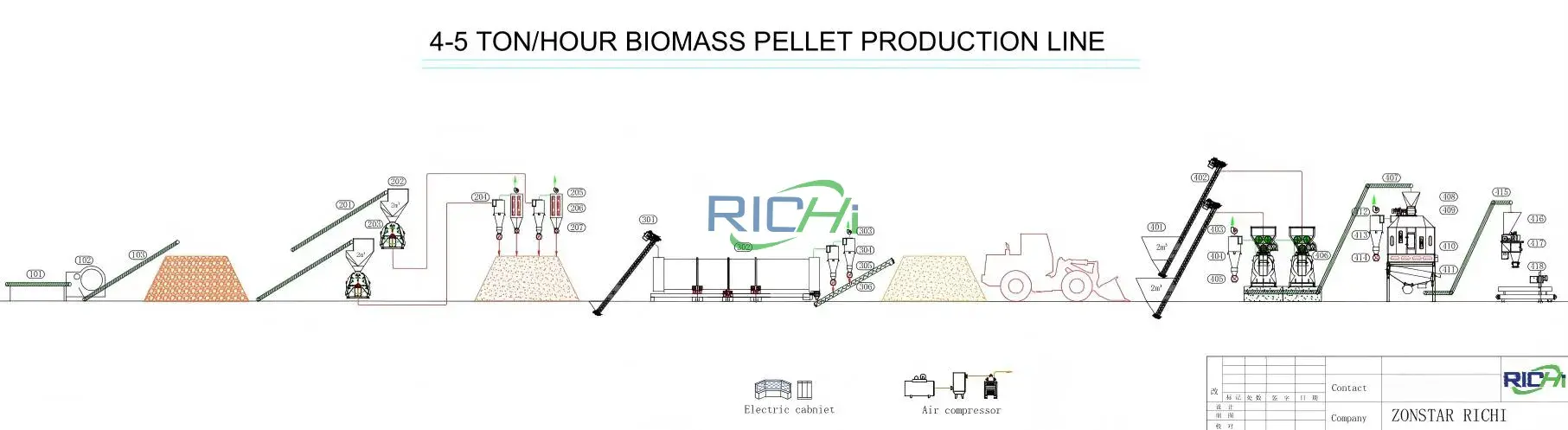

4-4.5TPH Biomass Pellet Production Line Flow Diagram

Before designing the entire process flow, our sales representatives and engineers will discuss your needs in detail. Based on your investment amount, factory floor area, and ceiling height, we will design the most suitable biomass pellet solution for you.

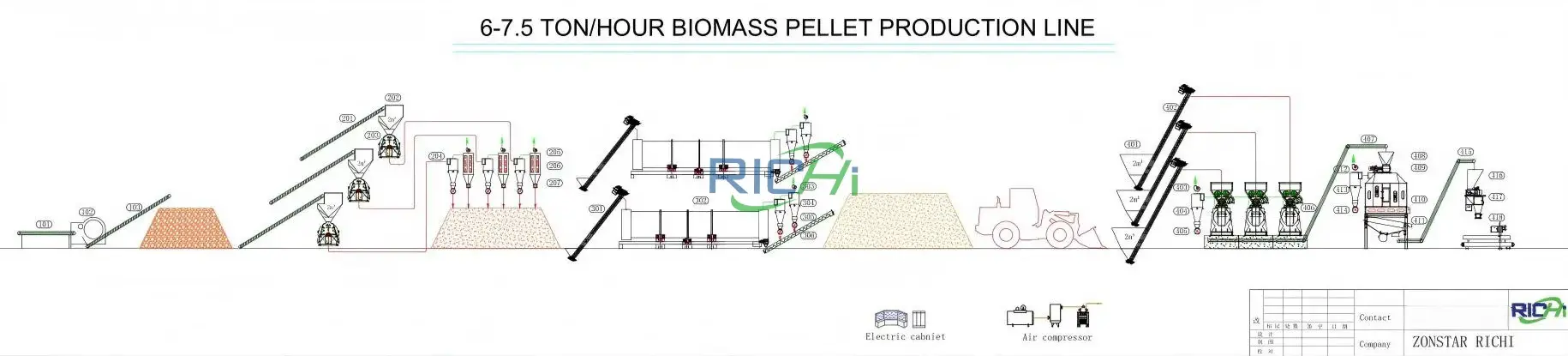

6-7.5TPH Biomass Pellet Production Line Flow Diagram

In the 6-7 ton biomass pellet production line, we add relevant equipment to the three most important sections to make the entire pelleting process smoother.

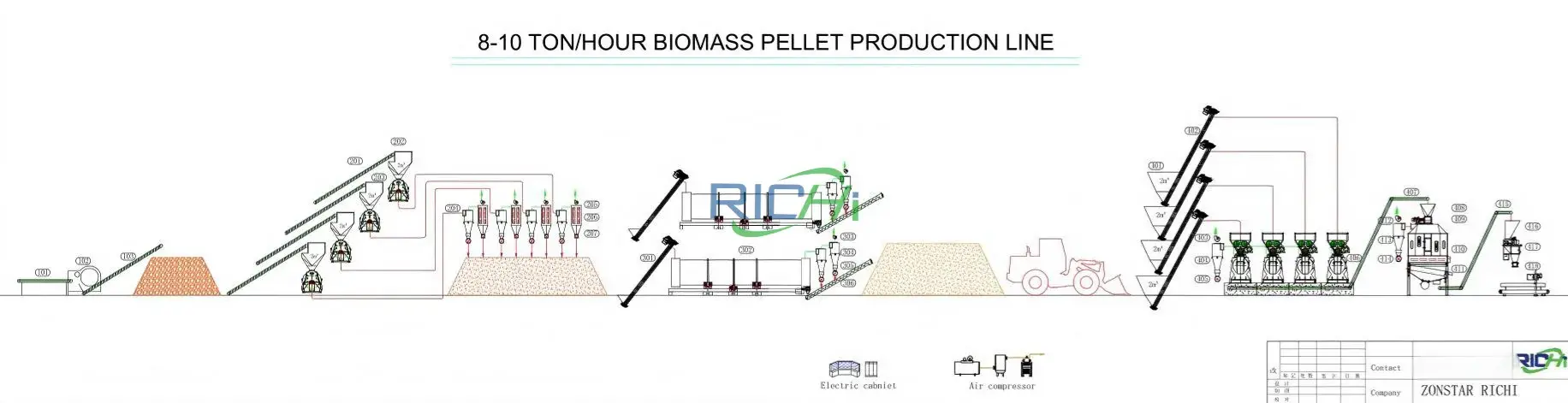

8-10TPH Biomass Pellet Production Line Flow Diagram

High-volume production inevitably requires the addition of more key equipment. We connect four water droplet pulverizers, pulse dust collectors, cyclone separators, pellet mills, and two flat drying drums in parallel to ensure the production of higher quality pellets.

about rICHI

RICHI continuously breaks through technological barriers in biomass pellet production, designing and building the most suitable biomass pellet production line for you.

Brand Promise

People-oriented, Quality First

enquiry@pelletmakingmachine.com

Agricultural waste biomass pellet production line

Forestry waste biomass pellet production line

If you are still unsure which type of production line is right for you, please contact us for the best solution.

Why Choose RICH?

For 30 years, RICHI has built over 500 biomass pellet production projects, covering more than 60 countries, with total sales exceeding $400 million.

RICHI Machinery provides customized biomass pellet production lines. We are not only a processor of biomass pellet production equipment but also a valuable partner in your biomass pellet plant construction.

Complete Process Support

30 years of technological accumulation allows RICHI to continuously research, develop, and innovate. Utilizing imported gearboxes, Siemens motors, and 42CrMo pressure rollers, we bring you a superior pelletizing experience.

Customized Solutions

RICHI Machinery particularly focuses on customer needs. We provide one-to-one customized production of exclusive biomass pellet production lines, thoroughly ensuring the machinery is best suited to your application.

Closed-Loop Consulting Services

RICHI provides professional services, starting from the initial consultation. After our engineers finalize the design and installation, our sales staff will periodically communicate with you to keep you updated on equipment technology.

Frequently Asked Questions

Building a suitable biomass pellet production line is not an easy task. If you want to choose a production line that suits your needs, you might find the following Q&A helpful.

1.What is the energy consumption of a biomass pellet production line?

+

RICHI has effectively optimized energy consumption through continuous technological innovation. Generally, the power consumption per ton of wood pellet production line is less than 81 kWh/t. The power consumption per ton of straw and rice husk pellet production line is 85-95 kWh/t. The power consumption per ton of forage pellet production line is 70-80 kWh/t.

In terms of output, generally, a 1-2 T/H biomass pellet production line consumes 80-90 kWh/t; a 3-5 T/H biomass pellet production line consumes 82-88 kWh/t; and an 8-10 T/H biomass pellet production line consumes 81 kWh/t.

2.Why build a biomass pellet production line?

+

Building biomass pellet production lines is a global development trend. RICHI offers a complete biomass pellet production line, from raw material crushing to finished product packaging, with capacities ranging from 0.5 tons to 40 tons. This allows you to invest with the highest cost-effectiveness and recoup your costs in the shortest possible time.

3.What makes RICHI biomass pellet production lines unique?

+

Customization and technological innovation are our most distinctive features.

We can provide one-on-one customized designs based entirely on your investment needs, factory requirements, and project timelines. Furthermore, over our 30 years of development, we have continuously innovated the materials and technologies of our pelletizing equipment and provide ongoing, permanent technical update support to both new and existing customers.

Choosing RICHI means choosing not only a biomass pellet production line, but also our extensive construction experience and a pelletizing partner with the greatest innovative potential.

4.What biomass pellet mills do you offer?

+

MZLH, FZLH, CZLH, and MSZLH series are all professional pellet mills we currently design and manufacture for biomass pellet production.

The MZLH series pellet mills are designed specifically for wood pellet production; the FZLH series pellet mills are designed specifically for waste pellet production; the CZLH series pellet mills are designed specifically for hay pellet production; and the MSZLH series pellet mills are designed specifically for cat litter pellet production.

5.My raw material is Caribbean pine, with an initial moisture content of approximately 50%. I want to produce high-quality 6/8 mm wood pellets that meet ENplus/DINplus standards. Can your biomass pellet production line meet my needs?

+

Absolutely. We have professional drying technology and extensive experience in building high-quality production lines.

Firstly, for raw materials with a moisture content of 50%, we use professional drying drums to effectively reduce the moisture content to 10-12%. Simultaneously, low-temperature drying technology prevents pine resin denaturation, ensuring a higher-quality finished product.

Secondly, regarding the quality control of the finished pellets, we will equip you with imported German alloy steel ring dies, paired with an automatic cutting system, ensuring that the die hole diameter of the finished pellets is precisely 6mm/8mm, and the pellet length meets ENplus standards. The entire specific process flow for your biomass pellet production line will be custom-designed by our engineers. For further information, please contact us or view related videos on our YouTube channel.