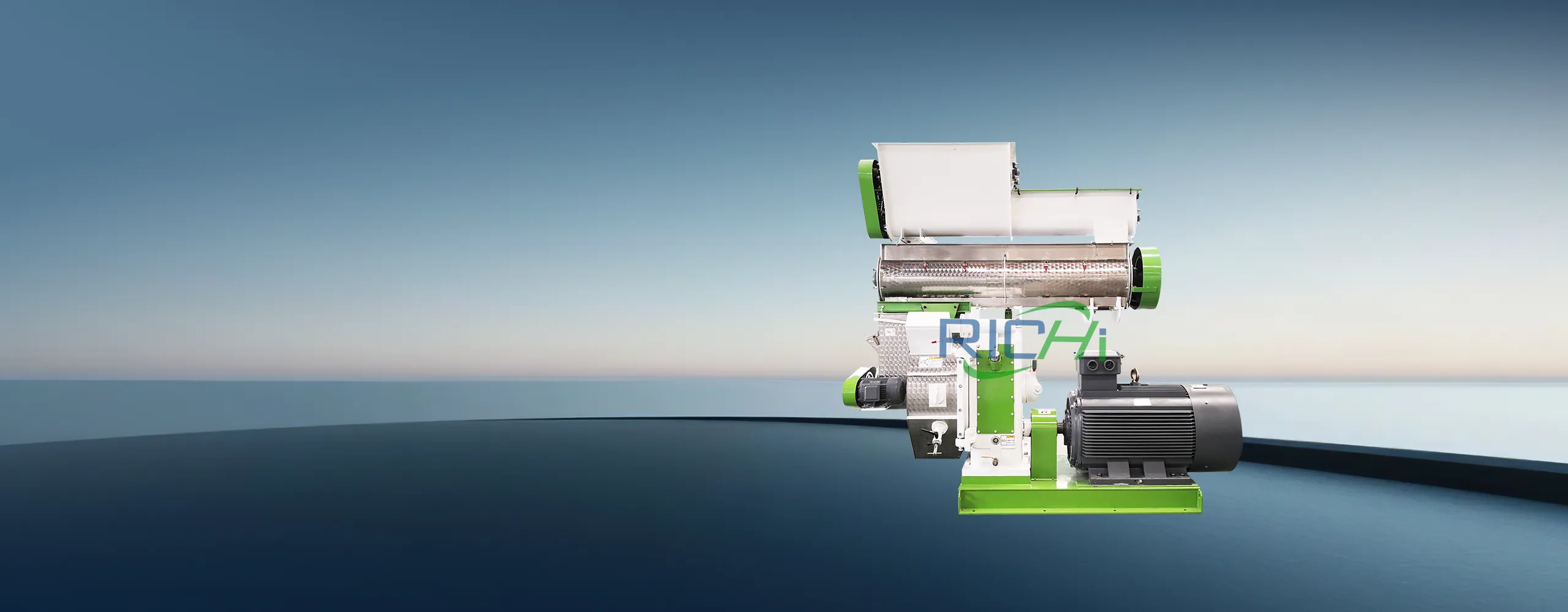

Alfalfa Pellet Machine For Sale

The Structure Composition Of Alfalfa Pellet Machine

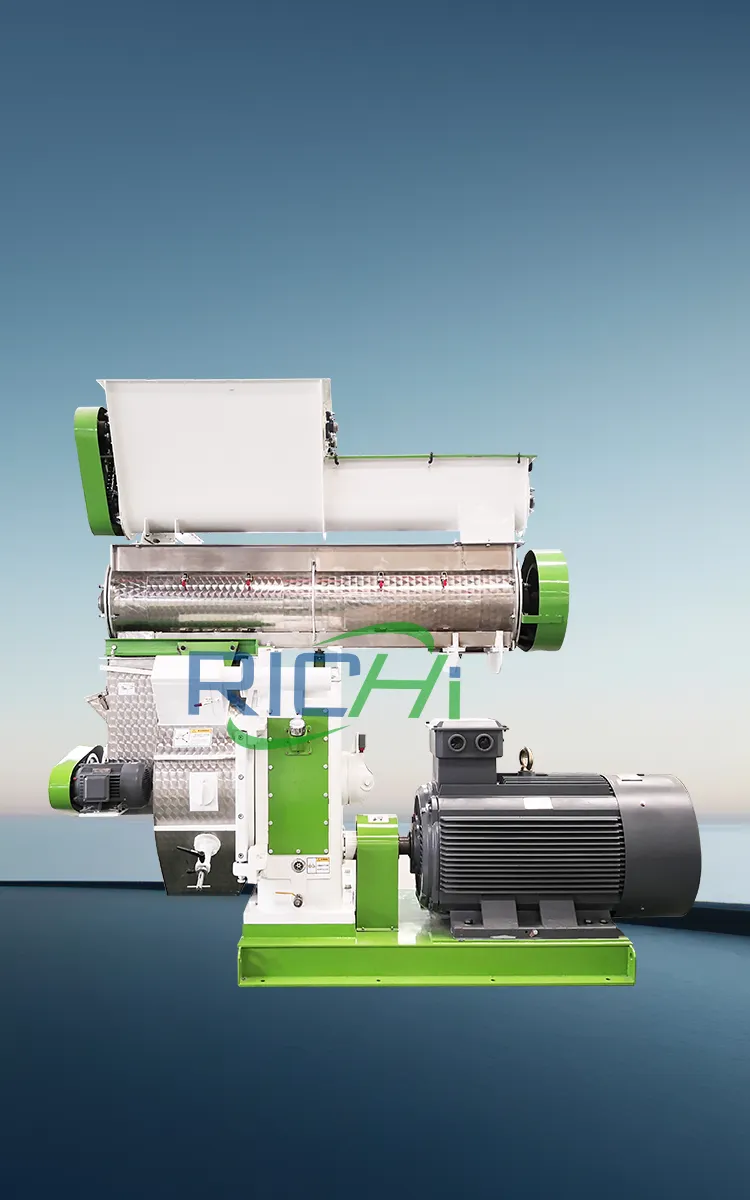

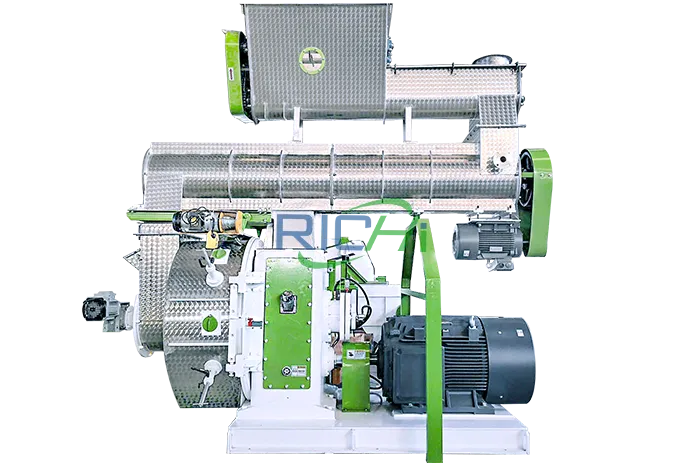

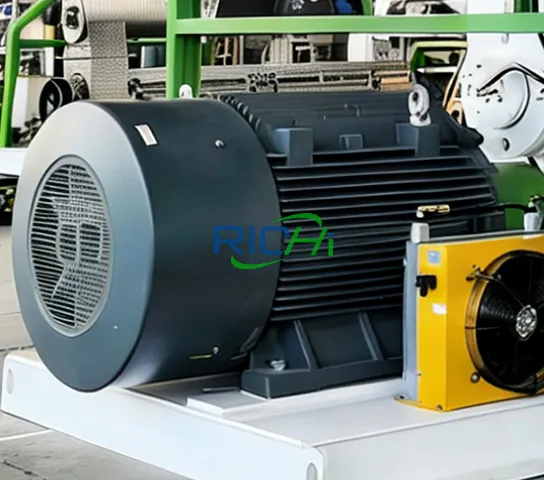

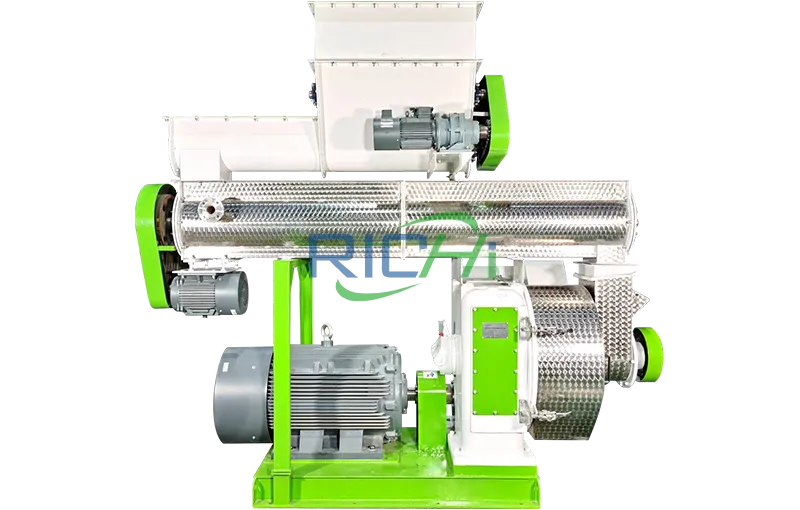

RICHI manufactures a diverse range of alfalfa pellet machines for sale, boasting an integrated structure that includes a variable-frequency feeder, conditioner, forced feeder, pelletizing chamber, cutter, and Siemens motor.

A detailed component diagram of the alfalfa pellet machine is provided below:

variable-frequency feeder

conditioning system

Turbine Motor

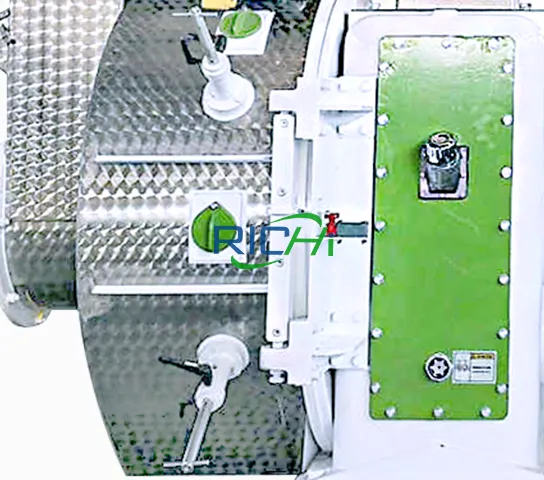

pelletizing chamber

cutter

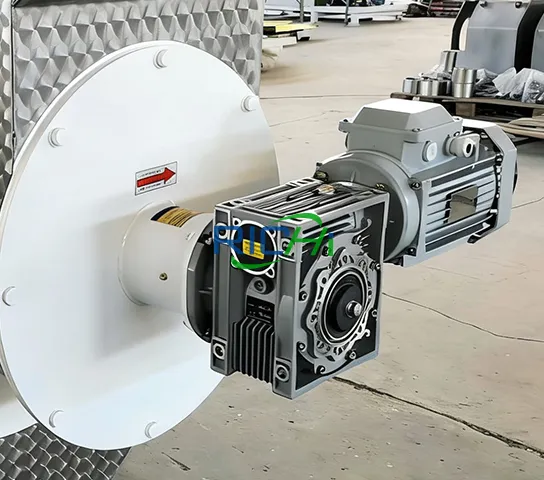

drive system

RICHI meticulously crafts high-quality alfalfa pellet machines for sale, with technological breakthroughs in grass meal pelleting processes. This enables the equipment to more effectively address the challenges posed by the unique moisture content of alfalfa meal and its high processing difficulty.

Alfalfa Pellet Machine Model

To address the inherent characteristics of alfalfa—high fiber content and poor flowability—RICHI Machinery has developed multi-capacity alfalfa pellet machines for sale, providing you with a wider range of options.

| Alfalfa Pellet Machine For Sale | ||||||

| Model | CZLH320 | CZLH350 | CZLH420 | CZLH520 | CZLH678 | CZLH768 |

| Main Motor Power (kW) | 22 | 37 | 90 | 132 | 185 | 250 |

| Arch-Breaking Feeder Power (kW) | 2.2 | 2.2 | 3 | 3 | 3 | 4 |

| Forced Feeder Power (kW) | 0.75 | 0.75 | 1.5 | 1.5 | 1.5 | 1.5 |

| Ring Die Inner Diameter (mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished Particle Diameter (mm) | 4~12 | |||||

| Output (T/H) | 0.5-0.6 | 1.0-1.2 | 1.8-2.0 | 2.8-3.0 | 4-5 | 6-8 |

| Equipment Configuration | Ring die material: stainless steel Door cover of granulation room: 6mm /SUS304 Feed chute: 3mm /SUS304 Gear box: HT250 Gear: 42CrMo Gear shaft: 20CrMnTi Spindle: 42CrMo Empty shaft: 42CrMo Bearing: Import Oil seal: Germany/Taiwan Overload mechanical protection: safety pin Serpentine spring coupling drive Using Siemens Motor | |||||

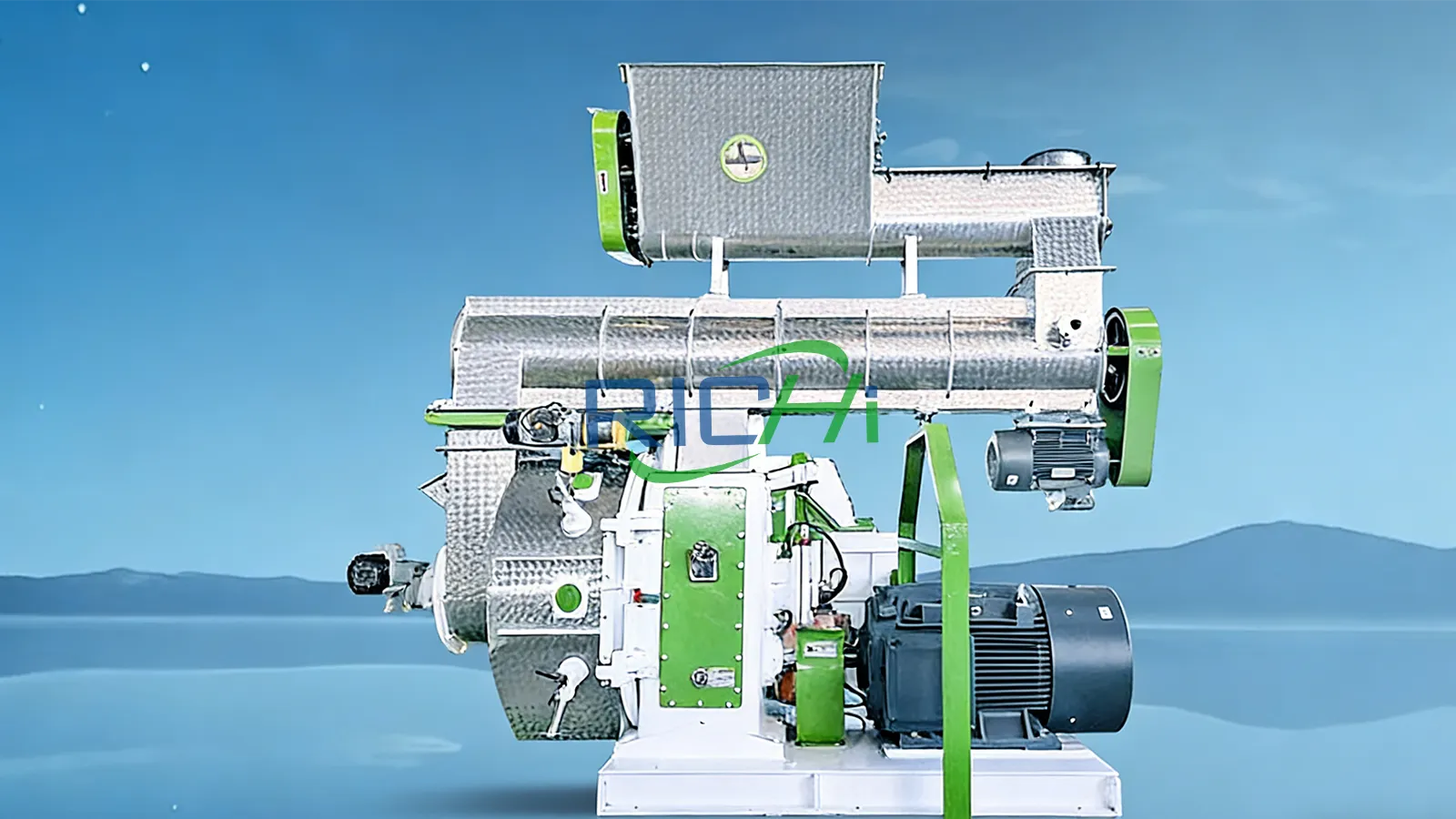

Clear Structure of the Alfalfa Pellet Machine

Working Principle

The working principle of the alfalfa pellet making machine is based on the dual effects of mechanical extrusion molding and thermoplastic deformation.

The ground material is fed into the conditioner through a variable-frequency feeder, where it undergoes high-temperature and high-pressure conditioning to become a paste-like substance, which then enters the pelletizing chamber of the alfalfa pellet machine for sale.

Inside the pelletizing chamber, the material is compacted by the rotation of the ring die and the pressing action of the rollers. After being cut by the cutter, it forms finished pellets, which are discharged through the outlet.

Key Technology Of Alfalfa Pellet Machine

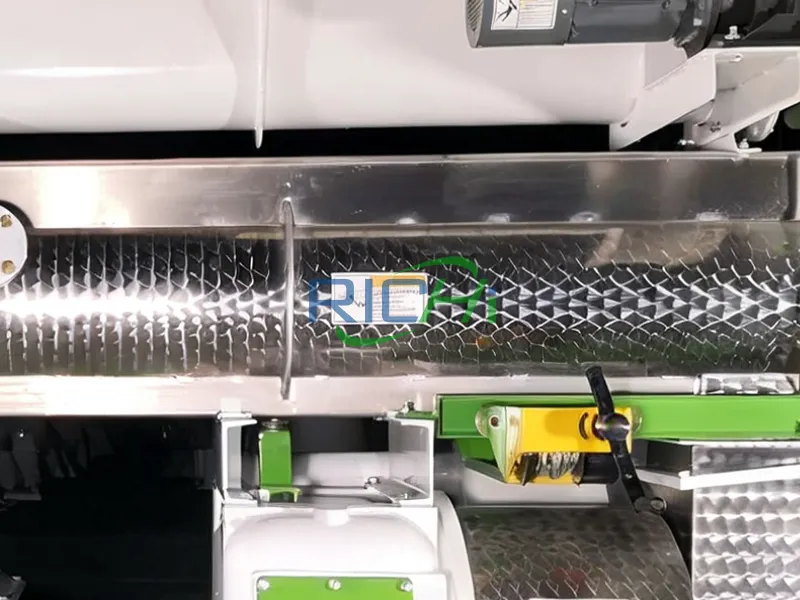

Anti-Bridging Variable-Frequency Feeder—Ensuring Smoother Alfalfa Pelleting

Due to its tendency to bridge and poor flowability, alfalfa raw material can form a “bridge” during feeding, which may lead to interruptions, uneven feeding, and fluctuations in the main motor’s current.

RICHI equips its alfalfa pellet machine for sale with dual anti-bridging shafts paired with a single feed shaft, ensuring the uniform and stable discharge of bulk materials. This, in turn, guarantees smoother feeding into the pelletizing chamber and more consistent pellet output.

304 Stainless Steel Conditioner—Higher Material Gelatinization

Alfalfa raw material contains high fiber content, making it difficult to press into shape. It can also cause wear to the ring die, reducing the equipment’s service life.

RICHI constructs the conditioners of its alfalfa pellet machine for sale from 304 stainless steel, facilitating thorough mixing of steam and materials. This not only effectively boosts sterilization efficiency but also enhances pellet binding capacity and forming performance, while significantly reducing ring die wear.

Forced Feeder—Easily Solving Accumulation Issues

When alfalfa raw material drops vertically through the feed chute, its lightweight nature makes it difficult to automatically enter the pelletizing chamber, requiring external force to achieve complete feeding.

The RICHI alfalfa pellet machine for sale is equipped with a forced feeder, which actively and mechanically intervenes to push loose, lightweight alfalfa powder into the pelletizing chamber, maximizing adaptability to the raw material.

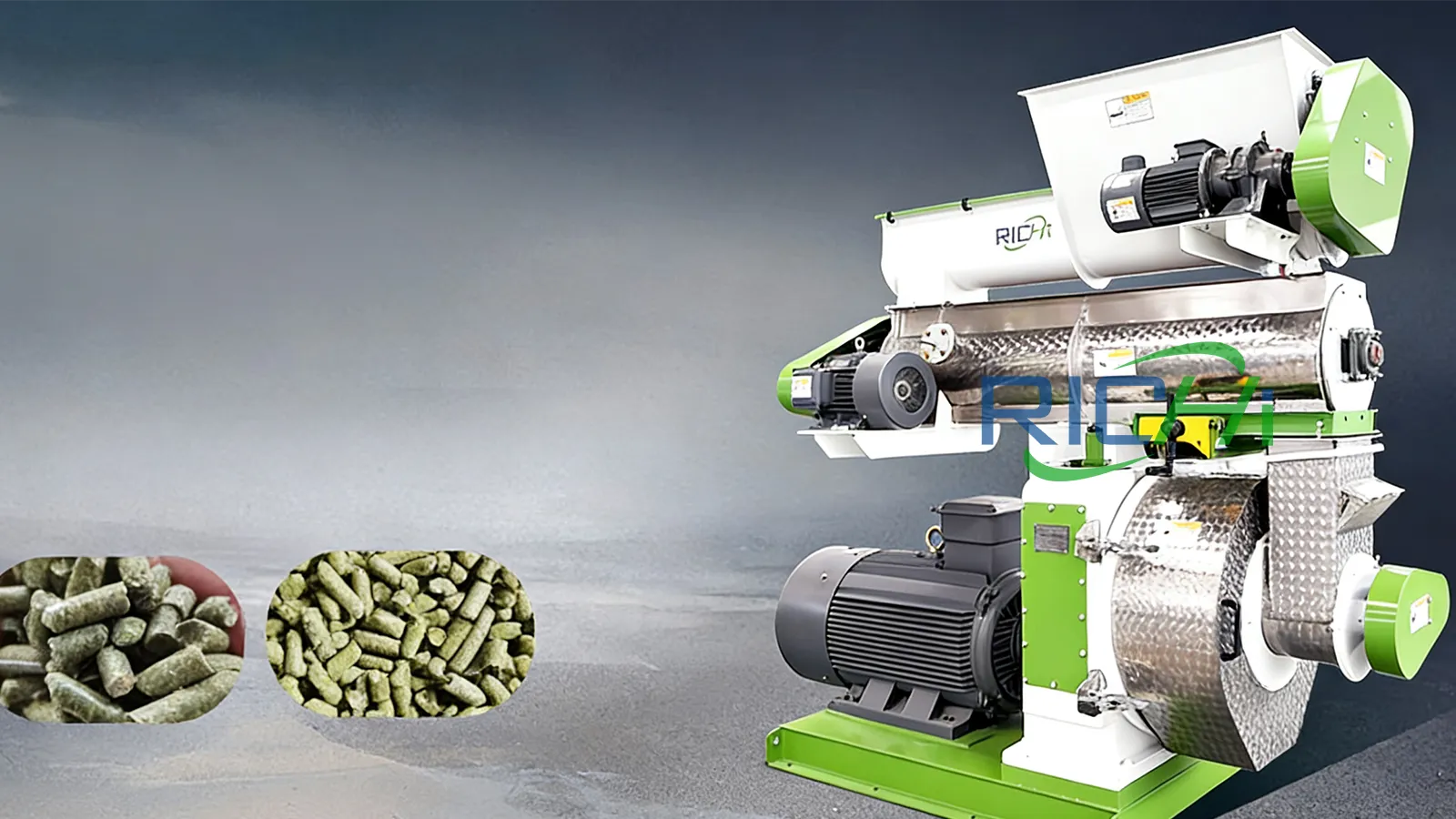

Features and Advantages of Alfalfa Pellet Machines

Versatile Adaptability

RICHI manufactures a diverse range of alfalfa pellet machines for sale, which can accommodate both single-ingredient production and multi-ingredient proportional blending—providing you with a wider range of pelleting solutions.

Superior Quality

RICHI’s alfalfa pellet machines for sale are equipped with a stainless steel body and high-precision gear transmission. The pelletizing chamber adopts a ring die fabricated from 42CrMo alloy steel—effectively reducing maintenance requirements and prolonging the equipment’s service life.

Premium Pellet Quality

By optimizing the ring die design and installation process of its alfalfa pellet machines for sale, RICHI has adopted a quick-release clamp mounting structure. This effectively minimizes ring die cracking, increases hourly output, and improves the quality of finished pellets.

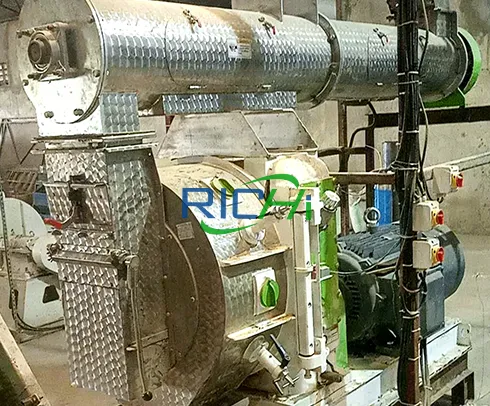

Related cases of Alfalfa Pellet Mill

The RICHI alfalfa pellet machine for sale is suitable for animal feed mills, farms, alfalfa growers, organic fertilizer plants, biomass fuel plants, and more. Below we showcase real-world cases of our alfalfa pellet mills in countries such as South Africa, Kazakhstan, Russia, Australia, and others.

15-20 T/H Alfalfa Pellet Machine for Sale South Africa

In this project, the RICHI alfalfa pellet machine is mainly used to process raw materials containing 30-40% alfalfa for the production of biomass fuel pellets.

- Output (t/h) : 15-20

- Power (kW) : 185

- Model : CZLH678

1-1.2 T/H Alfalfa Pelleting Machine In Kazakhstan

In this project, the RICHI alfalfa pellet mill is mainly used to process raw materials containing 50% alfalfa for the production of cattle and sheep feed, intended for on-farm use.

- Output (t/h) : 1-1.2

- Power (kW) : 22

- Model : CZLH320

20 T/H Alfalfa Pellet Machine For Sale Russia

In this project, the RICHI alfalfa pellet machine is mainly used to process raw materials containing 40-80% alfalfa, supplemented with corn, wheat, and other grains.

- Output (t/h) : 10

- Power (kW) : 250 × 2

- Model : CZLH768 × 2

10 T/H Alfalfa Pellet Machine for Sale Australia

In this project, the RICHI alfalfa pellet machine is mainly used to process raw materials containing 20-30% alfalfa for the production of fuel pellets, providing energy for local use.

- Output (t/h): 10

- Power (kW): 90 × 2

- Model : CZLH420 × 2

8-10 T/H Alfalfa Pellet Machine for Sale Senegal

In this project, the RICHI alfalfa pellet machine is mainly used to process raw materials containing 10% alfalfa for the production of various livestock and poultry feeds.

- Output (t/h): 8-10

- Power (kW): 90

- Model : CZLH420

5 T/H Alfalfa Pellet Machine for Sale New Zealand

In this project, the RICHI alfalfa pellet machine is mainly used to process raw materials containing 70% alfalfa for the production of cattle and sheep feed, with a total investment of USD 180,000.

- Output (t/h): 5

- Power (kW): 132

- Model : CZLH520

4 T/H Alfalfa Pellet Mill For Sale Canada

In this project, the RICHI alfalfa pellet machine is mainly used to process alfalfa-based feed, serving as an effective addition to the full-range feed production line of this large feed mill.

- Output (t/h): 4

- Power (kW): 132

- Model : CZLH520

3-4 T/H Alfalfa Pellet Machine for Sale Mexico

In this project, the RICHI alfalfa pellet machine is mainly used for alfalfa feed pellets and alfalfa fuel pellets, intended for sale as both feed and fuel.

- Output (t/h): 3-4

- Power (kW): 132

- Model : CZLH520

6-8 T/H Alfalfa Pellet Machine for Sale Qatar

In this project, the RICHI alfalfa pellet machine is mainly used to process raw materials based on alfalfa and grains for the production of livestock feed.

- Output (t/h): 6-8

- Power (kW): 132

- Model : CZLH520

Related Videos

When customers purchase alfalfa pelletizer machines, they often have different needs. The alfalfa pellet machine for sale produced by RICHI can be used to produce feed pellets, biomass fuel pellets, and fertilizers. Next, we will present three alfalfa pellet machines from Argentina, Tajikistan, and Tanzania, which produce feed pellets, biomass fuel pellets, and fertilizer, respectively.

The Entire Process Of Alfalfa Pellet Machine

The alfalfa pellet machine is a key stage—but not the entirety—of alfalfa pellet production. The entire pelleting process is continuous and can be divided into the following seven stages:

Raw Material Cleaning and Screening

01

This stage primarily removes impurities and foreign objects from the alfalfa raw material to ensure higher alfalfa content while preventing damage to the machine from metallic contaminants.

Crushing

02

When the raw material is not alfalfa powder but in stalk form, a corresponding crushing process is required. The crushing system may not achieve the desired result in a single step; sometimes, multiple types of crushers are used to optimize the pelletizing outcome.

Drying

03

The optimal moisture content for alfalfa raw material during pelletizing is 14%–16%. If the raw material exceeds this moisture level, a drying stage is necessary to reduce the moisture content.

Mixing

04

When the raw material used in the alfalfa pelleting machine is a mixture of alfalfa and other materials, a mixer is required to achieve uniform blending of the materials.

Pelletizing

05

After receiving the pre-processed raw material, the alfalfa pellet machine for sale conditions it through a conditioner and compresses it in the pelletizing chamber, transforming the material into finished pellets.

Cooling and Screening

06

The pellets produced by the alfalfa pellet machine for sale are at a high temperature, making them unsuitable for storage and packaging. Their hardness may also not meet quality standards. Therefore, they must be cooled using a cooler and screened to remove fines.

Packaging

07

The cooled and screened finished pellets undergo a series of processes—weighing, filling, and sealing—using RICHI’s fully automated packaging system.

Why Choose RICHI?

RICHI Machinery delivers premium quality, crafting alfalfa pellet machines for sale that fully meet your expectations. With professional expertise and refined craftsmanship, we accompany you in building a better alfalfa pellet production line.

More Professional

RICHI specifically designs its alfalfa pellet machine for sale to handle lightweight raw materials such as alfalfa and forage, delivering high-quality equipment that is better suited for alfalfa pellet production.

More Durable

RICHI equips its alfalfa pellet machine for sale with a stainless steel protective body and upgrades multiple core components to alloy steel—rendering the equipment more precise in operation and durable in service.

Customization

From consultation and design through post-construction, RICHI assigns professionals for your needs, tailoring the process to create the most satisfactory, exclusive pelleting solution for you.

Frequently Asked Questions

Choosing a high-performance and durable alfalfa pellet machine is no simple task—you may encounter many questions along the way. Here, we address some common questions regarding RICHI Machinery’s pellet machines for sale to help clarify your decision:

Can the alfalfa pellet machine for sale process other materials, such as corn stalks or wood chips?

+

Absolutely. Our equipment is multi-functional and versatile. You only need to replace the ring die and adjust the parameters to produce forage pellets, straw pellets, biomass pellets, and more. Please note: Different materials require specific configurations for compression ratio, mold aperture, and cutter length. RICHI will provide you with a complete parameter table and operational training.

How does the ratio of alfalfa to grains affect the capacity of the alfalfa pellet machine for sale?

+

The higher the proportion of alfalfa or forage in the formula, the lower the output of the pellet machine; conversely, a higher grain content increases output. Please provide your exact raw material formula, and our engineers will accurately estimate the actual production capacity and recommend the most suitable model. For example, the CZLH420 model (rated 2–10 tons/hour) may only achieve 1.5–2 tons/hour when processing 100% pure alfalfa.

Can you provide videos and customer cases of the alfalfa pellet machine operating in our region?

+

Yes, as long as your required output for the alfalfa pellet machine for sale is not less than 500 kg/hour, our engineers can tailor an economical solution for you. We will optimize the process and remove non-essential equipment (such as automated packaging systems or boilers) to fit your budget, while ensuring core pelletizing performance. Many customers in Argentina and Indonesia who chose our alfalfa pellet machine for sale started with 1–1.5 ton/hour production lines and recouped their investment within 1–2 years.

My budget is limited. Can you customize a small-scale production line for a startup?

+

We can design a small-scale production line for you. Regarding the alfalfa pellet machine for sale, its direct starting current is approximately 6 times the rated current. Therefore, we recommend using a diesel generator rated at 150 kVA or higher to power it.

What is the required moisture content of alfalfa raw material before pelleting?

+

Regarding the alfalfa pellet machine for sale, the optimal moisture content for alfalfa before pelleting is 14%–16%. If your raw material has high moisture (e.g., fresh alfalfa can reach 50%), we will add a rotary drum dryer to reduce it to 15%–18% before fine-grinding. For dry alfalfa (moisture <20%), it can be directly crushed and pelletized. For smooth operation of the alfalfa pellet machine for sale, moisture control is crucial—too high can clog the die holes, and too low will reduce output and increase dust.